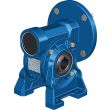

Bevel-helical speed reduction gearboxes B3 stops and dimension G see page onwards Backst B3-KV-8-A

In stock

SKU

B3-KV-8-A

$17,142.86

Flender/Flender Gear Units/Bevel-helical speed reduction gearboxes B3

ry. The goal is to get grip on consumption costs and stillstands, and to eliminate idle periods. It is also im- portant to know exactly what ton of produced material in the desired quality costs also with the associated costs

im- portant to know exactly what ton of produced material in the desired quality costs also with the associated costs  calculated in. Ma-estro offers suite of individual solutions with which quarry can monitor, control and regulate its production. -Production, for

calculated in. Ma-estro offers suite of individual solutions with which quarry can monitor, control and regulate its production. -Production, for  example, provides an overview of production and energy use in quarry and its auxiliary In quarries it is necessary to

example, provides an overview of production and energy use in quarry and its auxiliary In quarries it is necessary to  have good over - view of energy use and costs. However, many areas are not yet automated. Thanks to part- nership between Siemens and Ma-estro, that is about to change. Partnership between Ma-estro Srl and Siemens Technology squared 5MineralsFocus 2/2 | Cement 5Cement | MineralsFocus 2/2 works; -Control helps control opera- tions; -Maintenance provides assistance with managing maintenance; -Fuel observes and controls fuel use; and -Transport is control system for the loading of material, which, along with the necessary transport and delivery doc- umentation, also ensures material trace- ability. Via dashboard, quarry operators have full control of all important data to calculate production costs in real time. Ma-estro was founded seven years ago. The company sees itself as provider of products as well as solutions. The perma-nent monitoring of plants, coupled with the ability to access at any time respective documentation and inventory information, simplifies the organization of construction sites and quarries, says Giorgio Manara. Measurable cost savings are possible with our products. Most important is informa-tion about the actual costs of each ton of produced stone, adds Ma-estros owner and founder. Our system pays for itself within year, which is particularly impor - tant for many companies in these times of financial and economic crises. In connection with Siemens devices and systems, the Ma-estro systems have also been used for processing plan

have good over - view of energy use and costs. However, many areas are not yet automated. Thanks to part- nership between Siemens and Ma-estro, that is about to change. Partnership between Ma-estro Srl and Siemens Technology squared 5MineralsFocus 2/2 | Cement 5Cement | MineralsFocus 2/2 works; -Control helps control opera- tions; -Maintenance provides assistance with managing maintenance; -Fuel observes and controls fuel use; and -Transport is control system for the loading of material, which, along with the necessary transport and delivery doc- umentation, also ensures material trace- ability. Via dashboard, quarry operators have full control of all important data to calculate production costs in real time. Ma-estro was founded seven years ago. The company sees itself as provider of products as well as solutions. The perma-nent monitoring of plants, coupled with the ability to access at any time respective documentation and inventory information, simplifies the organization of construction sites and quarries, says Giorgio Manara. Measurable cost savings are possible with our products. Most important is informa-tion about the actual costs of each ton of produced stone, adds Ma-estros owner and founder. Our system pays for itself within year, which is particularly impor - tant for many companies in these times of financial and economic crises. In connection with Siemens devices and systems, the Ma-estro systems have also been used for processing plan| Model Type | Bevel-helical speed reduction gearboxes B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 800.000000 |

| Ratio Range | 1 : 16…90 |

| Low Speed Output | Hollow shaft with spline acc. to DIN 5480 |

| Nominal Torque | 27200 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | Flender Siemens |

| Country of Manufacture | Nauru |

| Data Sheet & Drawings | Bevel-helical speed reduction gearboxes B3 stops and dimension G see page onwards Backst B3-KV-8-A |