B3-VH-18B afts see Chapter Flangemounted pump not in conn Bevel-helical gear reducer B3

In stock

SKU

B3-VH-18B

$117,750.00

Flender/Flender Gear Units/Bevel-helical gear reducer B3

only. The unit is complete mounted and chec ked acc. DIN EN and VDE norms. Technical Data : Preparation capacity: max. 7 / function from emulsion concentration Concentration: from 0,1% to 0,5% Test certificates, any other communication mode, wooden packing

max. 7 / function from emulsion concentration Concentration: from 0,1% to 0,5% Test certificates, any other communication mode, wooden packing  on request and charged extra. Max. visc osity: 2 mPas Water inlet connection: DN1 Water flow: 1 /, 3,5 bar

on request and charged extra. Max. visc osity: 2 mPas Water inlet connection: DN1 Water flow: 1 /, 3,5 bar  Product outlet connection: DN3 Power supply: 4V - 5Hz, 3ph//PE (P Connection power: 0,3 kW Nominal current: 2A Motor protection:

Product outlet connection: DN3 Power supply: 4V - 5Hz, 3ph//PE (P Connection power: 0,3 kW Nominal current: 2A Motor protection:  IP5, Iso. Kl. Communication The unit cons ists basically of: 1 tank in 2 parts made from PP with agitator rails Inspection holes for the tank Solution dosing line with ball valve and over flow connection and drain directly erected on the tank Dosing pump for concentrated liquid polymer solution (=emulsion), type DDA with max. dosing flow of 7,5 / in slowmode 2%, erected and connected to preparation control cabinet. Power supply: 2V - 5Hz Connection power: 1 Set 1 ANNEX 1 . Technical Specifications PN 1.1.0 -0.3 3 | Low speed agitator, mounted on preparation chamber, with 2 pro pellers in stainless steel V4A. Power supply: 4V - 5Hz Connection power: 0,2 kW Nominal current: 0,6A Agitator speed: 3 tr/min Water unit (material: brass) is mounted of the tank, including: 1 shut -off valve, 1 pressure reduction valve with di rt trap and manometer, 1 solenoid valve (2VDC, approx. 1 ), 1 vortex water flow meter (signal 4 -2 mA) 1 ultra -sonic sensor for continuous level measuring (2VDC, output signal: 4 -2mA) Control cabinet Including 1 PLC and color operator panel or easy control of the plant. Free potentiel contacts (C0) are available for: main fault 2. dry run 3. lack of liquid polymer Selected language for display: multilingual operating surface (German, English, French). English language is defined as start language. The tank of concentrated polymer solution (=emulsion) has to be installed cl

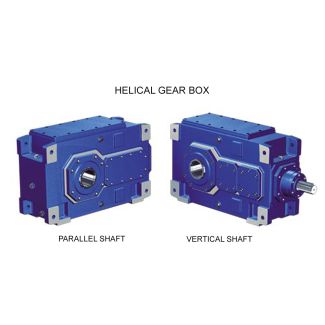

IP5, Iso. Kl. Communication The unit cons ists basically of: 1 tank in 2 parts made from PP with agitator rails Inspection holes for the tank Solution dosing line with ball valve and over flow connection and drain directly erected on the tank Dosing pump for concentrated liquid polymer solution (=emulsion), type DDA with max. dosing flow of 7,5 / in slowmode 2%, erected and connected to preparation control cabinet. Power supply: 2V - 5Hz Connection power: 1 Set 1 ANNEX 1 . Technical Specifications PN 1.1.0 -0.3 3 | Low speed agitator, mounted on preparation chamber, with 2 pro pellers in stainless steel V4A. Power supply: 4V - 5Hz Connection power: 0,2 kW Nominal current: 0,6A Agitator speed: 3 tr/min Water unit (material: brass) is mounted of the tank, including: 1 shut -off valve, 1 pressure reduction valve with di rt trap and manometer, 1 solenoid valve (2VDC, approx. 1 ), 1 vortex water flow meter (signal 4 -2 mA) 1 ultra -sonic sensor for continuous level measuring (2VDC, output signal: 4 -2mA) Control cabinet Including 1 PLC and color operator panel or easy control of the plant. Free potentiel contacts (C0) are available for: main fault 2. dry run 3. lack of liquid polymer Selected language for display: multilingual operating surface (German, English, French). English language is defined as start language. The tank of concentrated polymer solution (=emulsion) has to be installed cl| Model Type | Bevel-helical gear reducer B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 5495.000000 |

| Ratio Range | 1 : 14…80 |

| Low Speed Output | Solid shaft with parallel key acc. to DIN 6885/1 with reinforced spigot |

| Nominal Torque | 240000 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Flender GmbH |

| Country of Manufacture | Germany |

| Data Sheet & Drawings | B3-VH-18B afts see Chapter Flangemounted pump not in conn Bevel-helical gear reducer B3 |