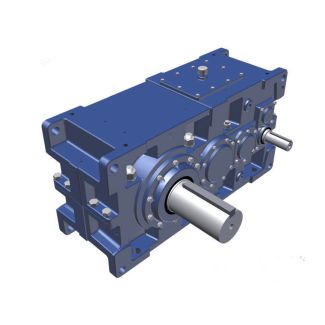

B4-CV-17B SSD H dhfgG G d I l l dminsrmax Ra m t DDm d c M Bevel-helical gear units B4

In stock

SKU

B4-CV-17B

$100,607.14

Flender/Flender Gear Units/Bevel-helical gear units B4

the West German DIN standards. ISO standards, which are still developing, are also followed. JIS and JGMA standards are similar to AGMA standards, and licensed products are generally made to either the AGMA or DIN standards, or some proprietary rating

to AGMA standards, and licensed products are generally made to either the AGMA or DIN standards, or some proprietary rating  system based on published standards and company experience. One Japanese manufacturer noted that in Japan, AGMA standards cannot be followed

system based on published standards and company experience. One Japanese manufacturer noted that in Japan, AGMA standards cannot be followed  exactly, because Japanese steel 1 The JGMA represents total of 1 members: 1 gear producing establishments and 1 suppliers to

exactly, because Japanese steel 1 The JGMA represents total of 1 members: 1 gear producing establishments and 1 suppliers to  the gear industry. the 1 members account for approximately 7 to 8 percent of industrial gearing production, excluding most captive production for automotive, marine, and aerospace industries. differs from .. stee1. 1 Also, the production of gear boxes with nonmetric shafts and bearings marginally raises production cost and requires additional quality control efforts. In developing standards, the JGMA membership fees and company donations of personnel and other resources cover most of the standards development expenditures. small amount is funded by the Japan Standards Association. 1 Annual direct expenditures by the JGMA on standards development are estimated at $2,0, excluding company expenses or transportation costs. Korea Industry and trade profile The Korean gear industry developed in the late 1s and has grown rapidly. The development of the industry was heavily influenced by the influx of Japanese and European 'manufacturers of vehicle and industrial gearing. There are an estimated 5 mostly small- to medium-sized gearing producers in Korea today, with few large producers as well, mostly in the vehicle and industrial gearing sectors (table 5-. Imports still account for roughly one-half of domestic demand and exports are low. The unusually low amount of exports is in large part due to the use of Korean production as parts of finished products, such as automobiles. Motor vehicle gears and gearing are an

the gear industry. the 1 members account for approximately 7 to 8 percent of industrial gearing production, excluding most captive production for automotive, marine, and aerospace industries. differs from .. stee1. 1 Also, the production of gear boxes with nonmetric shafts and bearings marginally raises production cost and requires additional quality control efforts. In developing standards, the JGMA membership fees and company donations of personnel and other resources cover most of the standards development expenditures. small amount is funded by the Japan Standards Association. 1 Annual direct expenditures by the JGMA on standards development are estimated at $2,0, excluding company expenses or transportation costs. Korea Industry and trade profile The Korean gear industry developed in the late 1s and has grown rapidly. The development of the industry was heavily influenced by the influx of Japanese and European 'manufacturers of vehicle and industrial gearing. There are an estimated 5 mostly small- to medium-sized gearing producers in Korea today, with few large producers as well, mostly in the vehicle and industrial gearing sectors (table 5-. Imports still account for roughly one-half of domestic demand and exports are low. The unusually low amount of exports is in large part due to the use of Korean production as parts of finished products, such as automobiles. Motor vehicle gears and gearing are an| Model Type | Bevel-helical gear units B4 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 4695.000000 |

| Ratio Range | 1 : 80…315 |

| Low Speed Output | Solid shaft without parallel key |

| Nominal Torque | 200000 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | flanders electric peru s a c |

| Country of Manufacture | Mongolia |

| Data Sheet & Drawings | B4-CV-17B SSD H dhfgG G d I l l dminsrmax Ra m t DDm d c M Bevel-helical gear units B4 |