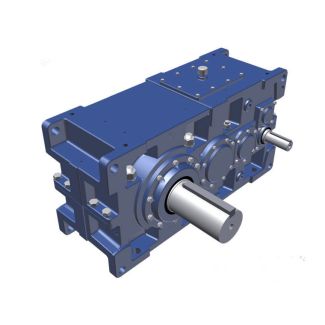

B3-KV-28-A lender MD Bevel helical gear units vertical mou Bevel-helical gearboxes B3

In stock

SKU

B3-KV-28-A

$550,714.29

Flender/Flender Gear Units/Bevel-helical gearboxes B3

s of micropitting, he says. It is often talked about in re-lation to the wind turbine industry , but we see it in many other applica-tions, too. In some cases, micropitting may lessen over time, while in others it can

see it in many other applica-tions, too. In some cases, micropitting may lessen over time, while in others it can  ultimately lead to vibration, noise or even more destructive phe-nomena such as macropitting. HeAT When it comes to heat-related issues,

ultimately lead to vibration, noise or even more destructive phe-nomena such as macropitting. HeAT When it comes to heat-related issues,  gear oil serves two functions: it re-moves heat in the machinery generat-ed by friction, and it protects itself from viscosity

gear oil serves two functions: it re-moves heat in the machinery generat-ed by friction, and it protects itself from viscosity  breakdown due to heat. The viscosity of lubricant decreases as the temperature increases. So the viscosity of the oil must be high enough to provide an adequate lubri-cating fi lm but not so high that it cre-ates friction within the fi lm itself. With the constant pressure to in- crease operating loads, gearboxes are burdened with increasingly hotter op-erating temperatures. As result, im-proved thermal stability in gear lubri-cants is an imperative. Todays gear oils need to be formulated to with-stand the entire temperature range that the gear could be exposed to (both within the system and in the ambient environment). This will not only help to maximize the life of the gear oil but also of the gears themselves. WATeR cOnTAMInATIOn Contamination is key interest for some industrial cus-tomers, says Nelson Tam, Lubrizols in-dustrial product man-ager for ROA (Rest of Asia). Their most com-mon problem is foaming and lowering of demulsibility performance. Contamination is most common in gearboxes in ce-ment plants and plants that handle coalsuch as coal mines and coal-fi red power plants. Shah adds that contamination also can occur in the proximity of sea/wa-ter sources and where the tempera-tures vary signifi cantly between day-time and nighttime. Abrasive dust particles can pene- trate the oil fi lm and cause surface dis-tortion and wear. Water contamina-tion can rust gear surfaces and, in the extreme, destroy the gear completely . Consider that just 1% of water in an industria

breakdown due to heat. The viscosity of lubricant decreases as the temperature increases. So the viscosity of the oil must be high enough to provide an adequate lubri-cating fi lm but not so high that it cre-ates friction within the fi lm itself. With the constant pressure to in- crease operating loads, gearboxes are burdened with increasingly hotter op-erating temperatures. As result, im-proved thermal stability in gear lubri-cants is an imperative. Todays gear oils need to be formulated to with-stand the entire temperature range that the gear could be exposed to (both within the system and in the ambient environment). This will not only help to maximize the life of the gear oil but also of the gears themselves. WATeR cOnTAMInATIOn Contamination is key interest for some industrial cus-tomers, says Nelson Tam, Lubrizols in-dustrial product man-ager for ROA (Rest of Asia). Their most com-mon problem is foaming and lowering of demulsibility performance. Contamination is most common in gearboxes in ce-ment plants and plants that handle coalsuch as coal mines and coal-fi red power plants. Shah adds that contamination also can occur in the proximity of sea/wa-ter sources and where the tempera-tures vary signifi cantly between day-time and nighttime. Abrasive dust particles can pene- trate the oil fi lm and cause surface dis-tortion and wear. Water contamina-tion can rust gear surfaces and, in the extreme, destroy the gear completely . Consider that just 1% of water in an industria| Model Type | Bevel-helical gearboxes B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 25700.000000 |

| Ratio Range | 1 : 22.4…80 |

| Low Speed Output | Hollow shaft with spline acc. to DIN 5480 |

| Nominal Torque | 1400000 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | Siemens AG |

| Country of Manufacture | Belarus |

| Data Sheet & Drawings | B3-KV-28-A lender MD Bevel helical gear units vertical mou Bevel-helical gearboxes B3 |