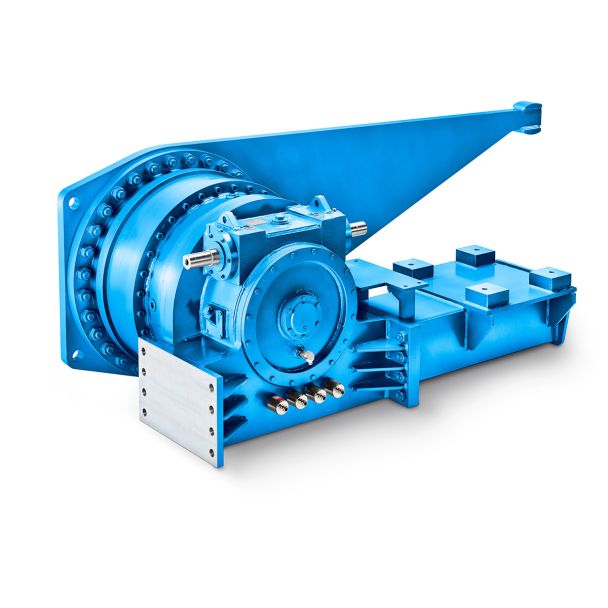

Bevel-helical gear box B4 als Overview Labyrinth seal Labyrinth seals are es B4-HV17A

In stock

SKU

B4-HV17A

$100,607.14

Flender/Flender Gear Units/Bevel-helical gear box B4

tracking to be more effective. In addition, we are pursuing multi - ronged strategy that is aimed at reducing the CO2 footprint in operations and in our supply chain. CO2-reduction measures for emissions from energy are coordinated globally and implemented

CO2 footprint in operations and in our supply chain. CO2-reduction measures for emissions from energy are coordinated globally and implemented  locally. All sites report ontheir progress regularly. We strengthened our ambitions in2by committing to set near andlong-term Company-wide emission reductions

locally. All sites report ontheir progress regularly. We strengthened our ambitions in2by committing to set near andlong-term Company-wide emission reductions  in line with the Science Based Targets initiative (SBTi) criteria. We have responded to the SBTis urgentcall for corporate climate

in line with the Science Based Targets initiative (SBTi) criteria. We have responded to the SBTis urgentcall for corporate climate  action through the Business Ambition for 1.5C campaign. Over the next months, we will develop targets to drive forward the goals of the Paris Agreement. Ourpositioned targets will be reviewed and validated by the SBTi. 4.4 ANAGING OUR CARBON EMISSIONS: OUR PATH TO NET-ZERO EMISSIONS CONTINUED ENVIRONMENTAL SUSTAINABILITY4 SUSTAINABILITY REPORT 2 4.4 ANAGING OUR CARBON EMISSIONS: OUR PATH TO NET-ZERO EMISSIONS CONTINUED REDUCING THE CARBON FOOTPRINT OFOUROPERATIONS GRI 3-1, 3-2, 3-3, 3-4, 3-5, 3-7 | SDG3.9, 1.4, 1.1 Between 2 and 2 we reduced CO 2 emissions inour own operations by 7.7%, mainly by switching to CO 2-neutral energy sources.1 An increase in our Scope 1 emissions can be observed in the 2 financial year following steady reduction over the last few years, dueto two factors: ur implementation of stricter requirements for balancing natural gas and including additional sites; and OVID-1 related increased ventilation requirements led to increased natural gasconsumption. Between 2 and 2, we were able to reduce ourScope 2 emissions by 9.6%. 1 he following gases were included in the calculation: carbon dioxide, methane, nitrous oxide and fluorinated gases (hydrofluorocarbons (HFCs), perfluorocarbons (PFCs), sulphur hexafluoride and nitrogen trifluoride (NF ). There were no biogenic CO2 emissions. he specified emission values do not include data on halogenated carbon from the si

action through the Business Ambition for 1.5C campaign. Over the next months, we will develop targets to drive forward the goals of the Paris Agreement. Ourpositioned targets will be reviewed and validated by the SBTi. 4.4 ANAGING OUR CARBON EMISSIONS: OUR PATH TO NET-ZERO EMISSIONS CONTINUED ENVIRONMENTAL SUSTAINABILITY4 SUSTAINABILITY REPORT 2 4.4 ANAGING OUR CARBON EMISSIONS: OUR PATH TO NET-ZERO EMISSIONS CONTINUED REDUCING THE CARBON FOOTPRINT OFOUROPERATIONS GRI 3-1, 3-2, 3-3, 3-4, 3-5, 3-7 | SDG3.9, 1.4, 1.1 Between 2 and 2 we reduced CO 2 emissions inour own operations by 7.7%, mainly by switching to CO 2-neutral energy sources.1 An increase in our Scope 1 emissions can be observed in the 2 financial year following steady reduction over the last few years, dueto two factors: ur implementation of stricter requirements for balancing natural gas and including additional sites; and OVID-1 related increased ventilation requirements led to increased natural gasconsumption. Between 2 and 2, we were able to reduce ourScope 2 emissions by 9.6%. 1 he following gases were included in the calculation: carbon dioxide, methane, nitrous oxide and fluorinated gases (hydrofluorocarbons (HFCs), perfluorocarbons (PFCs), sulphur hexafluoride and nitrogen trifluoride (NF ). There were no biogenic CO2 emissions. he specified emission values do not include data on halogenated carbon from the si| Model Type | Bevel-helical gear box B4 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 4695.000000 |

| Ratio Range | 1 : 80…315 |

| Low Speed Output | Hollow shaft with keyway acc. to DIN 6885/1 |

| Nominal Torque | 200000 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | Flender Siemens |

| Country of Manufacture | Russia |

| Data Sheet & Drawings | Bevel-helical gear box B4 als Overview Labyrinth seal Labyrinth seals are es B4-HV17A |