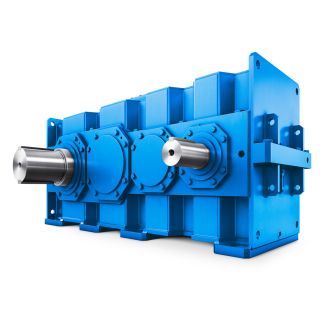

Bevel-helical gearboxes B3 shafts The slow speed hollow shaft H hollow shaf B3-KV7A

In stock

SKU

B3-KV7A

$15,000.00

Flender/Flender Gear Units/Bevel-helical gearboxes B3

ry compres sed air, wherever water flushing is not desirable to clean the pipe of all dirt, debris or loose foreign materials. Required pressure of water, flushing shall meet the fire hydr ant pressure or utility water pressure. For air

foreign materials. Required pressure of water, flushing shall meet the fire hydr ant pressure or utility water pressure. For air  flushing the line, system will be pressurised by compressed air at the required pressure which shall be 5 psi maximum.

flushing the line, system will be pressurised by compressed air at the required pressure which shall be 5 psi maximum.  The pressure shall then be released by quick opening of valve, already in the line for this purpose. This procedure

The pressure shall then be released by quick opening of valve, already in the line for this purpose. This procedure  shall be repeated as many times as required till the inside of the pipe is fully cleaned. In line instruments like control valves, orifice plates, rota meters, safety valves and other instruments like thermowells which may interfere with flushing shall not be included the flushing circuit. 1 of 1 STANDARD TECHNICAL SPECIFICATION MECON LIMITED REGD. OFF: RANCHI 8 OIL & GAS SBU, DELHI DOCUMENT NO. Page 2 of 8 TITLE MEC//0/2/1 REVISION : 0 FLUSHING AND TESTING OF PIPING SYSTEMS EDITION : 1 From all permanent strainers the screens/meshes shall be remo ved before flushing. Screens/meshes shall be re- installed after flushing but before testing. During flushing temporary strainers shall be retained. These shall be removed, cleaned and reinstalled afte flushing, but, before testing. In case an equipment such as column, vessel, exchanger etc. forms part of piping circuit during flushing, this shall be done with the approval of Engineer- in - Charge. However equipment thus included in the circuit, shall be completely cleaned and dried with comprss4ed air, after flushing is completed. During flushing discharged water/air shall be drained at the place directed the Engineer- in - Charge. If necessary, proper temporary drainage shall be provided by the contractor. Care shall be taken during flushing so as not to damage/spoil work of other agencies. Precautions shall also be taken to prevent entry of water/foreign matter into equipment, electric motors, instruments, elec

shall be repeated as many times as required till the inside of the pipe is fully cleaned. In line instruments like control valves, orifice plates, rota meters, safety valves and other instruments like thermowells which may interfere with flushing shall not be included the flushing circuit. 1 of 1 STANDARD TECHNICAL SPECIFICATION MECON LIMITED REGD. OFF: RANCHI 8 OIL & GAS SBU, DELHI DOCUMENT NO. Page 2 of 8 TITLE MEC//0/2/1 REVISION : 0 FLUSHING AND TESTING OF PIPING SYSTEMS EDITION : 1 From all permanent strainers the screens/meshes shall be remo ved before flushing. Screens/meshes shall be re- installed after flushing but before testing. During flushing temporary strainers shall be retained. These shall be removed, cleaned and reinstalled afte flushing, but, before testing. In case an equipment such as column, vessel, exchanger etc. forms part of piping circuit during flushing, this shall be done with the approval of Engineer- in - Charge. However equipment thus included in the circuit, shall be completely cleaned and dried with comprss4ed air, after flushing is completed. During flushing discharged water/air shall be drained at the place directed the Engineer- in - Charge. If necessary, proper temporary drainage shall be provided by the contractor. Care shall be taken during flushing so as not to damage/spoil work of other agencies. Precautions shall also be taken to prevent entry of water/foreign matter into equipment, electric motors, instruments, elec| Model Type | Bevel-helical gearboxes B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 700.000000 |

| Ratio Range | 1 : 12.5…71 |

| Low Speed Output | Hollow shaft with spline acc. to DIN 5480 |

| Nominal Torque | 21700 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | Flender GmbH |

| Country of Manufacture | Mongolia |

| Data Sheet & Drawings | Bevel-helical gearboxes B3 shafts The slow speed hollow shaft H hollow shaf B3-KV7A |