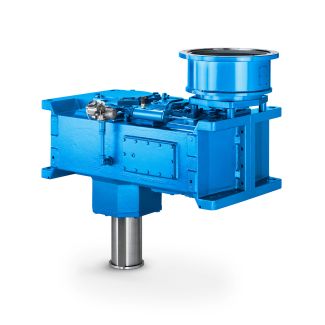

Bevel-helical gear boxes B4 y the view of the shaft face of the low speed shaf B4-FH-21B

In stock

SKU

B4-FH-21B

$197,142.86

Flender/Flender Gear Units/Bevel-helical gear boxes B4

with torque limiting L1 Design with torque limiting, attachment prepared L1 Design with torque limiting for ATEX L1 Design with torque limiting for ATEX, attachment prepared L1 Direction of rotation, looking at low speed shaft extension (LSS): Clockwise L9 Direction

torque limiting for ATEX, attachment prepared L1 Direction of rotation, looking at low speed shaft extension (LSS): Clockwise L9 Direction  of rotation, looking at low spee shaft extension (LSS): Counter-clockwise L9 Direction of rotation, looking at low speed shaft extension

of rotation, looking at low spee shaft extension (LSS): Counter-clockwise L9 Direction of rotation, looking at low speed shaft extension  (LSS), shaft journals on side 3 L9 Direction of rotation, looking at low speed shaft extension (LSS), shaft journals on

(LSS), shaft journals on side 3 L9 Direction of rotation, looking at low speed shaft extension (LSS), shaft journals on  side 6 L9G_MD2_XX_0 3Irrespective of the mounting position of the gear unit, the face desig- nations "right" and "left" always refer to the horizontal mounting posi- tion with the view on side 1. Side 2 is on top. Mounting cover on top (, looking at drive front face (: Side 3 = right Side 6 = left Flender GmbH 2NER GROUP CO.,LIMITED Germany sogears HB series gearbox 1/2 Flender MD 2.1 2Options for operation Information about oil, information about installation Overview Information about oil Flender FZG gear units are supplied without oil filling as standard. Ordering information: The following options can be selected by ordering the gear units with the order code -: Permissible type of oil Different types of oils can be selected in the selection tool. Permitted oil viscosities (for recommendations, see page 1/1 ) Information about installation Ordering information: The following options regarding altitude and installation location are selected using the order code -: Altitude Installation locationData position of the Article No. 1 to 6 7 8 1Order code Article No.: 2LP3 .-.....-....- Permissible type of oil Provided for mineral oil H0 Provided for synthetic oil on polyalphaolefin basis (PAO oil) H0 Provided for synthetic low temperature oil on polyalphaolefin basis (PAO- oil) Suitable for ambient temperatures colder than -3 . H0 Data position of the Article No. 1 to 6 7 8 1Order code Article No.: 2LP3 .-.....-....- Oil viscosity ISO VG H1 ISO

side 6 L9G_MD2_XX_0 3Irrespective of the mounting position of the gear unit, the face desig- nations "right" and "left" always refer to the horizontal mounting posi- tion with the view on side 1. Side 2 is on top. Mounting cover on top (, looking at drive front face (: Side 3 = right Side 6 = left Flender GmbH 2NER GROUP CO.,LIMITED Germany sogears HB series gearbox 1/2 Flender MD 2.1 2Options for operation Information about oil, information about installation Overview Information about oil Flender FZG gear units are supplied without oil filling as standard. Ordering information: The following options can be selected by ordering the gear units with the order code -: Permissible type of oil Different types of oils can be selected in the selection tool. Permitted oil viscosities (for recommendations, see page 1/1 ) Information about installation Ordering information: The following options regarding altitude and installation location are selected using the order code -: Altitude Installation locationData position of the Article No. 1 to 6 7 8 1Order code Article No.: 2LP3 .-.....-....- Permissible type of oil Provided for mineral oil H0 Provided for synthetic oil on polyalphaolefin basis (PAO oil) H0 Provided for synthetic low temperature oil on polyalphaolefin basis (PAO- oil) Suitable for ambient temperatures colder than -3 . H0 Data position of the Article No. 1 to 6 7 8 1Order code Article No.: 2LP3 .-.....-....- Oil viscosity ISO VG H1 ISO| Model Type | Bevel-helical gear boxes B4 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 9200.000000 |

| Ratio Range | 1 : 80…315 |

| Low Speed Output | Flanged shaft |

| Nominal Torque | 420000 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | FLENOER-GRAFFENSTA |

| Country of Manufacture | Germany |

| Data Sheet & Drawings | Bevel-helical gear boxes B4 y the view of the shaft face of the low speed shaf B4-FH-21B |