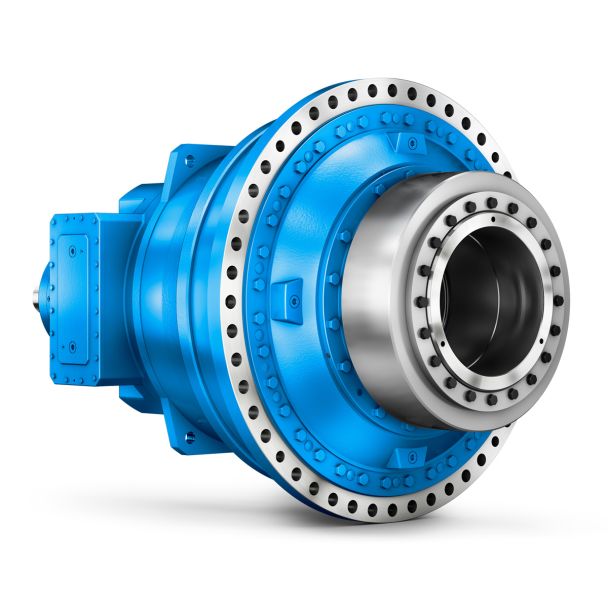

H3-VH-5-D flender motox Helical gear Reduction Boxes H3

In stock

SKU

H3-VH-5-D

$6,857.14

Flender/Flender Gear Units/Helical gear Reduction Boxes H3

circuit. The microwave-heating system is quite different from RF-heating systems; how-ever, it consists of high-frequency power source (magnetron), power transmissionmedium, tuning system, and an applicator. Dielectric drying relies on the principle that energy is absorbed by the water present in

tuning system, and an applicator. Dielectric drying relies on the principle that energy is absorbed by the water present in  the material undergoing drying. The absorbed energy causes the temperature to rise,evaporates water vapor, and reduces the moisture level. Calculation

the material undergoing drying. The absorbed energy causes the temperature to rise,evaporates water vapor, and reduces the moisture level. Calculation  of the actual amountof energy (or power) absorbed by dielectric body is essential for full understandingof the drying process by

of the actual amountof energy (or power) absorbed by dielectric body is essential for full understandingof the drying process by  the use of radio frequency and microwave energy. The amount Grain-Drying Systems 1 of microwave energy dissipated as heat in determined volume of material can be ex- pressed ( by Eq. (. /H1 lE2 loc ( where Pis microwave power dissipated as heat (), Vis the volume of material (m, is the frequency of the electromagnetic eld (Hz), lis the loss factor of the material, and Elocis the local electric eld strength within the material (/). In the drying context, for which the moisture is removed continuously, the dielectric loss decreases and, consequently, the magnitude of heating reduces. It is interesting that in some materials, this decrease in loss factor is so critical that below certain moisture content (critical moisture content), they apparently become transparent to this spectrumof electromagnetic radiation. For highly hygroscopic materials, this occurs between 1and 4% db (. Unlike removal of moisture in conventional drying with hot air, the drying by dielec- tric and microwave systems is quite fast because of rapid generation of vapor within thematerial, and the total pressure gradient thus established controls the drying process. Al- though the systems can moderate the drying rate, rapid heating may lead to scorching or burning of the products. In some cases, the hindrance to escape of the generated steaminside may cause rupture of the material into pieces or even an explosion.

the use of radio frequency and microwave energy. The amount Grain-Drying Systems 1 of microwave energy dissipated as heat in determined volume of material can be ex- pressed ( by Eq. (. /H1 lE2 loc ( where Pis microwave power dissipated as heat (), Vis the volume of material (m, is the frequency of the electromagnetic eld (Hz), lis the loss factor of the material, and Elocis the local electric eld strength within the material (/). In the drying context, for which the moisture is removed continuously, the dielectric loss decreases and, consequently, the magnitude of heating reduces. It is interesting that in some materials, this decrease in loss factor is so critical that below certain moisture content (critical moisture content), they apparently become transparent to this spectrumof electromagnetic radiation. For highly hygroscopic materials, this occurs between 1and 4% db (. Unlike removal of moisture in conventional drying with hot air, the drying by dielec- tric and microwave systems is quite fast because of rapid generation of vapor within thematerial, and the total pressure gradient thus established controls the drying process. Al- though the systems can moderate the drying rate, rapid heating may lead to scorching or burning of the products. In some cases, the hindrance to escape of the generated steaminside may cause rupture of the material into pieces or even an explosion.| Model Type | Helical gear Reduction Boxes H3 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 320.000000 |

| Ratio Range | 1 : 25…90 |

| Low Speed Output | Solid shaft with parallel key acc. to DIN 6885/1 with reinforced spigot |

| Nominal Torque | – Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | FLENDER ZAHNRADGETRIEBE |

| Country of Manufacture | Australia |

| Data Sheet & Drawings | H3-VH-5-D flender motox Helical gear Reduction Boxes H3 |