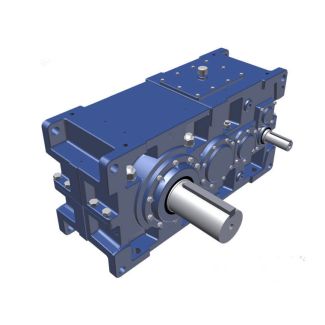

B3-VH-22B A n A Type Size D G l l kg Hollow shaft wi Bevel-helical speed reduction gearbox B3

In stock

SKU

B3-VH-22B

$212,142.86

Flender/Flender Gear Units/Bevel-helical speed reduction gearbox B3

ontact temperature uses the local parameters of load, radii of curvature, tangential speeds and coefcient of friction at each point on the tooth ank. For bevel gears, the cylindrical gear model used for the original approach can be transformed by

on the tooth ank. For bevel gears, the cylindrical gear model used for the original approach can be transformed by  converting the bevel gear tooth into nite tooth segments. The load variables are derived from the load distribution calculations in

converting the bevel gear tooth into nite tooth segments. The load variables are derived from the load distribution calculations in  Sect. 4.4.3.2 , the geometric and kinematic variables stem from the mathematical description of the tooth anks and the speed

Sect. 4.4.3.2 , the geometric and kinematic variables stem from the mathematical description of the tooth anks and the speed  of rotation. The local coefcient of friction is determined according to the current state of the art. Inuences like, for example pull or push sliding, are not taken into account. The instantaneous local contact temperature con iis formed as the sum of the temperature of the bevel gear teeth prior to engagement (bulk temperature ) and the maximum value of the temperature during the contact (ash temperature ). Unlike the methods described in Sect. 4.2.6 , this method determines the tempera- tures in discrete calculations for nite tooth segments of the respective contact lines. The required values, such as tangential speed and tooth surface curvatures, are determined for the individual calculation points, not on the basis of an approx- imate virtual cylindrical gear but exactly from the tooth ank geometry and kinematics. The contact temperature at the discrete point iis thus calculated on the basis of the previously calculated loads per unit face width and of locally determined inuence variables for each point, such as the coefcient of friction. Fig. 4.4 Tooth root stresses for bevel gear set1 4 Load Capacity and Efciency The analysis of discrete points ion the currently engaged contact lines yields the ash temperature distribution for one meshing position; repeating the process through the zone of action yields the complete scufng stress for tooth during one tooth engagement (Fig. 4.. If one rather assumes that mean value of the ash temperatures along the path of conta

of rotation. The local coefcient of friction is determined according to the current state of the art. Inuences like, for example pull or push sliding, are not taken into account. The instantaneous local contact temperature con iis formed as the sum of the temperature of the bevel gear teeth prior to engagement (bulk temperature ) and the maximum value of the temperature during the contact (ash temperature ). Unlike the methods described in Sect. 4.2.6 , this method determines the tempera- tures in discrete calculations for nite tooth segments of the respective contact lines. The required values, such as tangential speed and tooth surface curvatures, are determined for the individual calculation points, not on the basis of an approx- imate virtual cylindrical gear but exactly from the tooth ank geometry and kinematics. The contact temperature at the discrete point iis thus calculated on the basis of the previously calculated loads per unit face width and of locally determined inuence variables for each point, such as the coefcient of friction. Fig. 4.4 Tooth root stresses for bevel gear set1 4 Load Capacity and Efciency The analysis of discrete points ion the currently engaged contact lines yields the ash temperature distribution for one meshing position; repeating the process through the zone of action yields the complete scufng stress for tooth during one tooth engagement (Fig. 4.. If one rather assumes that mean value of the ash temperatures along the path of conta| Model Type | Bevel-helical speed reduction gearbox B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 9900.000000 |

| Ratio Range | 1 : 14…80 |

| Low Speed Output | Solid shaft with parallel key acc. to DIN 6885/1 with reinforced spigot |

| Nominal Torque | 470000 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Siemens Flender |

| Country of Manufacture | France |

| Data Sheet & Drawings | B3-VH-22B A n A Type Size D G l l kg Hollow shaft wi Bevel-helical speed reduction gearbox B3 |