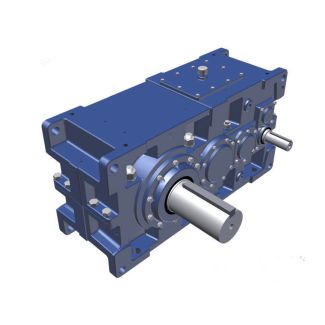

B4-CV17A tering DS form with thread according to DIN Ra L Bevel-helical gear Reduction Box B4

In stock

SKU

B4-CV17A

$100,607.14

Flender/Flender Gear Units/Bevel-helical gear Reduction Box B4

the way bevel gears mesh under load.This may in turn produce signicant effects on the dynamics of the transmissionchain (see Sect. 5.. Since tooth segments of varying stiffnesses are engaged in each meshing position, the transmission error, specied as an

Sect. 5.. Since tooth segments of varying stiffnesses are engaged in each meshing position, the transmission error, specied as an  arc/distance (at radius wm) or as an angle, uctuates as function of the rotation position. The transmission error in the

arc/distance (at radius wm) or as an angle, uctuates as function of the rotation position. The transmission error in the  normal tooth section represents angle zdescribed in Sect. 4.4.3.2 and related to the pinion, and may be taken directly from

normal tooth section represents angle zdescribed in Sect. 4.4.3.2 and related to the pinion, and may be taken directly from  the solution vector of the system of equations used to calculate load distribution (Formula(4.). The calculation is performed for each mesh position iand is projected in the transverse section such that the transmission error for the entire tooth engagementis known. The total transmission error gesis formed from the sum of the load-free transmission error korrand the rotation angle error under load /C1cosm. Total transmission error geskorrz/C1cosm 4:3 Tooth stiffness governs the excitation of additional internal dynamic forces and gear noise as well as the resonance frequency of the gear pair. Tooth stiffnessrepresents the ratio between an applied force and the resulting deection. Theoret- ically, under load, all points on the contact lines are in contact; this state is1 4 Load Capacity and Efciency approximately reached at the rated load of the gear. The tooth stiffness ctheo( acting in the transverse section at meshing position 1is the sum of all tooth section stiffnesses ciin the normal section. Tooth stiffness ctheo1 cosm/C1Xn i1ci1 4:3 with: Fnitooth force acting at segment fki distance from ank contact at segment ci1 Fni z1 /C1 rwmfki4:3 By calculating the above tooth stiffness for each segment along the face width and introducing corrective factor CM(by analogy with DIN for contact elasticity components not covered in the calculation, such as surface roughness and lubricant, it is possible to obtain the specic contact stiffness cat meshing position

the solution vector of the system of equations used to calculate load distribution (Formula(4.). The calculation is performed for each mesh position iand is projected in the transverse section such that the transmission error for the entire tooth engagementis known. The total transmission error gesis formed from the sum of the load-free transmission error korrand the rotation angle error under load /C1cosm. Total transmission error geskorrz/C1cosm 4:3 Tooth stiffness governs the excitation of additional internal dynamic forces and gear noise as well as the resonance frequency of the gear pair. Tooth stiffnessrepresents the ratio between an applied force and the resulting deection. Theoret- ically, under load, all points on the contact lines are in contact; this state is1 4 Load Capacity and Efciency approximately reached at the rated load of the gear. The tooth stiffness ctheo( acting in the transverse section at meshing position 1is the sum of all tooth section stiffnesses ciin the normal section. Tooth stiffness ctheo1 cosm/C1Xn i1ci1 4:3 with: Fnitooth force acting at segment fki distance from ank contact at segment ci1 Fni z1 /C1 rwmfki4:3 By calculating the above tooth stiffness for each segment along the face width and introducing corrective factor CM(by analogy with DIN for contact elasticity components not covered in the calculation, such as surface roughness and lubricant, it is possible to obtain the specic contact stiffness cat meshing position| Model Type | Bevel-helical gear Reduction Box B4 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 4695.000000 |

| Ratio Range | 1 : 80…315 |

| Low Speed Output | Solid shaft without parallel key |

| Nominal Torque | 200000 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | A. Friedr. Flender GmbH |

| Country of Manufacture | Monaco |

| Data Sheet & Drawings | B4-CV17A tering DS form with thread according to DIN Ra L Bevel-helical gear Reduction Box B4 |