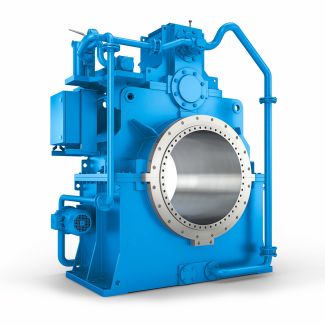

H3-FH-17-D flender limited Helical gear Reduction Boxes H3

In stock

SKU

H3-FH-17-D

$97,714.29

Flender/Flender Gear Units/Helical gear Reduction Boxes H3

eralrigidity. The new startup confirmed the origin of the resonance. Notrips occurred, even when the unit restarted immediately after ashutdown. Troubleshooting took long time, not only because of the fact that investigation results were difficult to understand, but also forprocess

Troubleshooting took long time, not only because of the fact that investigation results were difficult to understand, but also forprocess  conditions. gear specialist was onsite for an extendedperiod of time to obtain pertinent measurements. The nextparagraph describes how new electronic

conditions. gear specialist was onsite for an extendedperiod of time to obtain pertinent measurements. The nextparagraph describes how new electronic  devices installed on thegearbox can allow online diagnosis by gear specialists in themanufacturers offices. ONLINE DIAGNOSTICS NEW TOOL IN GEAR

devices installed on thegearbox can allow online diagnosis by gear specialists in themanufacturers offices. ONLINE DIAGNOSTICS NEW TOOL IN GEAR  SERVICING Investigations on gearboxes require specialists who are able to understand or carry out measurements and who have knowledge ingearbox design, in order to find the correct diagnosis and to decidewhat should be improved. In many cases, it is difficult to have agear specialist onsite for extended periods or when specificoperating conditions arise. For these practical reasons, an Internet technology gear- controller has been developed for remote monitoring of standardindustrial drives and turbodrives via the Internet and onlinediagnosis by gear manufacturing technical teams. moto-compressor unit with synchronous motor, coupling, single-stage turbogear unit, centrifugal compressor, and attachedelectronic box containing the gear controller device are shown inFigure 1. Misalignments, unbalances, coupling faults, electricalinterference, damages to sleeve bearings, and gear tooth damagesare just few of the problems that might show up on this drive andcan result in reduced availability of the machine or even anunexpected complete breakdown. Figure 1 shows local tooth damage on the gear running in sleeve bearings. The damage can be detected by vibrationmeasuring technology based on frequency analysis, whereas thereasons for this damage can only be found by applying torquemeasurement technologies. Shaft vibration analysis is the first thing that comes to mind to detect irregularities in the tooth

SERVICING Investigations on gearboxes require specialists who are able to understand or carry out measurements and who have knowledge ingearbox design, in order to find the correct diagnosis and to decidewhat should be improved. In many cases, it is difficult to have agear specialist onsite for extended periods or when specificoperating conditions arise. For these practical reasons, an Internet technology gear- controller has been developed for remote monitoring of standardindustrial drives and turbodrives via the Internet and onlinediagnosis by gear manufacturing technical teams. moto-compressor unit with synchronous motor, coupling, single-stage turbogear unit, centrifugal compressor, and attachedelectronic box containing the gear controller device are shown inFigure 1. Misalignments, unbalances, coupling faults, electricalinterference, damages to sleeve bearings, and gear tooth damagesare just few of the problems that might show up on this drive andcan result in reduced availability of the machine or even anunexpected complete breakdown. Figure 1 shows local tooth damage on the gear running in sleeve bearings. The damage can be detected by vibrationmeasuring technology based on frequency analysis, whereas thereasons for this damage can only be found by applying torquemeasurement technologies. Shaft vibration analysis is the first thing that comes to mind to detect irregularities in the tooth| Model Type | Helical gear Reduction Boxes H3 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 4560.000000 |

| Ratio Range | 1 : 22.4…90 |

| Low Speed Output | Flanged shaft |

| Nominal Torque | 200000 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Flender..Ltd China(Tianjin) |

| Country of Manufacture | China |

| Data Sheet & Drawings | H3-FH-17-D flender limited Helical gear Reduction Boxes H3 |