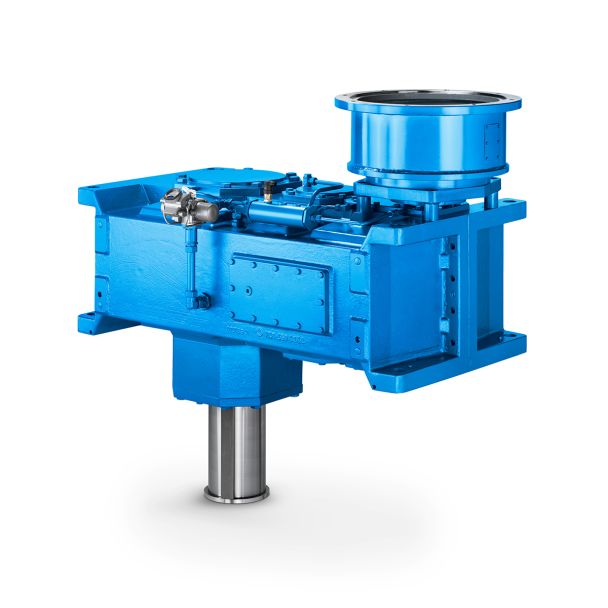

HSS Side Radial shaft sealSide Radial shaft se B3-HV15-B Bevel-helical gear units B3

In stock

SKU

B3-HV15-B

$79,928.57

Flender/Flender Gear Units/Bevel-helical gear units B3

r limit value. Contact Flender regarding deviating temperatures. Stock Flender gear units have modular design. Through this, the variety of components could be reduced. The components are mainly on stock, enabling manufacturing plants worldwide to be delivered at short term.

components could be reduced. The components are mainly on stock, enabling manufacturing plants worldwide to be delivered at short term.  Flender GmbH 2NER GROUP CO.,LIMITED Germany sogears HB series gearbox 2/5 Flender MD 2.1 2 2Introduction Notes Information about basics

Flender GmbH 2NER GROUP CO.,LIMITED Germany sogears HB series gearbox 2/5 Flender MD 2.1 2 2Introduction Notes Information about basics  Overview (continued) Corrosion protection version The Flender standard color RAL5 and an assortment of preferred colors are primarily "silk-matt" and

Overview (continued) Corrosion protection version The Flender standard color RAL5 and an assortment of preferred colors are primarily "silk-matt" and  are applied using solvent-free coating system. The default coloring is comparable to corrosion protection category C3 "medium" according to EN ISO 1-5. Deviating coating systems possible on request. The versions regarding corrosion protection according to the corrosivity categories according to EN ISO1-5 refer to the gear unit itself in the standard program. Add-on parts such as air guides/covers/protective covers made of sheet steel are coated with "signal yellow" powder RAL 1. Flender confirms the suitability of powder-coated built-on components for all corrosion protection classes. An assignment of the corrosivity categories is omitted. This powder-coating is applied independently of the color scheme ordered for the gear unit or the required layer thickness. In the combination of electrostatic attraction between the coat- ing powder and the part to be coated and the melting of this powder by applying heat (between 1 2 ), closed film, the Duroplast color layer, is formed. Powder coating has the following advantages over liquid painting: Better corrosion protection Better chemical resistance Better surface quality, considerably more resistant to impacts, scratches and abrasions Can be immediately used after the surface has cooled down Solvent- and emission-free, therefore very environmentally friendly Considerably lower risk of damage to the color system during assembly processes. This generally

are applied using solvent-free coating system. The default coloring is comparable to corrosion protection category C3 "medium" according to EN ISO 1-5. Deviating coating systems possible on request. The versions regarding corrosion protection according to the corrosivity categories according to EN ISO1-5 refer to the gear unit itself in the standard program. Add-on parts such as air guides/covers/protective covers made of sheet steel are coated with "signal yellow" powder RAL 1. Flender confirms the suitability of powder-coated built-on components for all corrosion protection classes. An assignment of the corrosivity categories is omitted. This powder-coating is applied independently of the color scheme ordered for the gear unit or the required layer thickness. In the combination of electrostatic attraction between the coat- ing powder and the part to be coated and the melting of this powder by applying heat (between 1 2 ), closed film, the Duroplast color layer, is formed. Powder coating has the following advantages over liquid painting: Better corrosion protection Better chemical resistance Better surface quality, considerably more resistant to impacts, scratches and abrasions Can be immediately used after the surface has cooled down Solvent- and emission-free, therefore very environmentally friendly Considerably lower risk of damage to the color system during assembly processes. This generally| Model Type | Bevel-helical gear units B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 3730.000000 |

| Ratio Range | 1 : 12.5…71 |

| Low Speed Output | Hollow shaft with keyway acc. to DIN 6885/1 |

| Nominal Torque | 153000 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | Flender..Ltd China(Tianjin) |

| Country of Manufacture | China |

| Data Sheet & Drawings | HSS Side Radial shaft sealSide Radial shaft se B3-HV15-B Bevel-helical gear units B3 |