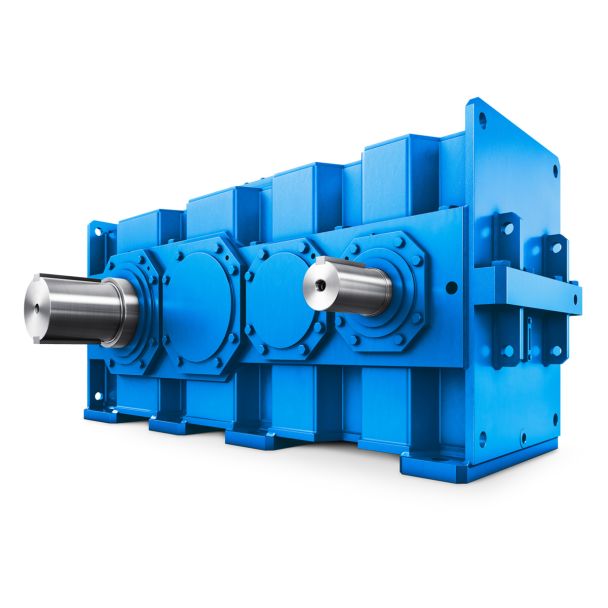

B3-VH-21-A p lubrica tionOil quantity H V with forced l Bevel-helical gear unit B3

In stock

SKU

B3-VH-21-A

$197,142.86

Flender/Flender Gear Units/Bevel-helical gear unit B3

ons, mills cannot run throughout the year. few mills, therefore, haveswitched over to mechanical hot-airdrying systems. Most of the dryers in use are of thebatch-type bin drier, with holding capacity of 1 tonnes. These dryers use diesel, fur- nace oil,

in use are of thebatch-type bin drier, with holding capacity of 1 tonnes. These dryers use diesel, fur- nace oil,  dry farm wastes, and groundnut husk as fuel. 2.3.9 Splitting Machines The nal product of the pulse-milling industry is the

dry farm wastes, and groundnut husk as fuel. 2.3.9 Splitting Machines The nal product of the pulse-milling industry is the  dehusked split cotyledon, popularly known as dhal in milling sector and consumers in the Indian subcontinent. During pro- Milling of

dehusked split cotyledon, popularly known as dhal in milling sector and consumers in the Indian subcontinent. During pro- Milling of  Pulses 4 cessing mixture of dehusked and unhusked grains is obtained. Fully dehusked, unsplit grains are known in the industry as gota and are split in two after water treatment and sun-drying. In some pulses such as black gram, the gota is split without any treatment.For splitting, various machines similar to the under-runner disk (URD) shellers, verticalor horizontal attrition mills, roller machines, or impact machines are used. In few mills, just dropping the dehusked whole grains on hard surface from the discharge end of an elevator is also adapted for splitting. The splitting roller is generally similar to the dehusking roller. However, the size of the emery grits (which reects the smoothness or roughness of rollers) varies frompulse to pulse. An impact-type machine is very commonly used for splitting the dehuskedgrains although, in some places in India, only roller machines are used. Vertical or horizon- tal grinders or URD shelters are generally used for splitting chickpea, whereas gota from black gram is split using attrition mills. 2.3.1 Aspiration SystemsA box-type aspirator with suction fan is generally used for separation of husk and pow- der. Brokens are separated by appropriate sieves, which are mixed later with husk and powder and sold as cattle feed. Cyclone-type separating systems are being introduced in few pulse mills in India for improving efciency and to reduce dust pollution. 2.3.1 Splits and Whole Grain SeparatorsThese machines are simil

Pulses 4 cessing mixture of dehusked and unhusked grains is obtained. Fully dehusked, unsplit grains are known in the industry as gota and are split in two after water treatment and sun-drying. In some pulses such as black gram, the gota is split without any treatment.For splitting, various machines similar to the under-runner disk (URD) shellers, verticalor horizontal attrition mills, roller machines, or impact machines are used. In few mills, just dropping the dehusked whole grains on hard surface from the discharge end of an elevator is also adapted for splitting. The splitting roller is generally similar to the dehusking roller. However, the size of the emery grits (which reects the smoothness or roughness of rollers) varies frompulse to pulse. An impact-type machine is very commonly used for splitting the dehuskedgrains although, in some places in India, only roller machines are used. Vertical or horizon- tal grinders or URD shelters are generally used for splitting chickpea, whereas gota from black gram is split using attrition mills. 2.3.1 Aspiration SystemsA box-type aspirator with suction fan is generally used for separation of husk and pow- der. Brokens are separated by appropriate sieves, which are mixed later with husk and powder and sold as cattle feed. Cyclone-type separating systems are being introduced in few pulse mills in India for improving efciency and to reduce dust pollution. 2.3.1 Splits and Whole Grain SeparatorsThese machines are simil| Model Type | Bevel-helical gear unit B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 9200.000000 |

| Ratio Range | 1 : 12.5…71 |

| Low Speed Output | Solid shaft with parallel key acc. to DIN 6885/1 with reinforced spigot |

| Nominal Torque | 420000 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Flender Guss Gmbh & Co. Kg |

| Country of Manufacture | El Salvador |

| Data Sheet & Drawings | B3-VH-21-A p lubrica tionOil quantity H V with forced l Bevel-helical gear unit B3 |