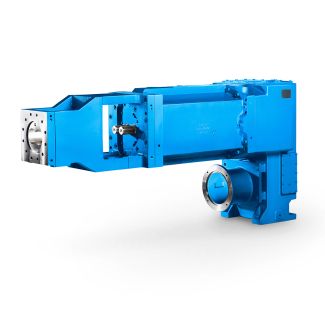

Helical gear Reduction Box H4 ooling adequate Cooling coil Waterairoil cooler H4-FH28A

In stock

SKU

H4-FH28A

$379,285.71

Flender/Flender Gear Units/Helical gear Reduction Box H4

knowledge of our products: this know-how will consistently represent the best ervice olution to resolve any service issue and to advise our customers. services Retrofit and Revamping : we optimize as major piece of rot ating equipment, gears are designed

advise our customers. services Retrofit and Revamping : we optimize as major piece of rot ating equipment, gears are designed  for infinite life time and are generally product with little replacement issues. Flender-Graffenstaden is active in upgrading older gearboxes in

for infinite life time and are generally product with little replacement issues. Flender-Graffenstaden is active in upgrading older gearboxes in  order to provide our customers with best cost /delivery solution and the additional operation time for existing geared equipment. Our

order to provide our customers with best cost /delivery solution and the additional operation time for existing geared equipment. Our  aim is to: Provide life cycle extension Increase power rating Reduce power losses Increase the reliabilit and the availability Moderniz , improve efficiency and power consumption enovation and upgrading of gearboxes from Flender-Graffenstaden Drop in replacement of gearbo xes from competitor engineering Design replacement gearbo xes to fit an existing foundationFlender-Graffenstaden supports the owners of the following brands : Flender-Graffenstaden, Graffenstaden Engrenages, ciT lcatel, . . .. with complete set of spare parts including : Gear set : bull gears and pinion shaf ts, single helical or double helical gear, pinions teeth are case hardened, bull gear teeth are either, case hardened, nitrided or through hardened, high precision grinding. earing : oil pressure lubricated 2 or 4 lobes, offset halves, tilting pads bearings, and adjustable bearing for optimized tooth contact pattern. Oil seal : labyrinth oil seal ccessory : clutch, coupling, oil pump, turning devices Instr umentation : temperature and vibration probes. Most of those parts are tailor made and not available on the shelf. Only Flender-Graffenstaden genuine parts can guarantee full interchan-geability and trouble free operation. Original spare parts : we inspect, we repair another duty of Flender-Graffenstaden consists in supporting and training our customers on ou

aim is to: Provide life cycle extension Increase power rating Reduce power losses Increase the reliabilit and the availability Moderniz , improve efficiency and power consumption enovation and upgrading of gearboxes from Flender-Graffenstaden Drop in replacement of gearbo xes from competitor engineering Design replacement gearbo xes to fit an existing foundationFlender-Graffenstaden supports the owners of the following brands : Flender-Graffenstaden, Graffenstaden Engrenages, ciT lcatel, . . .. with complete set of spare parts including : Gear set : bull gears and pinion shaf ts, single helical or double helical gear, pinions teeth are case hardened, bull gear teeth are either, case hardened, nitrided or through hardened, high precision grinding. earing : oil pressure lubricated 2 or 4 lobes, offset halves, tilting pads bearings, and adjustable bearing for optimized tooth contact pattern. Oil seal : labyrinth oil seal ccessory : clutch, coupling, oil pump, turning devices Instr umentation : temperature and vibration probes. Most of those parts are tailor made and not available on the shelf. Only Flender-Graffenstaden genuine parts can guarantee full interchan-geability and trouble free operation. Original spare parts : we inspect, we repair another duty of Flender-Graffenstaden consists in supporting and training our customers on ou| Model Type | Helical gear Reduction Box H4 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 17700.000000 |

| Ratio Range | 1 : 112…400 |

| Low Speed Output | Flanged shaft |

| Nominal Torque | 1400000 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Flender Macneill Gears Ltd. |

| Country of Manufacture | United Kingdom |

| Data Sheet & Drawings | Helical gear Reduction Box H4 ooling adequate Cooling coil Waterairoil cooler H4-FH28A |