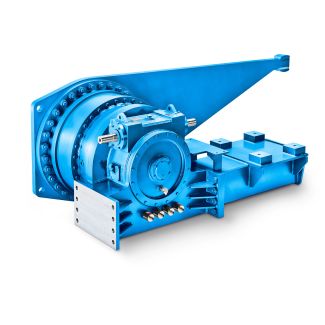

Gear unit sizeHigh speed shaft HSS Fan Reinforced B3DH-7-C Bevel-helical gear reducers B3

In stock

SKU

B3DH-7-C

$15,000.00

Flender/Flender Gear Units/Bevel-helical gear reducers B3

ransfer behaviourof the future refrigerant R1a under practical conditions. - Clarification of the question whether the conversion costs for substitution of the previously used refri erants can be at least partially amortised through the reduced operating costs resulting $om more

of the previously used refri erants can be at least partially amortised through the reduced operating costs resulting $om more  efficient heat exchangers if the standard tubing in existing systems is replaced by enhanced tubing. - Reduction of the environmental

efficient heat exchangers if the standard tubing in existing systems is replaced by enhanced tubing. - Reduction of the environmental  risk (ozone depletion and global warming) by creating reliable design principlesfor shell-and-tube evaporators and condensers optimised in terms of minimising

risk (ozone depletion and global warming) by creating reliable design principlesfor shell-and-tube evaporators and condensers optimised in terms of minimising  their refrigerant charge. Practice-oriented experimental comparisons are to be performed in order to demonstrate to the manufacturers of refrigerating and air-conditioning systems - how evaporators and condensers work with the hitherto unfamiliar, new refri erant with standard and enhanced tubes; the data obtained are to form the basis for tte low-risk design of evaporators and condensers; - how refrigerant quantities can be minimised (exact design of the heat exchangers on the basis of recise knowledge of the thermal conditions in large tube banks and use of enhanced hned tubes). 2 2. Working steps - Running-in of the experimental installation - Measurements with oil-free R1a and standard finned tubes - Measurements with oil-free R1a and enhanced finned tubes - Measurements with different oil concentrations and both standard and enhanced finned tubes 3. Results The main objective of the investigations was to establish the extent to which enhanced finned tubes -as osed to standard finned tubes - permit more compact system components to be designel& refrigerating machines and heat pumps The shell-and-tube equipment tested revealed considerable performance advantages for enhanced finned tubes in the evaporation and condensation of R1a As compared to standard finned tubes, the improvement was in the region of 4 to 5% for evaporation and between 3 and 4% for condensation In

their refrigerant charge. Practice-oriented experimental comparisons are to be performed in order to demonstrate to the manufacturers of refrigerating and air-conditioning systems - how evaporators and condensers work with the hitherto unfamiliar, new refri erant with standard and enhanced tubes; the data obtained are to form the basis for tte low-risk design of evaporators and condensers; - how refrigerant quantities can be minimised (exact design of the heat exchangers on the basis of recise knowledge of the thermal conditions in large tube banks and use of enhanced hned tubes). 2 2. Working steps - Running-in of the experimental installation - Measurements with oil-free R1a and standard finned tubes - Measurements with oil-free R1a and enhanced finned tubes - Measurements with different oil concentrations and both standard and enhanced finned tubes 3. Results The main objective of the investigations was to establish the extent to which enhanced finned tubes -as osed to standard finned tubes - permit more compact system components to be designel& refrigerating machines and heat pumps The shell-and-tube equipment tested revealed considerable performance advantages for enhanced finned tubes in the evaporation and condensation of R1a As compared to standard finned tubes, the improvement was in the region of 4 to 5% for evaporation and between 3 and 4% for condensation In| Model Type | Bevel-helical gear reducers B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 700.000000 |

| Ratio Range | 1 : 12.5…71 |

| Low Speed Output | Hollow shaft with shrink disk |

| Nominal Torque | 21700 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Flender Svenska AB |

| Country of Manufacture | Qatar |

| Data Sheet & Drawings | Gear unit sizeHigh speed shaft HSS Fan Reinforced B3DH-7-C Bevel-helical gear reducers B3 |