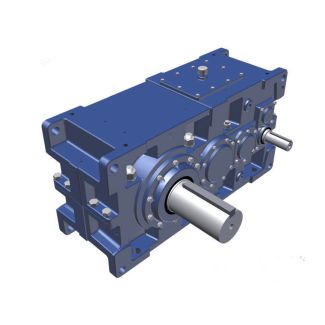

B4CV-17-C aterial of driven machine shaft CN or higher stren Bevel-helical gearboxes B4

In stock

SKU

B4CV-17-C

$100,607.14

Flender/Flender Gear Units/Bevel-helical gearboxes B4

thed. Vol. 2. Winnipeg, MB: Canadian International Grain Institute, pp. 5. Harvesting and Threshing ADHIR . DATTA Indian Institute of Technology, Kharagpur, India 1 INTRODUCTION In preparing quality grains and seeds from cereal and pulse crops for consumers, it is

Technology, Kharagpur, India 1 INTRODUCTION In preparing quality grains and seeds from cereal and pulse crops for consumers, it is  desirable that these be separated from the matured crop plants. All grains from paddy and wheat must be effectively stripped

desirable that these be separated from the matured crop plants. All grains from paddy and wheat must be effectively stripped  from the whole plant stem; gram, mustard, pigeon pea, lentil, and soybean must be threshed for seed from the plants,

from the whole plant stem; gram, mustard, pigeon pea, lentil, and soybean must be threshed for seed from the plants,  peanuts must be threshedor picked from the vines; and corn must be shelled from the cob. It will not be possibleto separate the seeds and grains from different crops with single machine. In removingseeds or grains from the plant stem effectively, series of operations are performed bythe individual process elements as the material passes through it. These functional ele- ments are put together to form successful machine called combine harvester .Acombine is, therefore, combined harvesterthresher put together to harvest all the small grains(such as cereals, pulses, oilseeds, and millets), sorghums, soybeans, and many other crops.Such machines are quite large, requiring high-capacity power source (3 kW) be-sides requiring large elds, highly skilled operators, and technicians to use and maintainthem. On the other hand, large-category farmer, growing more than one crop cannot afford separate combine for each crop and, also, maintain it over the year for next season. High-overhead cost, lack of technical know-how of functional elements, availability ofgenuine spares, periodic maintenance, loss of grain, and adaptability of combine as amultiharvest machine are the prime hurdles in making the decision to purchase combine.In spite of these difculties, cereals and pulse crop combines as harvester and thresherare becoming popular in all the countries where labor is scarce at the peak period ofharvest, and where manual harvesting and threshing operations are costly. Pr

peanuts must be threshedor picked from the vines; and corn must be shelled from the cob. It will not be possibleto separate the seeds and grains from different crops with single machine. In removingseeds or grains from the plant stem effectively, series of operations are performed bythe individual process elements as the material passes through it. These functional ele- ments are put together to form successful machine called combine harvester .Acombine is, therefore, combined harvesterthresher put together to harvest all the small grains(such as cereals, pulses, oilseeds, and millets), sorghums, soybeans, and many other crops.Such machines are quite large, requiring high-capacity power source (3 kW) be-sides requiring large elds, highly skilled operators, and technicians to use and maintainthem. On the other hand, large-category farmer, growing more than one crop cannot afford separate combine for each crop and, also, maintain it over the year for next season. High-overhead cost, lack of technical know-how of functional elements, availability ofgenuine spares, periodic maintenance, loss of grain, and adaptability of combine as amultiharvest machine are the prime hurdles in making the decision to purchase combine.In spite of these difculties, cereals and pulse crop combines as harvester and thresherare becoming popular in all the countries where labor is scarce at the peak period ofharvest, and where manual harvesting and threshing operations are costly. Pr| Model Type | Bevel-helical gearboxes B4 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 4695.000000 |

| Ratio Range | 1 : 80…315 |

| Low Speed Output | Solid shaft without parallel key |

| Nominal Torque | 200000 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | Flender Guss Gmbh & Co. Kg |

| Country of Manufacture | Montenegro |

| Data Sheet & Drawings | B4CV-17-C aterial of driven machine shaft CN or higher stren Bevel-helical gearboxes B4 |