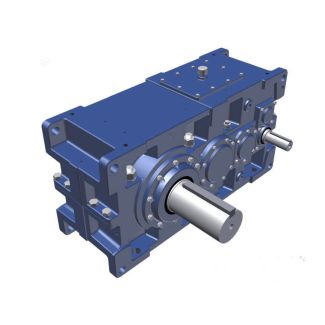

H4-SH-13-A flender eupex n Helical gear reducers H4

In stock

SKU

H4-SH-13-A

$30,000.00

Flender/Flender Gear Units/Helical gear reducers H4

evented by liningwith polyethylene or greaseproof paper to coating with microcrystalline wax and polyeth-ylene (Brown, . 4.3 Plastics Since the 1s there has been tremendous increase in the use of plastics, replacing traditional packaging materials such as glass, metal, and

1s there has been tremendous increase in the use of plastics, replacing traditional packaging materials such as glass, metal, and  paper. The raw materials forplastics are petroleum, natural gas, and coal. They are formed by polymerization methodthat creates linkages between

paper. The raw materials forplastics are petroleum, natural gas, and coal. They are formed by polymerization methodthat creates linkages between  many small repeating chemical units (monomers) to formlarge molecules or polymers. Examples of common plastic materials and their monomer Packaging

many small repeating chemical units (monomers) to formlarge molecules or polymers. Examples of common plastic materials and their monomer Packaging  of Fruits and Vegetables 5 Fig. 1 Various types of corrugated board construction: ( utesingle wall, ( ute single wall, ( utesingle wall, ( and Cdouble wall, and ( , , and triple wall. (Courtesy of Smurt-MBI, Montreal, Quebec, Canada.) building blocks are listed in Table 2. Many plastics contain very small amounts of addi- tives, such as plasticizers, antioxidant, lubricants, antistatic agents, heat stabilizers, and UV stabilizers. These are added to facilitate processing of plastics or to impart desirableproperties to them. For example, plasticizers are added to soften plastics, thus makingthem more exible and less brittle for use in cold climates or with frozen stored products.According to Fellows (, the advantages of plastics as packaging materials are theirrelatively low cost, good barrier properties against moisture and gases, heat sealablity to prevent leakage of contents, suitability for high-speed lling, wet and dry strength, suit- ability for printing, ease in handling and convenience for the manufacturer, retailer, andconsumer; addition of little weight to the product and close to the shape of the food,thereby wasting little space during storage and distribution. Plastics may be made as exible lms or as semirigid and rigid containers to meet the varied packaging and processing requirements of food. Plastic lms are made with wide range of mechanical, optical, heat sealable, and b

of Fruits and Vegetables 5 Fig. 1 Various types of corrugated board construction: ( utesingle wall, ( ute single wall, ( utesingle wall, ( and Cdouble wall, and ( , , and triple wall. (Courtesy of Smurt-MBI, Montreal, Quebec, Canada.) building blocks are listed in Table 2. Many plastics contain very small amounts of addi- tives, such as plasticizers, antioxidant, lubricants, antistatic agents, heat stabilizers, and UV stabilizers. These are added to facilitate processing of plastics or to impart desirableproperties to them. For example, plasticizers are added to soften plastics, thus makingthem more exible and less brittle for use in cold climates or with frozen stored products.According to Fellows (, the advantages of plastics as packaging materials are theirrelatively low cost, good barrier properties against moisture and gases, heat sealablity to prevent leakage of contents, suitability for high-speed lling, wet and dry strength, suit- ability for printing, ease in handling and convenience for the manufacturer, retailer, andconsumer; addition of little weight to the product and close to the shape of the food,thereby wasting little space during storage and distribution. Plastics may be made as exible lms or as semirigid and rigid containers to meet the varied packaging and processing requirements of food. Plastic lms are made with wide range of mechanical, optical, heat sealable, and b| Model Type | Helical gear reducers H4 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 1400.000000 |

| Ratio Range | 1 : 100…355 |

| Low Speed Output | Solid shaft with parallel key acc. to DIN 6885/1 |

| Nominal Torque | 90700 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Flender Svenska AB |

| Country of Manufacture | China |

| Data Sheet & Drawings | H4-SH-13-A flender eupex n Helical gear reducers H4 |