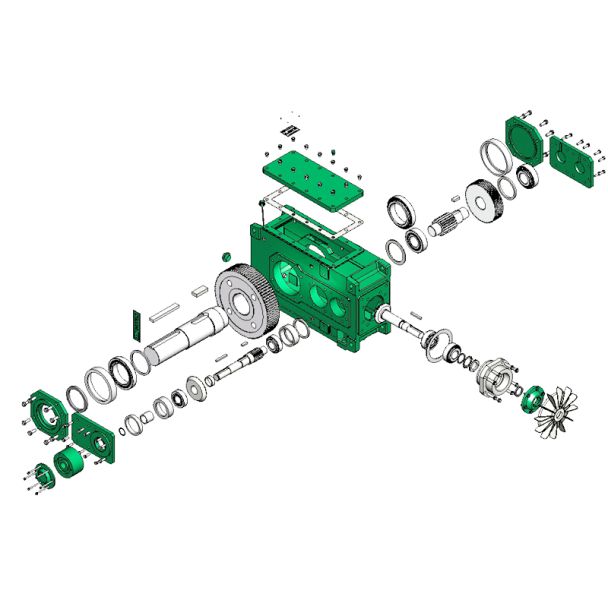

Helical gearbox H4 G PGD x f PG kW Fan and cooling coil possiblePG H4-FH-26-D

In stock

SKU

H4-FH-26-D

$282,857.14

Flender/Flender Gear Units/Helical gearbox H4

kistan 9Nigeria 5 Philippines 4 Chile 4 Haiti 2World 2,4 Source : From Ref. 1. 8 Eipeson and Ramteke Table 5 Different Components Obtained During Mango PulpExtraction Component Percentage Mango pulp 4 Peels 1 Pulper waste 1Stones (seeds) 1 Source

5 Different Components Obtained During Mango PulpExtraction Component Percentage Mango pulp 4 Peels 1 Pulper waste 1Stones (seeds) 1 Source  : From Ref. 5. operation, coarse mango pulp ows out and the peel along with the stones (seeds) are ejected.

: From Ref. 5. operation, coarse mango pulp ows out and the peel along with the stones (seeds) are ejected.  The coarse pulp is again passed through pulper tted with ner sieve (0.5-mm-diameter opening) to recover nished pulp. The ber

The coarse pulp is again passed through pulper tted with ner sieve (0.5-mm-diameter opening) to recover nished pulp. The ber  portion along with some quantityof adhering pulp is rejected as pulper waste. The approximate proportions of the differentcomponents are given in Table 5. Extensive work has been done on characterization of the waste components and preparation of value-added products from them. Some of the aspects have been reviewed(5,. 2.5.1 Peel Waste Mango peel along with pulper waste sometimes referred to as peel waste constitutes 2% 3%. The peel waste is good source of sugars and pectin and also contains substantial quantities of protein, tannins, and crude ber. 2.5.2 Mango Peel Pectin Srirangarajan and Shrikhande ( extracted and characterized pectin from three varieties of mango, viz., Alphonso, Langra, and Dashehari. The quality of pectin was comparable to that of orange peel pectin. Tandon and coworkers ( showed that the yield of pectin from Dashehari varieties of mango was dependent upon the method of extraction. Whereas hydrochloric acid extrac- tion yielded 9.6%, the yield was 1.9% by sodium hexameta phosphate. They alsoshowed that the yield and quality of pectin were better from ripe than immature mangoes.Yu and Delvalle (, however, have shown that pectin yield from peels of partially ripe mangoes was higher (1.7%) than that from fully ripe mangoes (1.9%). The data on the yield and characteristics of pectin extracted from the peels of different varieties of mangoesshow varietal variations (; in general, the quality is suitable for food and pharmaceuticalpurposes. On dry weight basis, th

portion along with some quantityof adhering pulp is rejected as pulper waste. The approximate proportions of the differentcomponents are given in Table 5. Extensive work has been done on characterization of the waste components and preparation of value-added products from them. Some of the aspects have been reviewed(5,. 2.5.1 Peel Waste Mango peel along with pulper waste sometimes referred to as peel waste constitutes 2% 3%. The peel waste is good source of sugars and pectin and also contains substantial quantities of protein, tannins, and crude ber. 2.5.2 Mango Peel Pectin Srirangarajan and Shrikhande ( extracted and characterized pectin from three varieties of mango, viz., Alphonso, Langra, and Dashehari. The quality of pectin was comparable to that of orange peel pectin. Tandon and coworkers ( showed that the yield of pectin from Dashehari varieties of mango was dependent upon the method of extraction. Whereas hydrochloric acid extrac- tion yielded 9.6%, the yield was 1.9% by sodium hexameta phosphate. They alsoshowed that the yield and quality of pectin were better from ripe than immature mangoes.Yu and Delvalle (, however, have shown that pectin yield from peels of partially ripe mangoes was higher (1.7%) than that from fully ripe mangoes (1.9%). The data on the yield and characteristics of pectin extracted from the peels of different varieties of mangoesshow varietal variations (; in general, the quality is suitable for food and pharmaceuticalpurposes. On dry weight basis, th| Model Type | Helical gearbox H4 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 13200.000000 |

| Ratio Range | 1 : 112…400 |

| Low Speed Output | Flanged shaft |

| Nominal Torque | 1030000 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Flender de Mexico, S.A. de C.V. |

| Country of Manufacture | Turkmenistan |

| Data Sheet & Drawings | Helical gearbox H4 G PGD x f PG kW Fan and cooling coil possiblePG H4-FH-26-D |