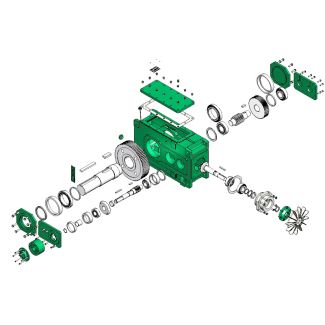

flender kupplung H3-DH-13-D Helical speed reduction gearbox H3

In stock

SKU

H3-DH-13-D

$49,178.57

Flender/Flender Gear Units/Helical speed reduction gearbox H3

e the flame and the temperature profile of the rotary kiln and require permanent adjustment of the burner to achieve constant product quality and low pollutant emissions with dif-ferent fuel inputs. This requires mod- ern burner control system. Another option

constant product quality and low pollutant emissions with dif-ferent fuel inputs. This requires mod- ern burner control system. Another option  to improve energy balance and reduce the carbon foot- print is the production of cements with lower contents of cement

to improve energy balance and reduce the carbon foot- print is the production of cements with lower contents of cement  clinker, because the calcination of the clinker in particular consumes great amount of energy. The substitutes used are in -

clinker, because the calcination of the clinker in particular consumes great amount of energy. The substitutes used are in -  dustrial by-products such as slag sand and fly ash. Although the energy bal - ance of these substitutes is better, they cannot be added in just any amount, as this would significantly impair the quality of the cement. Hence, intelli-gent measuring methods and profes-sional field devices are absolutely nec- essary for the apportioning of these substitute substances and the subse-quent homogenization processes. In recent years, research has focused more and more on the use of alterna- tive binding agents with lower require- ments of lime and energy. Apart from so-called belite cements, geopolymers and sulphoaluminate cements, Celite- ment is to be mentioned here, which is based on hitherto unknown calcium hy - drosilicates. The future will show which approaches can provide sustained improvement of the energy balance and the carbon footprint of cement. Success factor: process stability Aside from capital-intensive measures such as the installation of heat recov - ery systems and new motors, the use of refuse-derived fuels or the develop- ment of new binding agents, one as-pect should not be forgotten when we consider energy optimization, namely maintaining stable and trouble-free production process. To enable cement works to produce cement around the clock, all sub-processes from crush- ing the limestone to calcination of the clinker, all the way to storing the fin-ished cement in silos need to func-tion without fault and interact perfect- ly. Up-

dustrial by-products such as slag sand and fly ash. Although the energy bal - ance of these substitutes is better, they cannot be added in just any amount, as this would significantly impair the quality of the cement. Hence, intelli-gent measuring methods and profes-sional field devices are absolutely nec- essary for the apportioning of these substitute substances and the subse-quent homogenization processes. In recent years, research has focused more and more on the use of alterna- tive binding agents with lower require- ments of lime and energy. Apart from so-called belite cements, geopolymers and sulphoaluminate cements, Celite- ment is to be mentioned here, which is based on hitherto unknown calcium hy - drosilicates. The future will show which approaches can provide sustained improvement of the energy balance and the carbon footprint of cement. Success factor: process stability Aside from capital-intensive measures such as the installation of heat recov - ery systems and new motors, the use of refuse-derived fuels or the develop- ment of new binding agents, one as-pect should not be forgotten when we consider energy optimization, namely maintaining stable and trouble-free production process. To enable cement works to produce cement around the clock, all sub-processes from crush- ing the limestone to calcination of the clinker, all the way to storing the fin-ished cement in silos need to func-tion without fault and interact perfect- ly. Up-| Model Type | Helical speed reduction gearbox H3 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 2295.000000 |

| Ratio Range | 1 : 22.4…90 |

| Low Speed Output | Hollow shaft with shrink disk |

| Nominal Torque | 90700 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Siemens Flender |

| Country of Manufacture | Russia |

| Data Sheet & Drawings | flender kupplung H3-DH-13-D Helical speed reduction gearbox H3 |