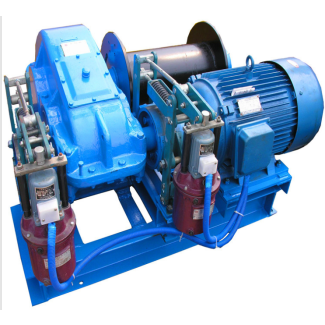

B3-CV12A rallel key HSV n A n A n On reque Bevel-helical gear reducers B3

In stock

SKU

B3-CV12A

$40,714.29

Flender/Flender Gear Units/Bevel-helical gear reducers B3

pening of the balanced feed gate allows the product to be spread evenly across the entire width of the feed gate. Thus an uniformly thick curtain of product feed is introduced to the nip of the grinding rolls. The rolls

gate. Thus an uniformly thick curtain of product feed is introduced to the nip of the grinding rolls. The rolls  rotate inward to provide the grinding action. The grinding gap is adjusted by turning the handwheel on both ends of

rotate inward to provide the grinding action. The grinding gap is adjusted by turning the handwheel on both ends of  the machine to ensure the gap is even. Thedesired gap is achieved by examining the ground stock underneath the rolls.

the machine to ensure the gap is even. Thedesired gap is achieved by examining the ground stock underneath the rolls.  The ground Grain-Milling Operations 2 material is dropped into the hopper below, where it is collected and picked up by pneu- matic lift that carries the ground material vertically up two or three oors higher to anair cyclone. Within the cyclone the material loses its velocity and begins to settle downat the bottom where it is discharged out through an airlock running underneath the cyclone. It is obvious that when intensive grinding is required the roll gap must be reduced. There are, however, other factors that intimately affect the grinding results and, therefore, the subsequent nished product quality. The following section on corrugation specica-tions provides some insight into the various technical aspects of the corrugations and theirrelation to the grinding results. 3.3.2 Corrugation Specications The following are the key factors that affect the grinding results by the corrugation proper- ties: Number of corrugation per centimeter Spiral of corrugationCorrugation proleDisposition of corrugation 3.3.2.1 Number of Corrugations The number of corrugations per centimeter increases when going down from rst break to the last break passage. This is because material to be ground becomes thinner as theprogression is made. If, for example, ner corrugations were used for grinding wheat in therst break, the combination of roll gap pressure required for grinding and higher number ofcorrugations would create lot of ne material, including cutting of the bran. On the other hand, ner corrugations are required for the latter break

The ground Grain-Milling Operations 2 material is dropped into the hopper below, where it is collected and picked up by pneu- matic lift that carries the ground material vertically up two or three oors higher to anair cyclone. Within the cyclone the material loses its velocity and begins to settle downat the bottom where it is discharged out through an airlock running underneath the cyclone. It is obvious that when intensive grinding is required the roll gap must be reduced. There are, however, other factors that intimately affect the grinding results and, therefore, the subsequent nished product quality. The following section on corrugation specica-tions provides some insight into the various technical aspects of the corrugations and theirrelation to the grinding results. 3.3.2 Corrugation Specications The following are the key factors that affect the grinding results by the corrugation proper- ties: Number of corrugation per centimeter Spiral of corrugationCorrugation proleDisposition of corrugation 3.3.2.1 Number of Corrugations The number of corrugations per centimeter increases when going down from rst break to the last break passage. This is because material to be ground becomes thinner as theprogression is made. If, for example, ner corrugations were used for grinding wheat in therst break, the combination of roll gap pressure required for grinding and higher number ofcorrugations would create lot of ne material, including cutting of the bran. On the other hand, ner corrugations are required for the latter break| Model Type | Bevel-helical gear reducers B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 1900.000000 |

| Ratio Range | 1 : 16…90 |

| Low Speed Output | Solid shaft without parallel key |

| Nominal Torque | 77200 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | Flender Guss Gmbh & Co. Kg |

| Country of Manufacture | Uruguay |

| Data Sheet & Drawings | B3-CV12A rallel key HSV n A n A n On reque Bevel-helical gear reducers B3 |