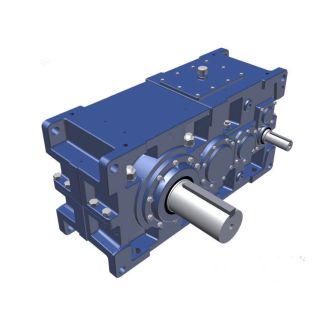

Flender/Flender Gear Units/Helical gear boxes H3

Eq. (, /m2 absolute temperature of the air, ta temperature of air at the dryer inlet in Eq. (, ; ambient temperature in Eq. (, te temperature of air at the dryer outlet, tg temperature of air leaving the grain,

ambient temperature in Eq. (, te temperature of air at the dryer outlet, tg temperature of air leaving the grain,  ti air temperature at the collector inlet in Eq. (, to air temperature at the collector outlet in Eq. (,

ti air temperature at the collector inlet in Eq. (, to air temperature at the collector outlet in Eq. (,  UL overall heat transfer coefcient in Eq. (, /m2K/H1 volume of material receiving microwave energy in Eq. (, m3 Ve

UL overall heat transfer coefcient in Eq. (, /m2K/H1 volume of material receiving microwave energy in Eq. (, m3 Ve  terminal velocity of particle in Eq. (, / Vf minimum uidization velocity in Eq. (, / Vs minimum supercial uid velocity in Eq. (, / specic volume of air, m3/kg Wd dry matter in grain, kg mass ow rate of air, kg/ xf nal moisture content of the grain in Eq. (, decimal, dry basis x0 initial moisture content of grain in Eq. (, decimal, dry basis Greek Symbols cross-sectional area of the dryer in Eq. (, m2 frequency of electromagnetic eld in Eq. (, Hz thermal efciency of solar air-heating system, dimensionless loss factor of material receiving microwave energy in Eq. (, dimen- sionless void fraction of grain bed, dimensionless drying time, drying time for maximum rate period in Eq. [4], drying time for falling rate period in Eq. [5], viscosity of air, kg/ms/H1 density of air, kg/m3 density of solid particle, kg/m3 spehericity of solid particle, dimensionless ()eeffective transmittanceabsorptance product in Eq. (, dimensionless Grain-Drying Systems 1 REFERENCES 1. AS Mujumdar, AS Menon. Drying of solids: principles, classication and selection of dryers. In: AS Mujumdar, ed. Handbook of Industrial Drying. Vol. 1. 2nd ed. New York: MarcelDekker, 1, pp. 1. 2. Chakraverty. Post Harvest Technology of Cereals, Pulses and Oilseeds, 3rd. ed., New Delhi: Oxford & IBH Publishing, 1. 3. CGJ Baker. The design of ights in cascade rotary dryers. Drying Technol 6:6, 1.4. NGC Ienger, Bhaskar, Dharmarajan. Studies on sand parboiling and drying of paddy. Agric Eng 8:5, 1. 5. MV Ramakumar, GSV Raghavan, Javar

terminal velocity of particle in Eq. (, / Vf minimum uidization velocity in Eq. (, / Vs minimum supercial uid velocity in Eq. (, / specic volume of air, m3/kg Wd dry matter in grain, kg mass ow rate of air, kg/ xf nal moisture content of the grain in Eq. (, decimal, dry basis x0 initial moisture content of grain in Eq. (, decimal, dry basis Greek Symbols cross-sectional area of the dryer in Eq. (, m2 frequency of electromagnetic eld in Eq. (, Hz thermal efciency of solar air-heating system, dimensionless loss factor of material receiving microwave energy in Eq. (, dimen- sionless void fraction of grain bed, dimensionless drying time, drying time for maximum rate period in Eq. [4], drying time for falling rate period in Eq. [5], viscosity of air, kg/ms/H1 density of air, kg/m3 density of solid particle, kg/m3 spehericity of solid particle, dimensionless ()eeffective transmittanceabsorptance product in Eq. (, dimensionless Grain-Drying Systems 1 REFERENCES 1. AS Mujumdar, AS Menon. Drying of solids: principles, classication and selection of dryers. In: AS Mujumdar, ed. Handbook of Industrial Drying. Vol. 1. 2nd ed. New York: MarcelDekker, 1, pp. 1. 2. Chakraverty. Post Harvest Technology of Cereals, Pulses and Oilseeds, 3rd. ed., New Delhi: Oxford & IBH Publishing, 1. 3. CGJ Baker. The design of ights in cascade rotary dryers. Drying Technol 6:6, 1.4. NGC Ienger, Bhaskar, Dharmarajan. Studies on sand parboiling and drying of paddy. Agric Eng 8:5, 1. 5. MV Ramakumar, GSV Raghavan, Javar| Model Type | Helical gear boxes H3 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 365.000000 |

| Ratio Range | 1 : 31.5…112 |

| Low Speed Output | Flanged shaft |

| Nominal Torque | – Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Flender..Ltd China(Tianjin) |

| Country of Manufacture | Tunisia |

| Data Sheet & Drawings | H3-FH-6B eupex coupling Helical gear boxes H3 |