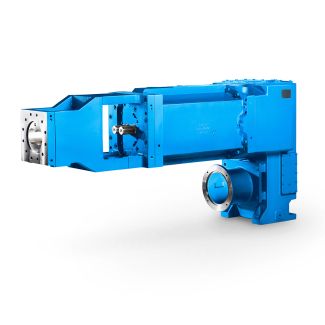

Bevel-helical gear unit B4 ackstop Sz Backstop Sz Design Helical gea B4FH-22-C

In stock

SKU

B4FH-22-C

$212,142.86

Flender/Flender Gear Units/Bevel-helical gear unit B4

without hot gas generator and consequently water injection for the purpose of grinding bed stabilisation was not permitted. Loesche looked at the customers requirements before deciding on the best solution. The main constituents to be ground were clinker, fly OPTIMISED

at the customers requirements before deciding on the best solution. The main constituents to be ground were clinker, fly OPTIMISED  GRINDING Figure 3: assumed grindability for Ambuja Cements Dadri and Nalagarh projects JUNE 2 INTERNATIONAL CEMENT REVIEWash and gypsum (up

GRINDING Figure 3: assumed grindability for Ambuja Cements Dadri and Nalagarh projects JUNE 2 INTERNATIONAL CEMENT REVIEWash and gypsum (up  to five per cent) all of which have different physical properties basically leading to different grindabilities and particular individual behaviour

to five per cent) all of which have different physical properties basically leading to different grindabilities and particular individual behaviour  inside the mill.Standard procedure is to carry out grinding test to establish proper sizing for the mill and the gear box. However, at the start of both of the projects it was not known where the different fly ash or clinker sources would be sourced. Therefore, Loesche had to assume certain grindability factor and specific power consumption for the feed mix (see Figure . The assumptions were based on Loesches experience and knowledge of other fly ash cement grinding plants operating in India. Loesche concluded that it would need 5.3+3 mill with table diameter of 5.6m. The selected Flender gear box would have power consumption of 5kW, Loesche dynamic classifier LSKS 1CS and fan motor of 3kW would form the other main parts of the system (see Table . Loesches scope of supply for the two Indian projects was not for the whole grinding plants, but for the mills, classifiers, sampling stations and the air slides for the product transport. Loesches product targets were PPC of 4Blaine at 2tph using specific power consumption of 3.7kWh/ for all the Loesche equipment and the fan supply (see Table . The PPC product would consist of 6 per cent clinker, five per cent gypsum and 3 per cent fly ash (2 Blaine). If the plant receives clinker that is high in 3S then the fly ash content can be increased to the maximum permissible according to Indian standards. If the clinker exhibits low 3S value, the plant can

inside the mill.Standard procedure is to carry out grinding test to establish proper sizing for the mill and the gear box. However, at the start of both of the projects it was not known where the different fly ash or clinker sources would be sourced. Therefore, Loesche had to assume certain grindability factor and specific power consumption for the feed mix (see Figure . The assumptions were based on Loesches experience and knowledge of other fly ash cement grinding plants operating in India. Loesche concluded that it would need 5.3+3 mill with table diameter of 5.6m. The selected Flender gear box would have power consumption of 5kW, Loesche dynamic classifier LSKS 1CS and fan motor of 3kW would form the other main parts of the system (see Table . Loesches scope of supply for the two Indian projects was not for the whole grinding plants, but for the mills, classifiers, sampling stations and the air slides for the product transport. Loesches product targets were PPC of 4Blaine at 2tph using specific power consumption of 3.7kWh/ for all the Loesche equipment and the fan supply (see Table . The PPC product would consist of 6 per cent clinker, five per cent gypsum and 3 per cent fly ash (2 Blaine). If the plant receives clinker that is high in 3S then the fly ash content can be increased to the maximum permissible according to Indian standards. If the clinker exhibits low 3S value, the plant can| Model Type | Bevel-helical gear unit B4 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 9900.000000 |

| Ratio Range | 1 : 90…355 |

| Low Speed Output | Flanged shaft |

| Nominal Torque | 470000 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Flender GmbH |

| Country of Manufacture | Saudi Arabia |

| Data Sheet & Drawings | Bevel-helical gear unit B4 ackstop Sz Backstop Sz Design Helical gea B4FH-22-C |