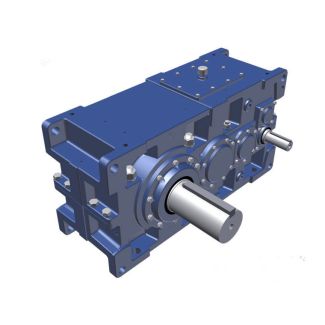

H2-FH26A flender mitarbeiter Helical gear reducers H2

In stock

SKU

H2-FH26A

$375,000.00

Flender/Flender Gear Units/Helical gear reducers H2

based upon common combinations of materials and various angles. TABLE 1. CONVEYOR APPLICATION FACTORS Material CombinationsAngle From The Horizontal 0 1 2 3 4 5 6 7 8 9 Pivoting bucket conveyor.0 .1 .3 .5 .6 .7 .8 .9 .9

1 2 3 4 5 6 7 8 9 Pivoting bucket conveyor.0 .1 .3 .5 .6 .7 .8 .9 .9  1.0 Belt on rollers .0 .1 .3 .5 .6 .7 .8 .9 .9 1.0 Metal on metal (finished) .2 .3

1.0 Belt on rollers .0 .1 .3 .5 .6 .7 .8 .9 .9 1.0 Metal on metal (finished) .2 .3  .5 .6 .8 .8 .9 1.0 1.0 1.0 Fabric on steel .2 .4 .6 .7 .8 .9 1.0 1.0 1.0

.5 .6 .8 .8 .9 1.0 1.0 1.0 Fabric on steel .2 .4 .6 .7 .8 .9 1.0 1.0 1.0  1.0 Fabric on wood .3 .4 .6 .7 .8 .9 1.0 1.0 1.0 1.0 Leather on wood .3 .5 .6 .8 .9 .9 1.0 1.0 1.0 1.0 Wood on wood .3 .5 .6 .8 .9 .9 1.0 1.0 1.0 1.0 Plastic on steel .3 .5 .6 .8 .9 .9 1.0 1.0 1.0 1.0 Metal on wood .4 .5 .7 .8 .9 1.0 1.0 1.0 1.0 1.0 Rubber on wood .4 .6 .7 .8 .9 1.0 1.0 1.0 1.0 1.0 Rubber on steel .5 .6 .8 .9 1.0 1.0 1.1 1.1 1.0 1.0 Leather on metal .5 .7 .8 .9 1.0 1.1 1.1 1.1 1.0 1.0 Interpolation in the table above is permissible . The procedure involves selection of the proper Applica tion Factor for the calculations: Belt Pull = (Total weight on conveyor) (Application Factor) Torque = (Belt Pull) (Radius of Head Pulley)For most applications, select for running torque rather than starting torque. The AC motor will normally pro duce 2 percent starting torque. The speed reducer is built to take at least 2% momentary overload to overcome normal starting inertia. The difference in the resulting cost can be startling. 2% safety factor in selection can double the life of the speed reducer for more economy in the long run. This rule of thumb will help compensate for unexpected shock and vibration, and add substantially to wear life. Consider auxiliary drives whenever possible for economy . properly selected gear or chain drive reduction from the reducer output to the driven shaft can produce substantial savings in space and drive cost. Avoid auxiliary drives to the input shaft unless absolutely necessary. Auxiliary reduction from the motor to the input shaft can increase the size and cost of the drive. Hoists Worm gear reducers are ideal for many hois

1.0 Fabric on wood .3 .4 .6 .7 .8 .9 1.0 1.0 1.0 1.0 Leather on wood .3 .5 .6 .8 .9 .9 1.0 1.0 1.0 1.0 Wood on wood .3 .5 .6 .8 .9 .9 1.0 1.0 1.0 1.0 Plastic on steel .3 .5 .6 .8 .9 .9 1.0 1.0 1.0 1.0 Metal on wood .4 .5 .7 .8 .9 1.0 1.0 1.0 1.0 1.0 Rubber on wood .4 .6 .7 .8 .9 1.0 1.0 1.0 1.0 1.0 Rubber on steel .5 .6 .8 .9 1.0 1.0 1.1 1.1 1.0 1.0 Leather on metal .5 .7 .8 .9 1.0 1.1 1.1 1.1 1.0 1.0 Interpolation in the table above is permissible . The procedure involves selection of the proper Applica tion Factor for the calculations: Belt Pull = (Total weight on conveyor) (Application Factor) Torque = (Belt Pull) (Radius of Head Pulley)For most applications, select for running torque rather than starting torque. The AC motor will normally pro duce 2 percent starting torque. The speed reducer is built to take at least 2% momentary overload to overcome normal starting inertia. The difference in the resulting cost can be startling. 2% safety factor in selection can double the life of the speed reducer for more economy in the long run. This rule of thumb will help compensate for unexpected shock and vibration, and add substantially to wear life. Consider auxiliary drives whenever possible for economy . properly selected gear or chain drive reduction from the reducer output to the driven shaft can produce substantial savings in space and drive cost. Avoid auxiliary drives to the input shaft unless absolutely necessary. Auxiliary reduction from the motor to the input shaft can increase the size and cost of the drive. Hoists Worm gear reducers are ideal for many hois| Model Type | Helical gear reducers H2 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 17500.000000 |

| Ratio Range | 1 : 7.1…22.4 |

| Low Speed Output | Flanged shaft |

| Nominal Torque | 1030000 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Flender Siemens |

| Country of Manufacture | China |

| Data Sheet & Drawings | H2-FH26A flender mitarbeiter Helical gear reducers H2 |