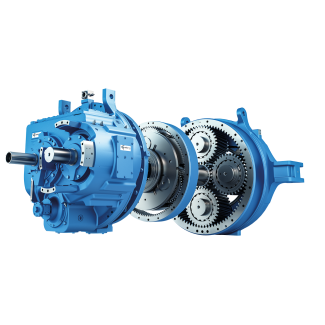

H4-DV8A lubricants only may be used You will find current Helical speed reduction gearboxes H4

In stock

SKU

H4-DV8A

$546,428.57

Flender/Flender Gear Units/Helical speed reduction gearboxes H4

In this context, methods such as the following were used: N2 low-temperature adsorption (BET surface area), mercury porosimetry (pore volume), CO adsor tion (precious metal surface area), scanning electron microscopy (nature of the catalyst suri)ace). 3. Results The goal of

CO adsor tion (precious metal surface area), scanning electron microscopy (nature of the catalyst suri)ace). 3. Results The goal of  the investigations conducted with precious metal-bearing catalysts was to find catalyst/reducing agent combinations which can selectively reduce NO to ,

the investigations conducted with precious metal-bearing catalysts was to find catalyst/reducing agent combinations which can selectively reduce NO to ,  at temperatures below 2", with surplus of 0, and in the presence of low SO, concentrations. Catalyst/ reducing agent combinations

at temperatures below 2", with surplus of 0, and in the presence of low SO, concentrations. Catalyst/ reducing agent combinations  of this kind could then be used at the farend of the flue gas path of power stations, .. after flue gas desulphurisation. Catalyst/reducing agent combinations suitable for industrial-scale application would have to meet the following criteria: 1. High selectivity in the presence of an 0 surplus in the context that the reducing agent is consumed predominantly by NO and less by 0, .. the reducing agent/NO ratio is ad- justed to correspond as far as possible to the stoichiometry of the NO reduction reaction. 2. High degree of NO and reducing agent conversion with low catalyst volumes, ;.. com- pliance with the NO waste as limits and low reducing agent loss (otherwise, separation and recirculation may possi%ly be necessary). 3. No formation of by-products (.. N2O). 4. Resistance of the active components and the catalyst carrier to sulphur and low SO2 oxida- tion and/or reduction activity on the part of the catalyst. The available results concernin the various precious metal catalyWreducing agent combina- tions showthat, when using -gee reducing agents, the high selectivityvalues targeted (Crite- rion were not reached in any case.The best selectivity values of 3Voare achieved according to the objective at temperatures below 2", but the desired high degree of NO and reduc- ing agent conversion (Criterion cannot then be realised. When using NH, as the reducing aaent, it must be assumed -as is k

of this kind could then be used at the farend of the flue gas path of power stations, .. after flue gas desulphurisation. Catalyst/reducing agent combinations suitable for industrial-scale application would have to meet the following criteria: 1. High selectivity in the presence of an 0 surplus in the context that the reducing agent is consumed predominantly by NO and less by 0, .. the reducing agent/NO ratio is ad- justed to correspond as far as possible to the stoichiometry of the NO reduction reaction. 2. High degree of NO and reducing agent conversion with low catalyst volumes, ;.. com- pliance with the NO waste as limits and low reducing agent loss (otherwise, separation and recirculation may possi%ly be necessary). 3. No formation of by-products (.. N2O). 4. Resistance of the active components and the catalyst carrier to sulphur and low SO2 oxida- tion and/or reduction activity on the part of the catalyst. The available results concernin the various precious metal catalyWreducing agent combina- tions showthat, when using -gee reducing agents, the high selectivityvalues targeted (Crite- rion were not reached in any case.The best selectivity values of 3Voare achieved according to the objective at temperatures below 2", but the desired high degree of NO and reduc- ing agent conversion (Criterion cannot then be realised. When using NH, as the reducing aaent, it must be assumed -as is k| Model Type | Helical speed reduction gearboxes H4 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 25500.000000 |

| Ratio Range | 1 : 125…450 |

| Low Speed Output | Hollow shaft with shrink disk |

| Nominal Torque | 27200 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | FLENDER TÜBINGEN GMBH |

| Country of Manufacture | Sweden |

| Data Sheet & Drawings | H4-DV8A lubricants only may be used You will find current Helical speed reduction gearboxes H4 |