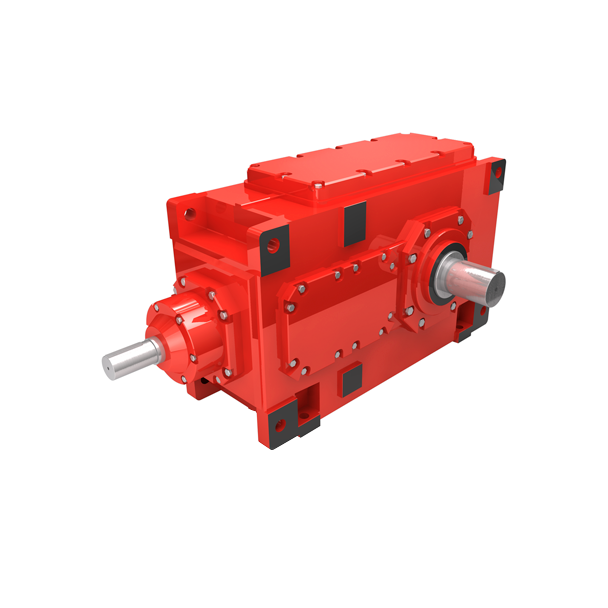

H2-FH-27-A flender power transmission Helical gear unit H2

In stock

SKU

H2-FH-27-A

$471,428.57

Flender/Flender Gear Units/Helical gear unit H2

bath, in order to attain longer bath service life and reduce the chemical input. total of eight new detergent types are introduced, four of which largely cover the current application ran of CHCsolvents and cold cleaners, while the remaining four

are introduced, four of which largely cover the current application ran of CHCsolvents and cold cleaners, while the remaining four  are intended for special cases.Tge detergent types were tested in industrial practice as alternatives to solvents and have been developed

are intended for special cases.Tge detergent types were tested in industrial practice as alternatives to solvents and have been developed  to such degree that they are ready for application. Thecomposition, mode of action and practical application of the new detergent

to such degree that they are ready for application. Thecomposition, mode of action and practical application of the new detergent  types are pre- sented and compared with solvent degreasing. Aspects of bath maintenance and control, and the treatment and disposal of spent baths are discussed. Possible solutions are proposed for the problems which still remained unsolved at the end of the project. 2 Duration: 0 1 8 - 3 0 9 0 ZH8A8 Subject: Reduction of halogenated hydrocarbon emissions - Sub-Project. Reduction of the environmental burden by reducing halogenated hydrocarbon emissions resulting from cleaning processes in the electrical industry . Research centre: Siemens AG Werner-von-Siemens-Strasse 5,9 Erlangen Government sponsorship: DM 1,8,6.0 Sponsorship ratio: 5% Duration: 0 1 8 - 3 0 9 0 ZH8B8 Subject: Reduction of halogenated hydrocarbon emissions - Sub-project: Reduction of the environmental burden by reducing halogenated hydrocarbon emissions resulting from cleaning processes in the electrical industry Research centre: Henkel KGaA Henkelstrasse 6,4 Dusseldorf Government sponsorship: DM 8,6 0 Sponsorship ratio: 4 / 1. Purpose of the project The goal of the project was considerably to reduce the consumption of halogenated hydrocar- bons by modifying production processesand designing environmentally friendly cleanin pro cesses The use of aqueous media is the rimary alternative cleaning process avalabli although this involves numerous roblems wfen, for example, different materials are cleaned simultaneously in the same instaration, the workpieces have

types are pre- sented and compared with solvent degreasing. Aspects of bath maintenance and control, and the treatment and disposal of spent baths are discussed. Possible solutions are proposed for the problems which still remained unsolved at the end of the project. 2 Duration: 0 1 8 - 3 0 9 0 ZH8A8 Subject: Reduction of halogenated hydrocarbon emissions - Sub-Project. Reduction of the environmental burden by reducing halogenated hydrocarbon emissions resulting from cleaning processes in the electrical industry . Research centre: Siemens AG Werner-von-Siemens-Strasse 5,9 Erlangen Government sponsorship: DM 1,8,6.0 Sponsorship ratio: 5% Duration: 0 1 8 - 3 0 9 0 ZH8B8 Subject: Reduction of halogenated hydrocarbon emissions - Sub-project: Reduction of the environmental burden by reducing halogenated hydrocarbon emissions resulting from cleaning processes in the electrical industry Research centre: Henkel KGaA Henkelstrasse 6,4 Dusseldorf Government sponsorship: DM 8,6 0 Sponsorship ratio: 4 / 1. Purpose of the project The goal of the project was considerably to reduce the consumption of halogenated hydrocar- bons by modifying production processesand designing environmentally friendly cleanin pro cesses The use of aqueous media is the rimary alternative cleaning process avalabli although this involves numerous roblems wfen, for example, different materials are cleaned simultaneously in the same instaration, the workpieces have| Model Type | Helical gear unit H2 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 22000.000000 |

| Ratio Range | 1 : 8…20 |

| Low Speed Output | Flanged shaft |

| Nominal Torque | 1230000 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | FLENDER GUSS GMBH |

| Country of Manufacture | Costa Rica |

| Data Sheet & Drawings | H2-FH-27-A flender power transmission Helical gear unit H2 |