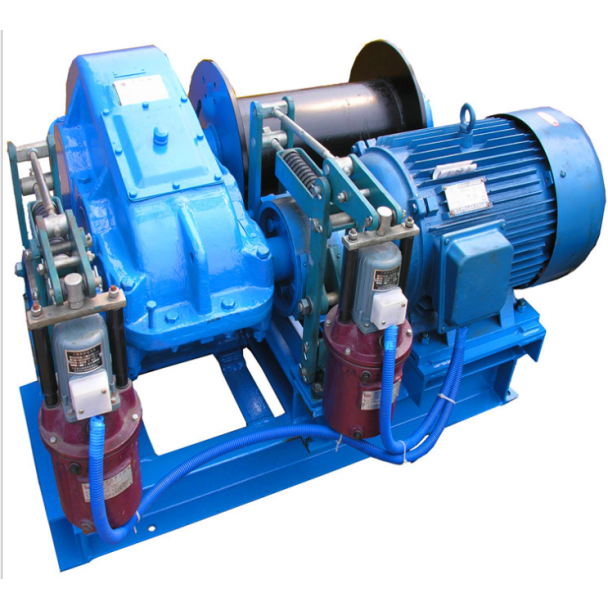

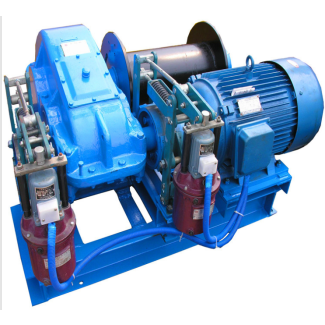

B3CV-12-C kg Hollow shaft for shrink disk HDV H C Bevel-helical speed reduction gearboxes B3

In stock

SKU

B3CV-12-C

$40,714.29

Flender/Flender Gear Units/Bevel-helical speed reduction gearboxes B3

per, levelling of build-ups with heated flat stamp, removal of the workpiece. The relationship between the parameters (temperature, stamping pressure and stamping time) is decisive for the quality of hotstamping. (primarily cylindrical surfaces) 7 3.3 Development of an inexpensive manufacturing

and stamping time) is decisive for the quality of hotstamping. (primarily cylindrical surfaces) 7 3.3 Development of an inexpensive manufacturing  process for stamping blocks In the course of development work, it became evident that the manufacture of the stamping block

process for stamping blocks In the course of development work, it became evident that the manufacture of the stamping block  has considerable influence on the quality of stamping as regards contour accuracy, material structure and heat transfer Master patterns or

has considerable influence on the quality of stamping as regards contour accuracy, material structure and heat transfer Master patterns or  films are usually the basis for the profile of the stamp geometry With the help of newly developed manufacturing process, the blocks are either assembled from modules, or cut from sheet steel using laser technology These individual arts are ass- embled on steel plate and filled with high temperatureresistant (over 3 "Cyepoxy resin This manufacturing process was patented during the course of the project Demands on the substrates Printed conductor substrates In principle,all thermoplasticsand cardboards which tolerateat least brief heating upto thesol- dering temperature and can be produced with adequate dimensional accuracy, such as PC, PA, PAR, PBT, PET, can be used as substrates forthe printed conductors The materials can be rein- forced with glass fibres Printed conductor substrates - Further processing Further processing techniques for PCBs with hot-stamped integrated printed conductors are soldering, drilling and preservation of the printed conductors During the course of this research project, pilot installation for continuous production of the hot-stamping foil (Cu backin sheet) and laminating machine for application of the various layers (parting and adhesiveyayers) were developed. This pilot installation was the basis for the design of the mass-production installation pilot installation was also built for the semi-automatic hotstamping method 3.4 Prospects for product design

films are usually the basis for the profile of the stamp geometry With the help of newly developed manufacturing process, the blocks are either assembled from modules, or cut from sheet steel using laser technology These individual arts are ass- embled on steel plate and filled with high temperatureresistant (over 3 "Cyepoxy resin This manufacturing process was patented during the course of the project Demands on the substrates Printed conductor substrates In principle,all thermoplasticsand cardboards which tolerateat least brief heating upto thesol- dering temperature and can be produced with adequate dimensional accuracy, such as PC, PA, PAR, PBT, PET, can be used as substrates forthe printed conductors The materials can be rein- forced with glass fibres Printed conductor substrates - Further processing Further processing techniques for PCBs with hot-stamped integrated printed conductors are soldering, drilling and preservation of the printed conductors During the course of this research project, pilot installation for continuous production of the hot-stamping foil (Cu backin sheet) and laminating machine for application of the various layers (parting and adhesiveyayers) were developed. This pilot installation was the basis for the design of the mass-production installation pilot installation was also built for the semi-automatic hotstamping method 3.4 Prospects for product design| Model Type | Bevel-helical speed reduction gearboxes B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 1900.000000 |

| Ratio Range | 1 : 16…90 |

| Low Speed Output | Solid shaft without parallel key |

| Nominal Torque | 77200 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | Flender GmbH |

| Country of Manufacture | Vanuatu |

| Data Sheet & Drawings | B3CV-12-C kg Hollow shaft for shrink disk HDV H C Bevel-helical speed reduction gearboxes B3 |