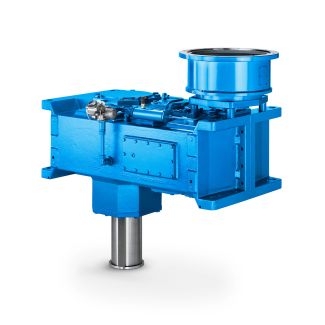

Helical gear Reduction Boxes H3 flender corporation H3-CV-28B

In stock

SKU

H3-CV-28B

$546,428.57

Flender/Flender Gear Units/Helical gear Reduction Boxes H3

dipping treatments are () soda dip: 0.2% to 0.3% NaOH at 9 for 2 , followed by water rinse; () Australian-type mix dip: 0.3% NaOH/H1.5% 2CO 3/H1.4% olive oil at 8 for 2 without rinsing; () Australian cold dip: 5%

Australian-type mix dip: 0.3% NaOH/H1.5% 2CO 3/H1.4% olive oil at 8 for 2 without rinsing; () Australian cold dip: 5%  2CO 3emulsied with 0.4% olive oil for 1 min at 3 C3C; () Califor- nia soda-oil dip: 0.4% solution of

2CO 3emulsied with 0.4% olive oil for 1 min at 3 C3C; () Califor- nia soda-oil dip: 0.4% solution of  soda ash and Na 2CO 3(Wyandotte powder) for 3 at 3C3C. Pretreatment techniques are applied with different solutions, temperatures, and

soda ash and Na 2CO 3(Wyandotte powder) for 3 at 3C3C. Pretreatment techniques are applied with different solutions, temperatures, and  dipping times. The sun drying process normally takes 2 weeks and produces dark raisinsif no sulfur pretreatment is applied. Articial air drying of grapes is also applied, but only to limited extent. The process starts with dipping of grapes in 0.2% hot lye, washing, spreading on trays, and sulfuring(exposing to burning sulfur). An average 1.8.3 kg of sulfur per metric ton of fresh fruitsis burned in sulfur house for about 4 . tunnel dryer is typically used for the grapedrying up to 9%1% .., the process takes 2 (. The sulfur dioxide concentra-tion of the nal product (Golden variety, bleached raisins) ranges between 1 and 2 ppm. small amount of grapes is puffed in vacuum shelf dryers, giving high- quality, low-density porous material of less than 4% moisture, which is used as an ingredi-ent of instant cereals, soups, desserts, cakes, etc. Additional information about raisin pro-duction can be found (. Some new techniques, employing, for example, microwaveenergy, have also been developed (. 6 Grabowski et al. 4.1.2 Pome Fruits (Apple and Pear) 4.1.2.1 Apple Apples are often preserved by drying on large scale. The largest quantities of apples are dried in the United States; signicant, but smaller, quantities are also dried in Canada, Australia, the Republic of South Africa, and Italy. Only articial dryers are used by com- mercial apple drying plants. For drying, the peeled and sliced apples are typically treatedwith weak solution of citric acid and potassium meta/bisulte dip. The latter providesSO 2in solutio

dipping times. The sun drying process normally takes 2 weeks and produces dark raisinsif no sulfur pretreatment is applied. Articial air drying of grapes is also applied, but only to limited extent. The process starts with dipping of grapes in 0.2% hot lye, washing, spreading on trays, and sulfuring(exposing to burning sulfur). An average 1.8.3 kg of sulfur per metric ton of fresh fruitsis burned in sulfur house for about 4 . tunnel dryer is typically used for the grapedrying up to 9%1% .., the process takes 2 (. The sulfur dioxide concentra-tion of the nal product (Golden variety, bleached raisins) ranges between 1 and 2 ppm. small amount of grapes is puffed in vacuum shelf dryers, giving high- quality, low-density porous material of less than 4% moisture, which is used as an ingredi-ent of instant cereals, soups, desserts, cakes, etc. Additional information about raisin pro-duction can be found (. Some new techniques, employing, for example, microwaveenergy, have also been developed (. 6 Grabowski et al. 4.1.2 Pome Fruits (Apple and Pear) 4.1.2.1 Apple Apples are often preserved by drying on large scale. The largest quantities of apples are dried in the United States; signicant, but smaller, quantities are also dried in Canada, Australia, the Republic of South Africa, and Italy. Only articial dryers are used by com- mercial apple drying plants. For drying, the peeled and sliced apples are typically treatedwith weak solution of citric acid and potassium meta/bisulte dip. The latter providesSO 2in solutio| Model Type | Helical gear Reduction Boxes H3 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 25500.000000 |

| Ratio Range | 1 : 25…100 |

| Low Speed Output | Solid shaft without parallel key |

| Nominal Torque | 1400000 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | Siemens Flender |

| Country of Manufacture | Grenada |

| Data Sheet & Drawings | Helical gear Reduction Boxes H3 flender corporation H3-CV-28B |