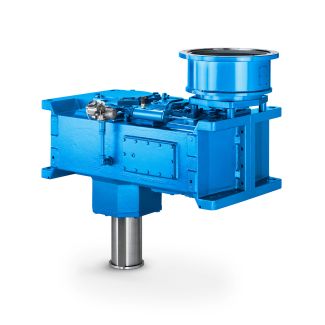

nal cooling options Overview Further cooling opti B4-KH17A Bevel-helical gear reducers B4

In stock

SKU

B4-KH17A

$100,607.14

Flender/Flender Gear Units/Bevel-helical gear reducers B4

use The gear unit has been manufactured in accordance with the state of the art and is delivered in condition for safe and reliable use. Any changes on the part of the user are not permitted. This applies equally to

for safe and reliable use. Any changes on the part of the user are not permitted. This applies equally to  safety features designed to prevent accidental contact. The gear unit must be used and operated strictly in accordance with the

safety features designed to prevent accidental contact. The gear unit must be used and operated strictly in accordance with the  conditions laid down in the contract governing performance and supply agreed by FLENDER and the customer. 3.2 Obligations of the

conditions laid down in the contract governing performance and supply agreed by FLENDER and the customer. 3.2 Obligations of the  user The operator must ensure that everyone carrying out work on the gear unit has read and understood the operating instructions and is adhering to them in every point: avoid injury or damage, ensure the safety and reliability of the unit, avoid disruptions and environmental damage through incorrect use. During tr ansport, assembly, installation, dismantling, operation and maintenance of the unit, the relevant safety and environmental regulations must be complied with at all times. The gear unit should be operated, maintained or repaired by authorised, trained and qualified personnel. The gear unit must not be cleaned using highpressure cleaning equipment. All work must be carried out with great care and with due regard to safety. All work on the gear unit must be carried out only when it is not in operation. The drive unit must be secured against being switched on accidentally (.. by locking the key switch or removing the fuses from the power supply). In addition the gear unit must be secured to the fan at the output side in such manner that the fan cannot drive the gear unit. notice should be attached to the start switch stating clearly that work is in progress. No welding work must be done on the gear unit. The gear unit must not be used as an earthing point for welding operations. Toothed parts and bearings may be irreparably damaged by welding. If any changes are noticed during operation (.. overheating or unusual noises), the drive assembly must be switched off immediately. Rota

user The operator must ensure that everyone carrying out work on the gear unit has read and understood the operating instructions and is adhering to them in every point: avoid injury or damage, ensure the safety and reliability of the unit, avoid disruptions and environmental damage through incorrect use. During tr ansport, assembly, installation, dismantling, operation and maintenance of the unit, the relevant safety and environmental regulations must be complied with at all times. The gear unit should be operated, maintained or repaired by authorised, trained and qualified personnel. The gear unit must not be cleaned using highpressure cleaning equipment. All work must be carried out with great care and with due regard to safety. All work on the gear unit must be carried out only when it is not in operation. The drive unit must be secured against being switched on accidentally (.. by locking the key switch or removing the fuses from the power supply). In addition the gear unit must be secured to the fan at the output side in such manner that the fan cannot drive the gear unit. notice should be attached to the start switch stating clearly that work is in progress. No welding work must be done on the gear unit. The gear unit must not be used as an earthing point for welding operations. Toothed parts and bearings may be irreparably damaged by welding. If any changes are noticed during operation (.. overheating or unusual noises), the drive assembly must be switched off immediately. Rota| Model Type | Bevel-helical gear reducers B4 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 4695.000000 |

| Ratio Range | 1 : 80…315 |

| Low Speed Output | Hollow shaft with spline acc. to DIN 5480 |

| Nominal Torque | 200000 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Flender Svenska AB |

| Country of Manufacture | Kyrgyzstan |

| Data Sheet & Drawings | nal cooling options Overview Further cooling opti B4-KH17A Bevel-helical gear reducers B4 |