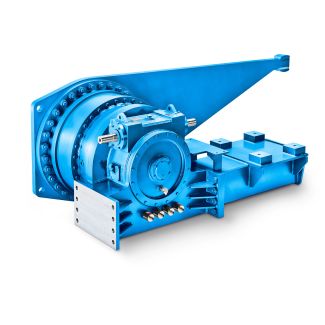

Air intake Fan GMDENLSS approx D sddn nm B3-DH-7-D Bevel-helical speed reducers B3

In stock

SKU

B3-DH-7-D

$15,000.00

Flender/Flender Gear Units/Bevel-helical speed reducers B3

ranted by the COMPANY shall not relieve the CONTRACTOR of his responsibilities and guarantees. 4.0 RADIATION SOURCE 4.1 Radiographic examination shall be carried out using -radi ations. Radiographic examination by Gamma rays may be allowed, at the discretion of the

shall be carried out using -radi ations. Radiographic examination by Gamma rays may be allowed, at the discretion of the  COMPANY, in case of inaccessible joints. 4.2 Whenever possible, pipeline welds will be inspected by placing the radiation source inside

COMPANY, in case of inaccessible joints. 4.2 Whenever possible, pipeline welds will be inspected by placing the radiation source inside  the pipe, on the pipeline axis, with radiation of 6.2 rad. (3 ). If it is impossible to place the

the pipe, on the pipeline axis, with radiation of 6.2 rad. (3 ). If it is impossible to place the  radiation source inside the pipe, the weld will be inspected with the source on the outside. An overlap of at leas 4mm at the ends of each film shall be required to ensure that the first and last ocation increment numbers are common to successive films and to establish that no part of weld has been omitted. 5.0 LEVEL OF QUALITY The quality level of radiographic sensitivity required for ra diographic inspection shall be at least equivalent to the values in Figure-6. 6.0 PENETRAMETERS 6.1 The image quality indicator (abbreviation : IQI) shall be used for the qualification of the welding procedure and during normal line production. Radiog raphic sensitivity shall be measured with the wire image quality indicator (Penetrameter ). The penetrameter shall be selected according to DIN 5 or ISO 1. For radiographs made with the source on the outside, penetrameter shall be placed on each side of the film with the smaller wire of the penetrameter turned towards the end of the film itself. When complete weld is radiographed in single exposure using source inside the piping, 1 of 1 STANDARD TECHNICAL SPECIFICATION MECON LIMITED REGD. OFF: RANCHI 8 OIL & GAS SBU, DELHI DOCUMENT NO. Page 5 of 6 TITLE MEC//0/2/0 REVISION : 0 PIPING FABRICATION AND ERECTION EDITION : 1 four penetrameters approximately equally spaced around the circ umference shall be used. During the procedure qualification, IQI shall be placed oth on the source side and on the fil

radiation source inside the pipe, the weld will be inspected with the source on the outside. An overlap of at leas 4mm at the ends of each film shall be required to ensure that the first and last ocation increment numbers are common to successive films and to establish that no part of weld has been omitted. 5.0 LEVEL OF QUALITY The quality level of radiographic sensitivity required for ra diographic inspection shall be at least equivalent to the values in Figure-6. 6.0 PENETRAMETERS 6.1 The image quality indicator (abbreviation : IQI) shall be used for the qualification of the welding procedure and during normal line production. Radiog raphic sensitivity shall be measured with the wire image quality indicator (Penetrameter ). The penetrameter shall be selected according to DIN 5 or ISO 1. For radiographs made with the source on the outside, penetrameter shall be placed on each side of the film with the smaller wire of the penetrameter turned towards the end of the film itself. When complete weld is radiographed in single exposure using source inside the piping, 1 of 1 STANDARD TECHNICAL SPECIFICATION MECON LIMITED REGD. OFF: RANCHI 8 OIL & GAS SBU, DELHI DOCUMENT NO. Page 5 of 6 TITLE MEC//0/2/0 REVISION : 0 PIPING FABRICATION AND ERECTION EDITION : 1 four penetrameters approximately equally spaced around the circ umference shall be used. During the procedure qualification, IQI shall be placed oth on the source side and on the fil| Model Type | Bevel-helical speed reducers B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 700.000000 |

| Ratio Range | 1 : 12.5…71 |

| Low Speed Output | Hollow shaft with shrink disk |

| Nominal Torque | 21700 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Flender ATB-Loher |

| Country of Manufacture | Romania |

| Data Sheet & Drawings | Air intake Fan GMDENLSS approx D sddn nm B3-DH-7-D Bevel-helical speed reducers B3 |