Flender/Flender Gear Units/Helical gearbox H3

consumer is generator, it can be reversed to act as an electric starter-motor to start the turbine. Because of the high rotation speeds and relatively low torques involved, these bevel gears are subject to quite different demands than those used

high rotation speeds and relatively low torques involved, these bevel gears are subject to quite different demands than those used  for example in automotive axle gear drives. Fig. 1.5 Gas turbine with bevel gear trains1.3 Aircraft Engines 5 1.3.2 Helicopter

for example in automotive axle gear drives. Fig. 1.5 Gas turbine with bevel gear trains1.3 Aircraft Engines 5 1.3.2 Helicopter  Gears Similarly to airplanes, helicopter engines are usually gas turbines and deliver the power used to drive the main and

Gears Similarly to airplanes, helicopter engines are usually gas turbines and deliver the power used to drive the main and  tail rotors while the residual exhaust jet supple- ments propulsion during ight. Because the shaft of gas turbines is invariably mounted horizontally, an angular gear train is needed to power the main rotor. The counter torque generated by the main rotor around the vertical axis of the helicopter is compensated by means of tail rotor (Fig. 1.. The rotational speed of the main rotor is always chosen such that blade tip velocity at maximum forward ight speed is subsonic. Depending on the diameter of the rotor, this results in rotor speeds below 5 RPM. Typical power turbine shaft speeds being above 8,0 RPM, and thus signicantly higher than that of the rotor, reduction gearbox with large transmission ratio is required. Planetary gears are ideal for such applications: the bevel gears are placed ahead of the input stage to the planetary gear train such that the gear designer is dealing with higher rotational speeds rather than higher torques. Other bevel gear sets are necessary to drive the tail rotor. If continuous shaft runs from the main gear unit to the tail rotor, one bevel gear set is required such that the longitudinal shaft can drive the tail rotor mounted at right angle. When it is not possible to install continuous shaft (Fig. 1., number of shaft sections are required. Further bevel gear sets are then needed to transmit rotation to each of the sections of the tail rotor drive. 1.3.3 Flap Drives on Aircraft Wings Apart from rapidly rotating bevel gears in aircraft

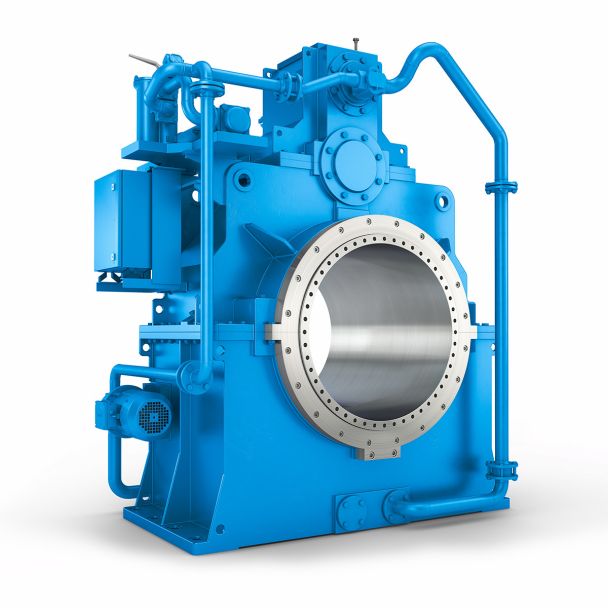

tail rotors while the residual exhaust jet supple- ments propulsion during ight. Because the shaft of gas turbines is invariably mounted horizontally, an angular gear train is needed to power the main rotor. The counter torque generated by the main rotor around the vertical axis of the helicopter is compensated by means of tail rotor (Fig. 1.. The rotational speed of the main rotor is always chosen such that blade tip velocity at maximum forward ight speed is subsonic. Depending on the diameter of the rotor, this results in rotor speeds below 5 RPM. Typical power turbine shaft speeds being above 8,0 RPM, and thus signicantly higher than that of the rotor, reduction gearbox with large transmission ratio is required. Planetary gears are ideal for such applications: the bevel gears are placed ahead of the input stage to the planetary gear train such that the gear designer is dealing with higher rotational speeds rather than higher torques. Other bevel gear sets are necessary to drive the tail rotor. If continuous shaft runs from the main gear unit to the tail rotor, one bevel gear set is required such that the longitudinal shaft can drive the tail rotor mounted at right angle. When it is not possible to install continuous shaft (Fig. 1., number of shaft sections are required. Further bevel gear sets are then needed to transmit rotation to each of the sections of the tail rotor drive. 1.3.3 Flap Drives on Aircraft Wings Apart from rapidly rotating bevel gears in aircraft| Model Type | Helical gearbox H3 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 22700.000000 |

| Ratio Range | 1 : 22.4…90 |

| Low Speed Output | Solid shaft with parallel key acc. to DIN 6885/1 with reinforced spigot |

| Nominal Torque | 1230000 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Flender GmbH |

| Country of Manufacture | Monaco |

| Data Sheet & Drawings | H3-VH27-B flender 175823 Helical gearbox H3 |