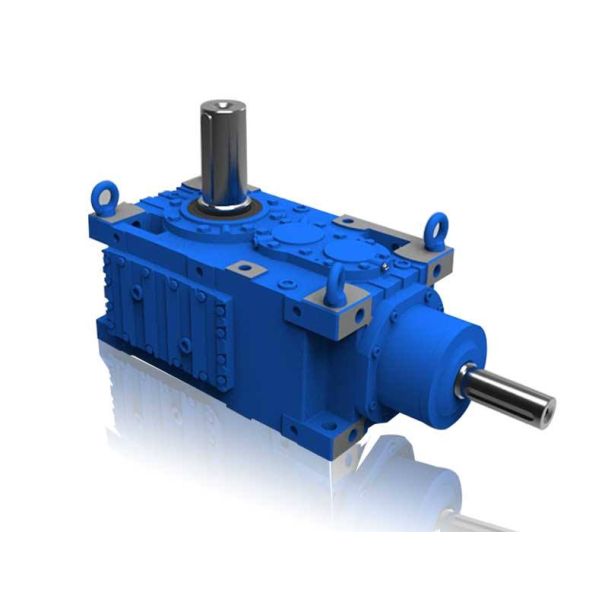

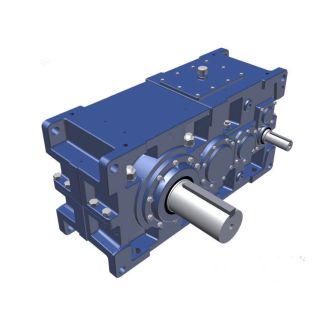

Flender/Flender Gear Units/Helical gear units H3

epicycloid occurs when the radius on which the cutting edges are positioned is greater than that of the rolling circle. Fig. 2.4 Single indexing and continuous indexing methods1 2 Fundamentals of Bevel Gears When manufacturing generated spiral bevel gear, curved

Fig. 2.4 Single indexing and continuous indexing methods1 2 Fundamentals of Bevel Gears When manufacturing generated spiral bevel gear, curved  tooth prole is created on both the pinion and wheel by generating motion. An alternate methodis to only generate the

tooth prole is created on both the pinion and wheel by generating motion. An alternate methodis to only generate the  pinion and form cut the tooth spaces on the wheel by simple plunge cut process, which is known as non-generated

pinion and form cut the tooth spaces on the wheel by simple plunge cut process, which is known as non-generated  method or FORMATE . The process saves time in machining the wheel, and can be used for transmission ratios of about 2.5 and above. Since there is no generating motion when cutting thewheel, the tool prole is reproduced exactly in the tooth slot. The associated pinionis produced in modied generating process (see Sect. 3.2.1 ) to ensure that it meshes properly with the wheel. Spiral bevel gear tooth geometry depends on the manufacturing method employed, not only in terms of the classication criteria noted above, but also with respect to the nal tooth ank and root topography. For example, it is impossible to pair pinion produced with the Zyklo-Palloid method to wheel manufactured with the Spiroex method, although both are made with face hobbing process and matchin terms of their macro geometry (.. normal module and elongated epicycloid). Zyklo-Palloid This is continuous indexing method in which both bevel gears, the pinion and wheel, are always generated. Tooth depth is constant and the toothtrace is an elongated epicycloid. The special feature of this method is the use of atwo-part cutter head (see Fig. 6. where one of the two interleaved parts of the cutter head holds inner blades cutting the convex tooth anks, and the other partholds outer blades for the concave tooth anks. Prole crowning is achieved by aspherical blade prole (cutter blade prole modication) while lengthwisecrowning is obtained by difference in radius between the inner and outer blades. The two-part cutt

method or FORMATE . The process saves time in machining the wheel, and can be used for transmission ratios of about 2.5 and above. Since there is no generating motion when cutting thewheel, the tool prole is reproduced exactly in the tooth slot. The associated pinionis produced in modied generating process (see Sect. 3.2.1 ) to ensure that it meshes properly with the wheel. Spiral bevel gear tooth geometry depends on the manufacturing method employed, not only in terms of the classication criteria noted above, but also with respect to the nal tooth ank and root topography. For example, it is impossible to pair pinion produced with the Zyklo-Palloid method to wheel manufactured with the Spiroex method, although both are made with face hobbing process and matchin terms of their macro geometry (.. normal module and elongated epicycloid). Zyklo-Palloid This is continuous indexing method in which both bevel gears, the pinion and wheel, are always generated. Tooth depth is constant and the toothtrace is an elongated epicycloid. The special feature of this method is the use of atwo-part cutter head (see Fig. 6. where one of the two interleaved parts of the cutter head holds inner blades cutting the convex tooth anks, and the other partholds outer blades for the concave tooth anks. Prole crowning is achieved by aspherical blade prole (cutter blade prole modication) while lengthwisecrowning is obtained by difference in radius between the inner and outer blades. The two-part cutt| Model Type | Helical gear units H3 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 320.000000 |

| Ratio Range | 1 : 25…90 |

| Low Speed Output | Flanged shaft |

| Nominal Torque | – Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Flender GmbH |

| Country of Manufacture | Tonga |

| Data Sheet & Drawings | H3-FH-5-D flender rotterdam Helical gear units H3 |