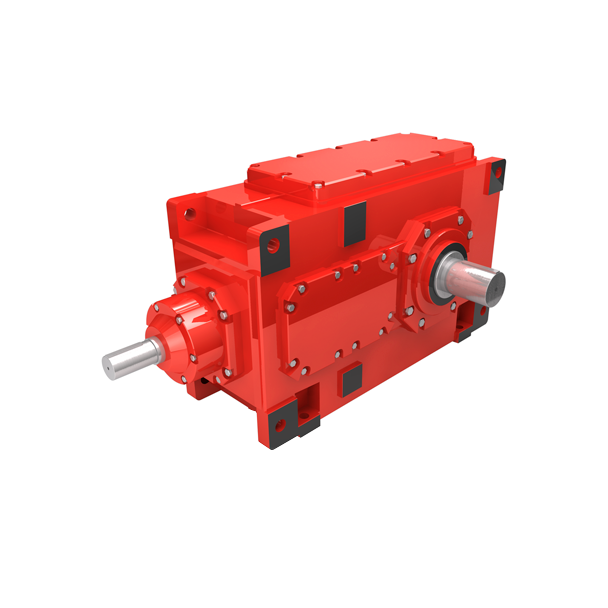

B3-VH-23-A page onwards Approximate values exact data acc Bevel-helical gearboxes B3

In stock

SKU

B3-VH-23-A

$257,142.86

Flender/Flender Gear Units/Bevel-helical gearboxes B3

ontents lead to higher amounts of retainedaustenite preventing further hardness increase. Hardenability is specic property of various steels. It is inuenced by different alloy compositions. distinction is drawn between hardness increase and hardness penetration. The rst depends mainly on the

inuenced by different alloy compositions. distinction is drawn between hardness increase and hardness penetration. The rst depends mainly on the  carbon content, the second on the additional alloying components in the steel.6.3 Heat Treatment 2 Tempering at low temperatures has

carbon content, the second on the additional alloying components in the steel.6.3 Heat Treatment 2 Tempering at low temperatures has  proved useful after martensitic transforma- tion. It reduces the brittleness of the material and reduces the risk of crack initiation.The

proved useful after martensitic transforma- tion. It reduces the brittleness of the material and reduces the risk of crack initiation.The  process sequence for hardening thus generally consists of the steps austenitizing, quenching with martensite formation and tempering [ SIZ0 ], [GIES0 ]. 6.3.2 Heat Treatment Processes Heat treatments can be differentiated between thermal and thermo-chemical pro- cesses, as listed in Table 6.2. Thermal processes require suitable hardenability of the base material. Depending on the temperature prole, surface hardening or through hardening are possible. Only certain alloying systems are suitable for through hardening. Hard- ening the entire cross-section of the component is in any case an exception in gears.In practice, induction and ame hardening are relevant, along with laser hardening.These processes are characterized by relatively light equipment, simple operationand high output. In the case of thermo-chemical processes, the chemical composition of the material in the surface layer can be designed according to the stress prole of thegears, such as wear resistance on the surface and toughness in the core. The wear resistance on the surface is achieved by hardening; the strength and toughness of the core by using suitable alloy composition. 6.3.3 Thermal Processes 6.3.3.1 Induction Hardening The heat is generated in the material by means of AC induction at different frequencies. The frequency of the eddy current and the distance of the inductorfrom the surface determine the depth of penetration and hence the a

process sequence for hardening thus generally consists of the steps austenitizing, quenching with martensite formation and tempering [ SIZ0 ], [GIES0 ]. 6.3.2 Heat Treatment Processes Heat treatments can be differentiated between thermal and thermo-chemical pro- cesses, as listed in Table 6.2. Thermal processes require suitable hardenability of the base material. Depending on the temperature prole, surface hardening or through hardening are possible. Only certain alloying systems are suitable for through hardening. Hard- ening the entire cross-section of the component is in any case an exception in gears.In practice, induction and ame hardening are relevant, along with laser hardening.These processes are characterized by relatively light equipment, simple operationand high output. In the case of thermo-chemical processes, the chemical composition of the material in the surface layer can be designed according to the stress prole of thegears, such as wear resistance on the surface and toughness in the core. The wear resistance on the surface is achieved by hardening; the strength and toughness of the core by using suitable alloy composition. 6.3.3 Thermal Processes 6.3.3.1 Induction Hardening The heat is generated in the material by means of AC induction at different frequencies. The frequency of the eddy current and the distance of the inductorfrom the surface determine the depth of penetration and hence the a| Model Type | Bevel-helical gearboxes B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 12000.000000 |

| Ratio Range | 1 : 20…71 |

| Low Speed Output | Solid shaft with parallel key acc. to DIN 6885/1 with reinforced spigot |

| Nominal Torque | 640000 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | FLENDER TÜBINGEN GMBH |

| Country of Manufacture | Germany |

| Data Sheet & Drawings | B3-VH-23-A page onwards Approximate values exact data acc Bevel-helical gearboxes B3 |