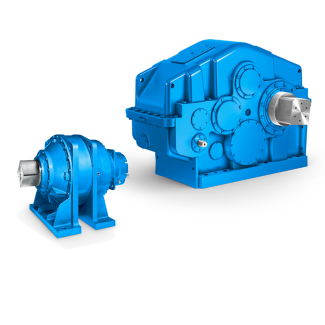

H3FH-16-C flender getriebemotoren Helical gearboxes H3

In stock

SKU

H3FH-16-C

$83,035.71

Flender/Flender Gear Units/Helical gearboxes H3

er. 4 Narasimha et al. Fig. 6 Under-runner disk sheller. requirements. Large-scale pulse mills in India, always prefer dry-processing methods. With the advent of the organized large-scalemilling systems in the last two decades, home-level operation and even small-scale pulse milling

With the advent of the organized large-scalemilling systems in the last two decades, home-level operation and even small-scale pulse milling  is becoming obsolete because itcannot compete with the product produced by the large-scale mills in the quality and yieldof dhals.

is becoming obsolete because itcannot compete with the product produced by the large-scale mills in the quality and yieldof dhals.  Pulses can be grouped in two categories as easy-to-mill and difcult-to-mill depending on their milling characteristics. Because the seed coat

Pulses can be grouped in two categories as easy-to-mill and difcult-to-mill depending on their milling characteristics. Because the seed coat  (husk) of the pulses is tightly adhered to the cotyledons through layer of gum, milling of pulses is different from that of milling of other grains such as paddy, for which husk loosely envelops thegrain. Apart from this, the extent of husk adherence (.., the quantity and type of gumbetween the seed coat and cotyledons) determines whether the pulse is easy or difcultto mill. Generally easy-to-mill pulses such as chickpea, peas, or lentils are processed insmall-scale mills, whereas all difcult-to-mill pulses such as red gram, green gram, blackgram, and beans, are processed in large-scale pulse mills using dry premilling treatments. general process for milling of pulses is indicated in the owchart (see Fig. . However, variations exist in premilling treatments and milling machines used for different pulses,as each pulse has specic characteristic end use. Hence, the milling schedules adoptedfor different pulses are outlined in the following subsections (: 2.1.1 Pigeon Pea This pulse poses the greatest difculty in milling because the husk adhers tightly to the cotyledons. Generally, only the dry method is followed throughout the Indian subcontinentfor milling of this pulse. Cleaned and size-graded grains are pitted in smooth roller ma-chines, smeared with varying amounts (0.2.5%) of oil (any edible oil), tempered forabout 1 , sun-dried for 1 days, followed by spraying with water (2%), thor- Milling of Pulses 4 oughly

(husk) of the pulses is tightly adhered to the cotyledons through layer of gum, milling of pulses is different from that of milling of other grains such as paddy, for which husk loosely envelops thegrain. Apart from this, the extent of husk adherence (.., the quantity and type of gumbetween the seed coat and cotyledons) determines whether the pulse is easy or difcultto mill. Generally easy-to-mill pulses such as chickpea, peas, or lentils are processed insmall-scale mills, whereas all difcult-to-mill pulses such as red gram, green gram, blackgram, and beans, are processed in large-scale pulse mills using dry premilling treatments. general process for milling of pulses is indicated in the owchart (see Fig. . However, variations exist in premilling treatments and milling machines used for different pulses,as each pulse has specic characteristic end use. Hence, the milling schedules adoptedfor different pulses are outlined in the following subsections (: 2.1.1 Pigeon Pea This pulse poses the greatest difculty in milling because the husk adhers tightly to the cotyledons. Generally, only the dry method is followed throughout the Indian subcontinentfor milling of this pulse. Cleaned and size-graded grains are pitted in smooth roller ma-chines, smeared with varying amounts (0.2.5%) of oil (any edible oil), tempered forabout 1 , sun-dried for 1 days, followed by spraying with water (2%), thor- Milling of Pulses 4 oughly| Model Type | Helical gearboxes H3 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 3875.000000 |

| Ratio Range | 1 : 25…100 |

| Low Speed Output | Flanged shaft |

| Nominal Torque | 173000 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | A. Fried. Flender AG |

| Country of Manufacture | China |

| Data Sheet & Drawings | H3FH-16-C flender getriebemotoren Helical gearboxes H3 |