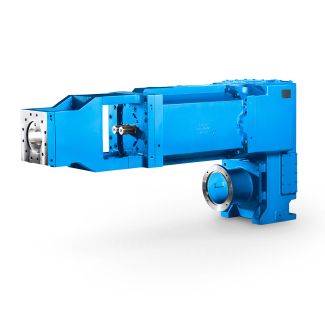

B3CV-11-C th to th position see pages to Article No L Bevel-helical gearboxes B3

In stock

SKU

B3CV-11-C

$40,285.71

Flender/Flender Gear Units/Bevel-helical gearboxes B3

pendicularly or at least at constantangle. When compared to laser hardening, electron beam hardening has higherenergy density, but vacuum is required. Due to these restrictions, laser or electron beam hardening can be used only to very limited extent for gear

required. Due to these restrictions, laser or electron beam hardening can be used only to very limited extent for gear  hardening. 6.3.4 Thermo-chemical Processes 6.3.4.1 Advantages of the Processes Gear-typical stresses on the material are essentially the contact stress on

hardening. 6.3.4 Thermo-chemical Processes 6.3.4.1 Advantages of the Processes Gear-typical stresses on the material are essentially the contact stress on  the tooth ank and the bending stress in the root. Their inuence on material choice wasdiscussed in Sect. 3.5.3 ,

the tooth ank and the bending stress in the root. Their inuence on material choice wasdiscussed in Sect. 3.5.3 ,  with the apparently conicting result that gears require material which is hard, tough and strong. By using thermo-chemical hardening processes it is possible to achieve these contradictory material properties, with the hardness, ductility and strength curveschanging gradually from the surface to the core of the work piece. Differentchemical compositions in the surface layer and in the core of the gear teeth allowthe creation of differentiated material conditions for tooth ank load capacity andbending strength.6.3 Heat Treatment 2 Several different diffusion processes can be used for this purpose, allowing the alloying elements to penetrate the base material under heat, and thus changing its composition and the associated properties. Apart from few niche applications, these processes require concentration gradients for the diffusion component and heating of the entire work piece. Figure 6.1 represents the relationship between residual and bending stresses. The residual stresses are shown along the ordinate. The dashed line (curve shows the residual stress curve, the dotted line (curve indicates the equivalent load- dependent stress, and curve 1 indicates the resulting cumulative stress in section -. It is evident that the compressive residual stresses induced by heat treatment reduce the tensile stresses in the root on the loaded side of the tooth. The form of such residual stress proles can be adjusted by the distribution of alloying ele

with the apparently conicting result that gears require material which is hard, tough and strong. By using thermo-chemical hardening processes it is possible to achieve these contradictory material properties, with the hardness, ductility and strength curveschanging gradually from the surface to the core of the work piece. Differentchemical compositions in the surface layer and in the core of the gear teeth allowthe creation of differentiated material conditions for tooth ank load capacity andbending strength.6.3 Heat Treatment 2 Several different diffusion processes can be used for this purpose, allowing the alloying elements to penetrate the base material under heat, and thus changing its composition and the associated properties. Apart from few niche applications, these processes require concentration gradients for the diffusion component and heating of the entire work piece. Figure 6.1 represents the relationship between residual and bending stresses. The residual stresses are shown along the ordinate. The dashed line (curve shows the residual stress curve, the dotted line (curve indicates the equivalent load- dependent stress, and curve 1 indicates the resulting cumulative stress in section -. It is evident that the compressive residual stresses induced by heat treatment reduce the tensile stresses in the root on the loaded side of the tooth. The form of such residual stress proles can be adjusted by the distribution of alloying ele| Model Type | Bevel-helical gearboxes B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 1880.000000 |

| Ratio Range | 1 : 12.5…71 |

| Low Speed Output | Solid shaft without parallel key |

| Nominal Torque | 63500 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | A. Friedr. Flender GmbH |

| Country of Manufacture | United States |

| Data Sheet & Drawings | B3CV-11-C th to th position see pages to Article No L Bevel-helical gearboxes B3 |