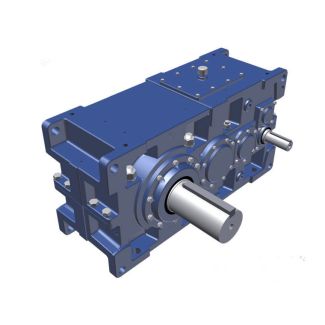

B3-KV28-B nting position Type B Gear unit dimensions twosta Bevel-helical gear boxes B3

In stock

SKU

B3-KV28-B

$550,714.29

Flender/Flender Gear Units/Bevel-helical gear boxes B3

s of penetration, stability, damping, assembly, accessibility etc. Modern 6-axis CNC machines may be fundamentally different from earlier pure mechanical ones or NC models, but their relative generating motion is identical. The tool is guided using three translations and three

ones or NC models, but their relative generating motion is identical. The tool is guided using three translations and three  rotations, thus total of six axes in relation to the work piece. Fig. 3.6 Conical generating gear for the non-generating

rotations, thus total of six axes in relation to the work piece. Fig. 3.6 Conical generating gear for the non-generating  method. 1 conical generating gear, 2 bevel gear axis, 3 cutter axis, 4 cradle roll axis, 5 cutter depth feed

method. 1 conical generating gear, 2 bevel gear axis, 3 cutter axis, 4 cradle roll axis, 5 cutter depth feed  machine root angle3.2 Manufacturing Kinematics 6 Figure 3.7shows the virtual machine as seen along the axis of rotation of the cradle. For the historical reasons noted above, the term cradle axis is used in preference to virtual crown gear axis. The gure shows only one tooth of the generating gear, where cup-type tool has been substituted. Fig. 3.8 Schematic view of the virtual machine when viewed in direction perpendicular to the bevel gear and cradle axes. cradle roll axis, work piece axis, machine root angle, horizontal distance, sliding base, tBmounting distance, crossing point of axes in the gearbox Fig. 3.7 Schematic view of the virtual machine along the cradle axis . radial distance, swivel angle, tilt angle, offset, work piece axis6 3 Design 3.2.3 Calculation Model The motions between the tool and the work piece may be dened on the basis of Figs. 3.7and3.8. The cradle angle and the cutter angle , which may be independent of each other, are used as command variables. The relativemotion between one crown gear tooth and the work piece may be represented asfollows: radial distance constant swivel angle constant tilt angle constant hypoid offset constant machine root angle constant horizontal distance constant sliding base constant work rotation angle (,) machine center to -point mccp constant More generally, these motions may be described as functions of and: radial distance () swivel angle () tilt angle () hypoid offset () machine root angle () horizontal d

machine root angle3.2 Manufacturing Kinematics 6 Figure 3.7shows the virtual machine as seen along the axis of rotation of the cradle. For the historical reasons noted above, the term cradle axis is used in preference to virtual crown gear axis. The gure shows only one tooth of the generating gear, where cup-type tool has been substituted. Fig. 3.8 Schematic view of the virtual machine when viewed in direction perpendicular to the bevel gear and cradle axes. cradle roll axis, work piece axis, machine root angle, horizontal distance, sliding base, tBmounting distance, crossing point of axes in the gearbox Fig. 3.7 Schematic view of the virtual machine along the cradle axis . radial distance, swivel angle, tilt angle, offset, work piece axis6 3 Design 3.2.3 Calculation Model The motions between the tool and the work piece may be dened on the basis of Figs. 3.7and3.8. The cradle angle and the cutter angle , which may be independent of each other, are used as command variables. The relativemotion between one crown gear tooth and the work piece may be represented asfollows: radial distance constant swivel angle constant tilt angle constant hypoid offset constant machine root angle constant horizontal distance constant sliding base constant work rotation angle (,) machine center to -point mccp constant More generally, these motions may be described as functions of and: radial distance () swivel angle () tilt angle () hypoid offset () machine root angle () horizontal d| Model Type | Bevel-helical gear boxes B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 25700.000000 |

| Ratio Range | 1 : 22.4…80 |

| Low Speed Output | Hollow shaft with spline acc. to DIN 5480 |

| Nominal Torque | 1400000 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | FLENDER ZAHNRADGETRIEBE |

| Country of Manufacture | Belgium |

| Data Sheet & Drawings | B3-KV28-B nting position Type B Gear unit dimensions twosta Bevel-helical gear boxes B3 |