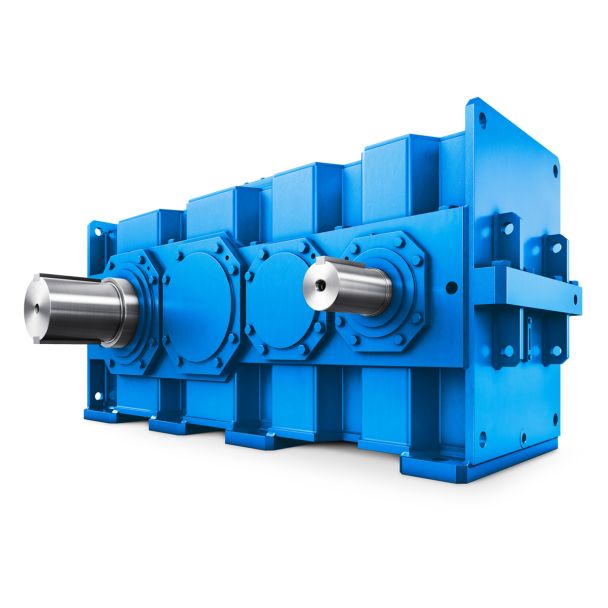

Flender/Flender Gear Units/Helical gear box H3

city needs. With the commissioning of the new sludge hand ling and treatment facility, the City of Tshwane could benefit from reassessing the capacity of the plant using advanced process modelling taking into account the impact of primary sludge not

from reassessing the capacity of the plant using advanced process modelling taking into account the impact of primary sludge not  being discharged to the balancing tanks. Ease of Plant Operation Implementing aeration ECMs through this approach results in simplified plant

being discharged to the balancing tanks. Ease of Plant Operation Implementing aeration ECMs through this approach results in simplified plant  operation for operations staff who because of the data intens ive nature of this approach, had to be closely involved

operation for operations staff who because of the data intens ive nature of this approach, had to be closely involved  with the project and responsible for data coll ection and physical process audits. This together with access to the knowledge dissemination workshop enhanced the staff` knowledge about the plant. In addition implementing advanced process co ntrol strategies increases automa tion which further simplifies the overall operation and control of the plant. 4.7.6 Summary Zeekoegat WWTP is sophisticated EBPR activated sludge plant. The bioreactor has been optimally designed with flexible process configurations to enable compliance with the strict final effluent and license limits under varying influent flows, loads, in fluent quality and operating conditions. The plant has also been designed to minimise aeration energy use with highly efficient fine bubble diffused aeration system consisting of latest model membrane diffusers in both modules, single speed centrifugal blowers for Module 1 and the latest high speed turbo blowers for Module 2. Influent flow is also balanced after primary clarification and constant flow is drawn from the balancing tanks to the bioreactor, effectively eliminating large diurnal load variations and minimising peak energy demand. To 4-3 minimise aeration energy use further, the chief Oper ator developed special aeration control algorithm which is more efficient than the contractor installed traditional fixed DO control strategy. In terms of compliance with the DWS final efflue nt discharge license requireme

with the project and responsible for data coll ection and physical process audits. This together with access to the knowledge dissemination workshop enhanced the staff` knowledge about the plant. In addition implementing advanced process co ntrol strategies increases automa tion which further simplifies the overall operation and control of the plant. 4.7.6 Summary Zeekoegat WWTP is sophisticated EBPR activated sludge plant. The bioreactor has been optimally designed with flexible process configurations to enable compliance with the strict final effluent and license limits under varying influent flows, loads, in fluent quality and operating conditions. The plant has also been designed to minimise aeration energy use with highly efficient fine bubble diffused aeration system consisting of latest model membrane diffusers in both modules, single speed centrifugal blowers for Module 1 and the latest high speed turbo blowers for Module 2. Influent flow is also balanced after primary clarification and constant flow is drawn from the balancing tanks to the bioreactor, effectively eliminating large diurnal load variations and minimising peak energy demand. To 4-3 minimise aeration energy use further, the chief Oper ator developed special aeration control algorithm which is more efficient than the contractor installed traditional fixed DO control strategy. In terms of compliance with the DWS final efflue nt discharge license requireme| Model Type | Helical gear box H3 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 365.000000 |

| Ratio Range | 1 : 31.5…112 |

| Low Speed Output | Solid shaft with parallel key acc. to DIN 6885/1 with reinforced spigot |

| Nominal Torque | – Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | A. Friedr. Flender GmbH |

| Country of Manufacture | Bahamas |

| Data Sheet & Drawings | H3VH-6-C flender getriebemotor Helical gear box H3 |