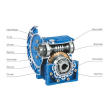

ensions Twostage gear unit sizes to Twostage B3-VH-12B Bevel-helical gear units B3

In stock

SKU

B3-VH-12B

$40,714.29

Flender/Flender Gear Units/Bevel-helical gear units B3

on, 1. 1. Siegel , Fawcett . Food legume processing and utilization. IRDC-TSI. International Devel- opment Research Centre, Ottawa, Canada, 1. 1. Erskine WI, Williams PC, Nakkoul . Splitting and dehulling lentil ( Lens culinaris ): effects of seed size

1. 1. Erskine WI, Williams PC, Nakkoul . Splitting and dehulling lentil ( Lens culinaris ): effects of seed size  and different pretreatments. Sci Food Agric 1, 5:7. 1. Ehiwe AOF, Reichert RD, Schwab DJ, Humbert ES, Mazza . Effect

and different pretreatments. Sci Food Agric 1, 5:7. 1. Ehiwe AOF, Reichert RD, Schwab DJ, Humbert ES, Mazza . Effect  of seed moisture content and temperature on the seed coat durability of eld pea. Cereal Chem 1; 6:2. 1. Dorrel

of seed moisture content and temperature on the seed coat durability of eld pea. Cereal Chem 1; 6:2. 1. Dorrel  DG. Seedcoat damage in navy beans ( Phaseolus vulgaris .) induced by mechanical abuse. Ph dissertation. Michigan State University, East Lansing, MI, 1. 1. Mazza , Campbell CG. Inuence of water activity and temperature on dehulling of buck- wheat. Cereal Chem 1; 6:3. 1a. Shyeh JB, Rodda ED, Nelson AI. Evaluation of new soybean dehuller. Trans ASAE 1; 2:5. 1. Galloway JP. Cleaning, cracking dehulling decorticating and aking of oil-bearing materials. Am Oil Chem Soc 1; 5:2. 1. Sahay KM, Bisht BS. Development of small abrasive cylindrical mill for milling pulses. Int Food Sci Technol 1; 2:1. 1. Sahay KM, Bisht BS. Optimization of grades of Carborundum for best recovery of dhal in milling of different pulses. Agric Eng Today 1; 1(:1,2. 1. Reichert RD, Oomah BD, Youngs CG. Factors affecting the efciency of abrasive-type dehul- ling of grain legumes investigated with new intermediate-sized, batch dehuller. Food Sci1 4:2. 1. Schule-Technical literature on verti sheller and splitter for pulses. 1 FH Schule Muhlenbau GmbH, Dieselstrasse 5, -2, Reinbek, Hamburg, . 2. Kurien PP, Patil BS. hand operated small scale pulse dehusking machine for rural use. Res Ind 1; 3:2. 2. Kurien PP, Shri PS, Balakrishnan. Dhal processing technology by CFTRI: boon to pulse growers and processors. Fusion Asia 1:3. 2. Separating the hulls from the groats. Res Dev Bull 1; 9:1.2. Moser DP, Fielke JM. Evaluation of grain legume decorticating machinery. Agricultural Ma- chinery Research and Design Center, School of Manu

DG. Seedcoat damage in navy beans ( Phaseolus vulgaris .) induced by mechanical abuse. Ph dissertation. Michigan State University, East Lansing, MI, 1. 1. Mazza , Campbell CG. Inuence of water activity and temperature on dehulling of buck- wheat. Cereal Chem 1; 6:3. 1a. Shyeh JB, Rodda ED, Nelson AI. Evaluation of new soybean dehuller. Trans ASAE 1; 2:5. 1. Galloway JP. Cleaning, cracking dehulling decorticating and aking of oil-bearing materials. Am Oil Chem Soc 1; 5:2. 1. Sahay KM, Bisht BS. Development of small abrasive cylindrical mill for milling pulses. Int Food Sci Technol 1; 2:1. 1. Sahay KM, Bisht BS. Optimization of grades of Carborundum for best recovery of dhal in milling of different pulses. Agric Eng Today 1; 1(:1,2. 1. Reichert RD, Oomah BD, Youngs CG. Factors affecting the efciency of abrasive-type dehul- ling of grain legumes investigated with new intermediate-sized, batch dehuller. Food Sci1 4:2. 1. Schule-Technical literature on verti sheller and splitter for pulses. 1 FH Schule Muhlenbau GmbH, Dieselstrasse 5, -2, Reinbek, Hamburg, . 2. Kurien PP, Patil BS. hand operated small scale pulse dehusking machine for rural use. Res Ind 1; 3:2. 2. Kurien PP, Shri PS, Balakrishnan. Dhal processing technology by CFTRI: boon to pulse growers and processors. Fusion Asia 1:3. 2. Separating the hulls from the groats. Res Dev Bull 1; 9:1.2. Moser DP, Fielke JM. Evaluation of grain legume decorticating machinery. Agricultural Ma- chinery Research and Design Center, School of Manu| Model Type | Bevel-helical gear units B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 1900.000000 |

| Ratio Range | 1 : 16…90 |

| Low Speed Output | Solid shaft with parallel key acc. to DIN 6885/1 with reinforced spigot |

| Nominal Torque | 77200 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | FLENDER GRAFFENSTADEN |

| Country of Manufacture | Austria |

| Data Sheet & Drawings | ensions Twostage gear unit sizes to Twostage B3-VH-12B Bevel-helical gear units B3 |