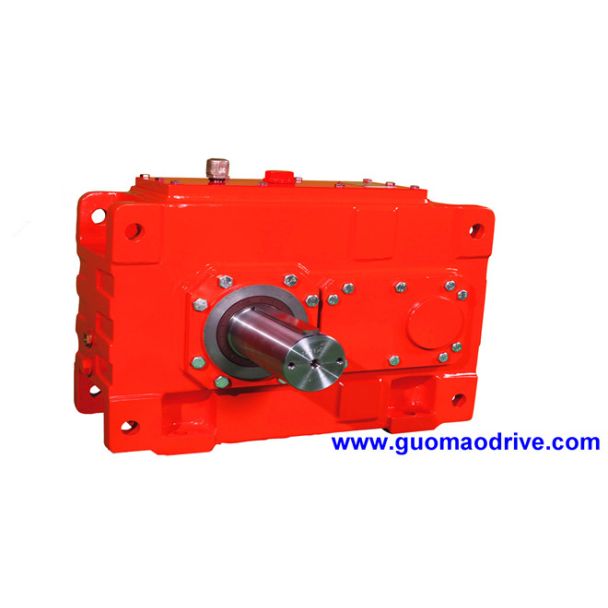

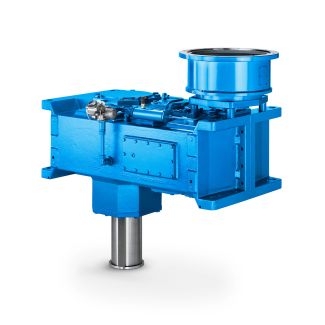

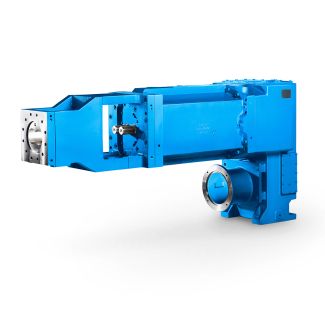

Helical gearbox H3 siemens flender gearbox catalogue H3-CV-28-D

In stock

SKU

H3-CV-28-D

$546,428.57

Flender/Flender Gear Units/Helical gearbox H3

direct processing, preferablyof sulphidic lead concentrates, into buion, settlableslag and S0-rich gas in single, closed reac- tor Moistconcentrates,fluxesand recycledfluedustaremoistenedandpelletised,andfed intothe reactor as green pellets The reactor is brick-lined, horizontal cylinder with bottom-blowing nozzles In case of malfunctions or scheduled shutdowns,

reactor as green pellets The reactor is brick-lined, horizontal cylinder with bottom-blowing nozzles In case of malfunctions or scheduled shutdowns,  the reactor can be tilted by 1" so that the nozzles can be removed from the bath In the oxidation

the reactor can be tilted by 1" so that the nozzles can be removed from the bath In the oxidation  zone, which is separated from the reduction zone by means of partition wall, oxygen is blown intooxidisethesulphur,andafraction ofthelead issimultaneouslyreducedto so-called

zone, which is separated from the reduction zone by means of partition wall, oxygen is blown intooxidisethesulphur,andafraction ofthelead issimultaneouslyreducedto so-called  primary lead While flowing to the slag tap, the PbO-containing slag passes through the reduction zone where the residual reduction is completed by blowing in pulverised coal - ~~~ __ ~ ~- ~ 9 The slag is continuously tapped from the reactor and granulated immediately, while all of the lead flows to the siphon-like aperture at the opposite end, where it is likewise tapped contin- uously. The exhaust gas, containing 1 to 2% SO2 by volume, is dedusted in hot-gas elec- trostatic precipitator and processed into sulphuric acid; the precipitated flue dust is recirculat- ed. In order to confirm the initial results obtained from the batchwise operation of 5,0 tpa pilot plant on the grounds of Berzelius Metallhutten GmbH, Duisburg, continuously operating, 3,0 tpa pilot plant for the environmentally clean and energysaving production of lead according to the QSL process was erected and operated. The objectives of this trial operation primarily included the following key areas: - Confirmation of the data obtained from batchwise operation of the pilot plant and elabora- - Confirmation of the technical functionality of the process, giving special consideration to - Compilation of the technical and metallurgical design data for up-scaling to the capacityof Proof of the metallurgical and technical feasibility of the rocess was

primary lead While flowing to the slag tap, the PbO-containing slag passes through the reduction zone where the residual reduction is completed by blowing in pulverised coal - ~~~ __ ~ ~- ~ 9 The slag is continuously tapped from the reactor and granulated immediately, while all of the lead flows to the siphon-like aperture at the opposite end, where it is likewise tapped contin- uously. The exhaust gas, containing 1 to 2% SO2 by volume, is dedusted in hot-gas elec- trostatic precipitator and processed into sulphuric acid; the precipitated flue dust is recirculat- ed. In order to confirm the initial results obtained from the batchwise operation of 5,0 tpa pilot plant on the grounds of Berzelius Metallhutten GmbH, Duisburg, continuously operating, 3,0 tpa pilot plant for the environmentally clean and energysaving production of lead according to the QSL process was erected and operated. The objectives of this trial operation primarily included the following key areas: - Confirmation of the data obtained from batchwise operation of the pilot plant and elabora- - Confirmation of the technical functionality of the process, giving special consideration to - Compilation of the technical and metallurgical design data for up-scaling to the capacityof Proof of the metallurgical and technical feasibility of the rocess was| Model Type | Helical gearbox H3 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 25500.000000 |

| Ratio Range | 1 : 25…100 |

| Low Speed Output | Solid shaft without parallel key |

| Nominal Torque | 1400000 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | Siemens AG |

| Country of Manufacture | Guatemala |

| Data Sheet & Drawings | Helical gearbox H3 siemens flender gearbox catalogue H3-CV-28-D |