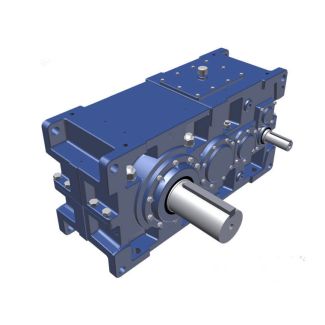

B3-VH-22-D n the shafts see Chapter Cooling options see Bevel-helical gear units B3

In stock

SKU

B3-VH-22-D

$212,142.86

Flender/Flender Gear Units/Bevel-helical gear units B3

ontamina-tion and operating parameters, includ-ing temperature and load. Micropitting starts with fatigue cracks on the surface (or just below the surface) of the gear teeth. These pits are caused by metal-to-metal con-tact of rough surfaces. But because cracks can form

surface) of the gear teeth. These pits are caused by metal-to-metal con-tact of rough surfaces. But because cracks can form  below the surface of the gear teeth, high-speed gears with smooth surfaces and good film thick-ness also can become pitted.

below the surface of the gear teeth, high-speed gears with smooth surfaces and good film thick-ness also can become pitted.  STLE-member Ravi Shah, staff engi- neer at Chevron, explains, ypically , lubrication in this equipment is under hydrodynamic or elastohydrodynamic

STLE-member Ravi Shah, staff engi- neer at Chevron, explains, ypically , lubrication in this equipment is under hydrodynamic or elastohydrodynamic  (EHD) regime. In the EHD regime, 2 FEBRUARY 2 TRIBOLOGY & LUBRICATION TECHNOLOGY Germany STLE.ORGTraiT of good gear oil* low viScoSiTy . As the lubricant travels through the filter system, contaminants, (which may originate outside the system or result from inside wear) should be removed. Slow-moving, highly viscous lubricants can be difficult to filter. They can cause pressure at the filter to increase. If sufficiently high, it will trigger system bypass and allow contaminant-laden lubricant to circumvent the filters. Less viscous lubricants flow more easily through the filtration system where contaminants are effectively removed. This reduces the likelihood of machinery damage and increases equipment life. Another benefit of using lower viscosity gear oil is that it may not need to be changed as often, resulting in less costly downtime. Industrial gears operating under heavy loads require extreme-pressure protection for gear components, but mainstream industrial gear oils do not always provide high extreme-pressure performance at low viscosity grades. This means that not just any low viscosity fluid will perform well. durabiliTy . Industrial gear oils formulated for extended durability keep gears operating correctly and protect equipment by prolong-ing life, minimizing downtime, maximizing productivity and reducing maintenance costs.deMulSibiliTy . Water can get into the system (especially the reservoir) in many ways,

(EHD) regime. In the EHD regime, 2 FEBRUARY 2 TRIBOLOGY & LUBRICATION TECHNOLOGY Germany STLE.ORGTraiT of good gear oil* low viScoSiTy . As the lubricant travels through the filter system, contaminants, (which may originate outside the system or result from inside wear) should be removed. Slow-moving, highly viscous lubricants can be difficult to filter. They can cause pressure at the filter to increase. If sufficiently high, it will trigger system bypass and allow contaminant-laden lubricant to circumvent the filters. Less viscous lubricants flow more easily through the filtration system where contaminants are effectively removed. This reduces the likelihood of machinery damage and increases equipment life. Another benefit of using lower viscosity gear oil is that it may not need to be changed as often, resulting in less costly downtime. Industrial gears operating under heavy loads require extreme-pressure protection for gear components, but mainstream industrial gear oils do not always provide high extreme-pressure performance at low viscosity grades. This means that not just any low viscosity fluid will perform well. durabiliTy . Industrial gear oils formulated for extended durability keep gears operating correctly and protect equipment by prolong-ing life, minimizing downtime, maximizing productivity and reducing maintenance costs.deMulSibiliTy . Water can get into the system (especially the reservoir) in many ways,| Model Type | Bevel-helical gear units B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 9900.000000 |

| Ratio Range | 1 : 14…80 |

| Low Speed Output | Solid shaft with parallel key acc. to DIN 6885/1 with reinforced spigot |

| Nominal Torque | 470000 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Siemens AG |

| Country of Manufacture | Georgia |

| Data Sheet & Drawings | B3-VH-22-D n the shafts see Chapter Cooling options see Bevel-helical gear units B3 |