B3VH-18-C ection with versions G H and I For forced lubric Bevel-helical speed reducer B3

In stock

SKU

B3VH-18-C

$117,750.00

Flender/Flender Gear Units/Bevel-helical speed reducer B3

onmental protection, process technologies need to be developed which reduce losses due to spray mist, .. which increase coating effi- ciency. The coating efficiency of the spraying methods used in industrial and commercial painting technolo currently shows wide range of

ciency. The coating efficiency of the spraying methods used in industrial and commercial painting technolo currently shows wide range of  variation,sometimeswith extremely lowvalues. In individuaqcases, spray losses as high as 8% and more have been recorded with workpiece geometries which

variation,sometimeswith extremely lowvalues. In individuaqcases, spray losses as high as 8% and more have been recorded with workpiece geometries which  are unfavourablefrom the standpoint of spray technology (filigreed) or with poorly set and contralled spray parameters. This considerable environmental burden

are unfavourablefrom the standpoint of spray technology (filigreed) or with poorly set and contralled spray parameters. This considerable environmental burden  or the complex methods of collecting and disposing of paint droplets,as well as paint consumption itself, can be greatlyreducedthrough the objec- tive control and monitoring of the spray jet characteristics. Process technology offers consider- able room for play in improving coating efficiency. Strategies for objective adaptation of the spray jet to the application conditions and continuous monitoring of the spray jet characteristics were to be developed within the framework of this project. 2. Working steps Suitable measurement and control methods were to be illustrated within the framework of flexible work plan: - Determination of the functional dependence of technical processing parameters of selected spraying systems on spray losses and coating quality. The measures required to minimise spray losses while maintaining aconstant coating qualitywere to be illustrated and assessed using examples. - Determination of measurement principles for automatic monitorin of the spray jet, and assessment of their value and practical applicability in conjunction wi8 changes or malfunc- tions in operations and/or equipment. 7 ___- 3. Results The results of the studies indicate the technical processing options for relieving the burden on the environment during spray painting The functional dependences of the process control parameters determined for compressed- air spraying a

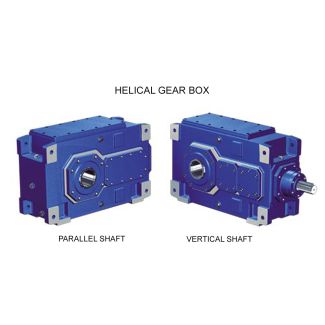

or the complex methods of collecting and disposing of paint droplets,as well as paint consumption itself, can be greatlyreducedthrough the objec- tive control and monitoring of the spray jet characteristics. Process technology offers consider- able room for play in improving coating efficiency. Strategies for objective adaptation of the spray jet to the application conditions and continuous monitoring of the spray jet characteristics were to be developed within the framework of this project. 2. Working steps Suitable measurement and control methods were to be illustrated within the framework of flexible work plan: - Determination of the functional dependence of technical processing parameters of selected spraying systems on spray losses and coating quality. The measures required to minimise spray losses while maintaining aconstant coating qualitywere to be illustrated and assessed using examples. - Determination of measurement principles for automatic monitorin of the spray jet, and assessment of their value and practical applicability in conjunction wi8 changes or malfunc- tions in operations and/or equipment. 7 ___- 3. Results The results of the studies indicate the technical processing options for relieving the burden on the environment during spray painting The functional dependences of the process control parameters determined for compressed- air spraying a| Model Type | Bevel-helical speed reducer B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 5495.000000 |

| Ratio Range | 1 : 14…80 |

| Low Speed Output | Solid shaft with parallel key acc. to DIN 6885/1 with reinforced spigot |

| Nominal Torque | 240000 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Siemens Industriegetriebe GmbH |

| Country of Manufacture | Germany |

| Data Sheet & Drawings | B3VH-18-C ection with versions G H and I For forced lubric Bevel-helical speed reducer B3 |