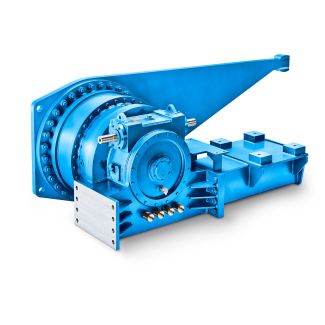

H3-FV-18B flender gear unit Helical gear Reduction Boxes H3

In stock

SKU

H3-FV-18B

$107,785.71

Flender/Flender Gear Units/Helical gear Reduction Boxes H3

esh. Practical limitations arise mainly from the available spacearound the gears or from application of the load [ FVA3 ].4.4 Stress Analysis 1 Using strain gauges to measure tooth root stress Stresses in the tooth root zone of gear teeth

Stress Analysis 1 Using strain gauges to measure tooth root stress Stresses in the tooth root zone of gear teeth  can be derived from the measurement of deformations in the llet.Depending on the stress condition, the actual stress can be

can be derived from the measurement of deformations in the llet.Depending on the stress condition, the actual stress can be  calculated using the modulus of elasticity. Deformation measurements are made using strain gauges. More exact results are obtained with chain

calculated using the modulus of elasticity. Deformation measurements are made using strain gauges. More exact results are obtained with chain  consisting of number of individualstrain gauges placed consecutively along the tooth face width. The measurementprinciple lies in evaluating the change in electrical resistance of the strain gaugesunder deformation. The strain gauges are glued at the bottom of tooth in the lletarea where the highest stress, and thus deformation, is expected (the middle of eachstrain gauge is around the 3 /C1tangent in the llet). series of measurement results is obtained using the chain of strain gauges which results in stress distribution curve compensating for any inaccuracy in strain gauge positioning from affecting the maximum stress value which is being sought. The advantage of this method isthat the direct measurement of tooth root stress detects load differences along theface width even when conventional contact pattern test shows pattern extendingalmost evenly across the entire tooth face width. disadvantage in terms ofwidespread use lies in the substantial preparation for the test usually required atthe design stage. The method is therefore generally reserved for large gear sets, orfor specialized tests [ BECK9 ,BAUM9 ,KUNE9 ]. Thermography The power loss which occurs due to pressure and sliding when two tooth anks mesh leads to local heating of the anks. Recording the resultingthermograph provides representation of the tooth ank contact stresses. Becauseof the good thermal conductivity of the gears, the accuracy of the information obtained in this way depends on the bre

consisting of number of individualstrain gauges placed consecutively along the tooth face width. The measurementprinciple lies in evaluating the change in electrical resistance of the strain gaugesunder deformation. The strain gauges are glued at the bottom of tooth in the lletarea where the highest stress, and thus deformation, is expected (the middle of eachstrain gauge is around the 3 /C1tangent in the llet). series of measurement results is obtained using the chain of strain gauges which results in stress distribution curve compensating for any inaccuracy in strain gauge positioning from affecting the maximum stress value which is being sought. The advantage of this method isthat the direct measurement of tooth root stress detects load differences along theface width even when conventional contact pattern test shows pattern extendingalmost evenly across the entire tooth face width. disadvantage in terms ofwidespread use lies in the substantial preparation for the test usually required atthe design stage. The method is therefore generally reserved for large gear sets, orfor specialized tests [ BECK9 ,BAUM9 ,KUNE9 ]. Thermography The power loss which occurs due to pressure and sliding when two tooth anks mesh leads to local heating of the anks. Recording the resultingthermograph provides representation of the tooth ank contact stresses. Becauseof the good thermal conductivity of the gears, the accuracy of the information obtained in this way depends on the bre| Model Type | Helical gear Reduction Boxes H3 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 5030.000000 |

| Ratio Range | 1 : 25…100 |

| Low Speed Output | Flanged shaft |

| Nominal Torque | 240000 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | FLENOER-GRAFFENSTA |

| Country of Manufacture | Germany |

| Data Sheet & Drawings | H3-FV-18B flender gear unit Helical gear Reduction Boxes H3 |