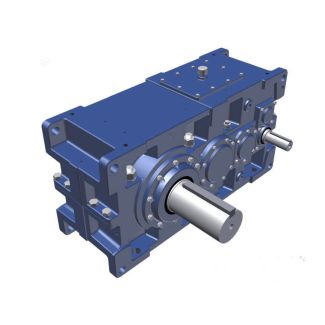

H4SH-13-C flender shop Helical speed reduction gearboxes H4

In stock

SKU

H4SH-13-C

$30,000.00

Flender/Flender Gear Units/Helical speed reduction gearboxes H4

eves higher values of gear ratio. However, there are some manufacturers who produce gear reducers with smaller or larger load capacity for higher or lower gear ratio, within the same axis height. This paper deals with analysis of justification of

capacity for higher or lower gear ratio, within the same axis height. This paper deals with analysis of justification of  applying two gear sets, especially in the case when so - called intermediate sizes of gear reducer are not used.

applying two gear sets, especially in the case when so - called intermediate sizes of gear reducer are not used.  1 Introduction Axis heights of universal gear reducers are prescribed according to the standard row R2. Since this row is

1 Introduction Axis heights of universal gear reducers are prescribed according to the standard row R2. Since this row is  very dense, for while manufacturers of universal gear reducer produced reducers with axis height from standard ro R1 (these numbers belong to the standard row R. But soon they increased axis heights in order to increase gear rat io, and now reducers are produced with axis height in standard row R2/2. In the area of the most used gearbox sizes, some manufacturers produce so-called intermediate sizes with the axis heights in row R2. There is no standard which defines particular load capacities within different sizes (axis heights), so manufacturers have open fi eld for defining load capacities [1]. Load capacity values of leading gear reducer manufacturers are followed, so that particular interchangeability could be provided. In order to achieve some adva ntage at the market, smaller manufacturers of gear reducers produce reducers with smaller torque capacity, but with higher gear ratios. In this way they are able to provide cheaper lower stage gearbox in particular segment of gear ratios. However, leading gearbox manufacturers recognized this occurrence, and started to offer two sets of gear pair within the same size, and also even in the same of gearbox housing. With this two gear sets, they provide particular gear ratio for larg er and for smaller load capacity, so that they annulled advantage of smaller gear reducer manufacturers [2]. * Corresponding author: racmil Siemens Flender uns.ac.rs DOI: 1.1/ ,0 ( 7 1 1 MA

very dense, for while manufacturers of universal gear reducer produced reducers with axis height from standard ro R1 (these numbers belong to the standard row R. But soon they increased axis heights in order to increase gear rat io, and now reducers are produced with axis height in standard row R2/2. In the area of the most used gearbox sizes, some manufacturers produce so-called intermediate sizes with the axis heights in row R2. There is no standard which defines particular load capacities within different sizes (axis heights), so manufacturers have open fi eld for defining load capacities [1]. Load capacity values of leading gear reducer manufacturers are followed, so that particular interchangeability could be provided. In order to achieve some adva ntage at the market, smaller manufacturers of gear reducers produce reducers with smaller torque capacity, but with higher gear ratios. In this way they are able to provide cheaper lower stage gearbox in particular segment of gear ratios. However, leading gearbox manufacturers recognized this occurrence, and started to offer two sets of gear pair within the same size, and also even in the same of gearbox housing. With this two gear sets, they provide particular gear ratio for larg er and for smaller load capacity, so that they annulled advantage of smaller gear reducer manufacturers [2]. * Corresponding author: racmil Siemens Flender uns.ac.rs DOI: 1.1/ ,0 ( 7 1 1 MA| Model Type | Helical speed reduction gearboxes H4 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 1400.000000 |

| Ratio Range | 1 : 100…355 |

| Low Speed Output | Solid shaft with parallel key acc. to DIN 6885/1 |

| Nominal Torque | 90700 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Flender Brasil Ltda |

| Country of Manufacture | Chile |

| Data Sheet & Drawings | H4SH-13-C flender shop Helical speed reduction gearboxes H4 |