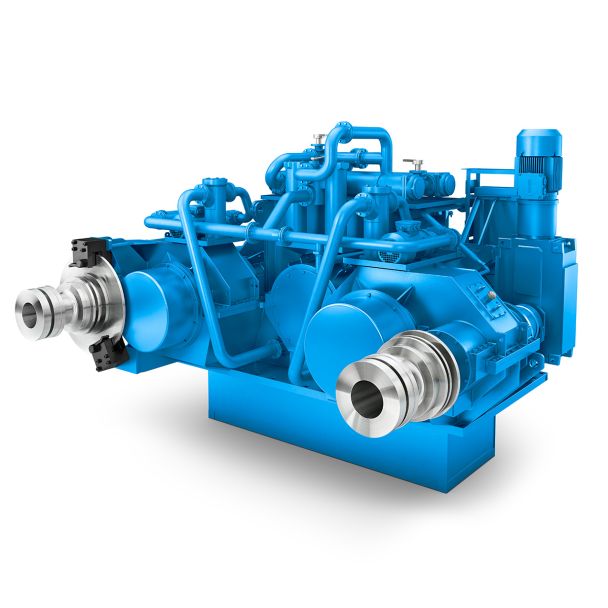

H3SV-27-C flender n bipex Helical speed reducer H3

In stock

SKU

H3SV-27-C

$486,428.57

Flender/Flender Gear Units/Helical speed reducer H3

cien cy and long life, it is essential that the lubricating oil be maintained at the correct level. The recommended grade of oil must be used at all times, since the us of unsuitable oil may result in excessive temperature

grade of oil must be used at all times, since the us of unsuitable oil may result in excessive temperature  rise, loss of efficiency and consequent damage to gears and bearings. The lubricating oil level should be checked at regular

rise, loss of efficiency and consequent damage to gears and bearings. The lubricating oil level should be checked at regular  intervals. We recommend that the first oil change should be carried our after approximately 5 hours initial operation and thereafter.

intervals. We recommend that the first oil change should be carried our after approximately 5 hours initial operation and thereafter.  Under normal operating condi tions the oil should be changed every 1,0 operating hours. If however, syn thetic lubricant is used, hen this period of time can be extended to 2,0 hours or alter natively four years maximum. In applications where arduous operating conditions exist, the ubricant should be changed at more frequent intervals. Grease packed bearings should be cleaned and re-greased every 1,0 hours, care being taken that onl approximately 4% of the fr ee volume of the bearing is filled with grease in order to avoid overheating of the bearing. Whenever the lubricating oil is changed it is preferable to dismantle and thoroughly clean the gear case, gear wheels and bearings. Afte dismantling, the component parts of the gear unit should be thoroughly cleaned with flus hing oil or cleaning benzine and all gear case joints should be cleaned to ensure that ll traces of the original sealing compound are removed. Any foreign matter and the cleaning fluid should be removed from the gear unit bearings and gear wheels. The bearings should be re-greased immediately after cleaning and drying. When re-assembling, all mating Bredgar Road, Gillingham, Kent, ME8 6PN Tel: 0 3 .Price: sales Siemens Flender mixertech.co.ukFax: 0 3 Internet: Germany mixertech.co.uk _______________________________________________________________________________ Surfaces of the gear case must be free from oil and grease and coated with an oil resistant

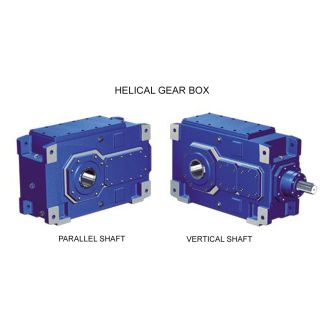

Under normal operating condi tions the oil should be changed every 1,0 operating hours. If however, syn thetic lubricant is used, hen this period of time can be extended to 2,0 hours or alter natively four years maximum. In applications where arduous operating conditions exist, the ubricant should be changed at more frequent intervals. Grease packed bearings should be cleaned and re-greased every 1,0 hours, care being taken that onl approximately 4% of the fr ee volume of the bearing is filled with grease in order to avoid overheating of the bearing. Whenever the lubricating oil is changed it is preferable to dismantle and thoroughly clean the gear case, gear wheels and bearings. Afte dismantling, the component parts of the gear unit should be thoroughly cleaned with flus hing oil or cleaning benzine and all gear case joints should be cleaned to ensure that ll traces of the original sealing compound are removed. Any foreign matter and the cleaning fluid should be removed from the gear unit bearings and gear wheels. The bearings should be re-greased immediately after cleaning and drying. When re-assembling, all mating Bredgar Road, Gillingham, Kent, ME8 6PN Tel: 0 3 .Price: sales Siemens Flender mixertech.co.ukFax: 0 3 Internet: Germany mixertech.co.uk _______________________________________________________________________________ Surfaces of the gear case must be free from oil and grease and coated with an oil resistant| Model Type | Helical speed reducer H3 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 22700.000000 |

| Ratio Range | 1 : 22.4…90 |

| Low Speed Output | Solid shaft with parallel key acc. to DIN 6885/1 |

| Nominal Torque | 1230000 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | A. Fried. Flender AG |

| Country of Manufacture | Germany |

| Data Sheet & Drawings | H3SV-27-C flender n bipex Helical speed reducer H3 |