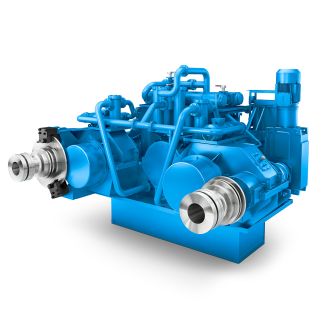

signed to withstand axial forces including those c B3-HV-6B Bevel-helical gear Reduction Boxes B3

In stock

SKU

B3-HV-6B

$10,778.57

Flender/Flender Gear Units/Bevel-helical gear Reduction Boxes B3

r finer air filter and filling sieve Easy oil service Easier draining and filling when changing the oilReliable lubrication Six mounting options for the pressureless oil return for the oil circulation lubrication The right seal Contact and non-contact as well

mounting options for the pressureless oil return for the oil circulation lubrication The right seal Contact and non-contact as well  as encapsulated and non-encapsulated seals to meet your requirements Regulated thermal management Always the right operating temperature with the appropriate

as encapsulated and non-encapsulated seals to meet your requirements Regulated thermal management Always the right operating temperature with the appropriate  heating and cooling solutionsSimple oil level monitoring Service is easy due to quick and reliable oil level reading with an

heating and cooling solutionsSimple oil level monitoring Service is easy due to quick and reliable oil level reading with an  optional integrated scale thermometerDependable temperature control Many ways to install the Pt1 sensor in the gear unit Well-organized electrical components Various terminal boxes form central connection point for sensors and other electrical components Application1 Rotation speedCapacity range 1 1STREAMLINE YOUR PROJECT #4SPEED UP PROJECTSConcentrate only on your design and save valuable time. The FLENDER ONE configurator speaks your language, making it easy for you to satisfy your requirements for your finished product even without gear unit expertise. You also have all the information including 3- data at all times. 3 STEPS TO FINISHED GEAR UNIT Application, capacity range, rotation speed: in principle, with just these three specifications, you can preconfigure your own, specific FLENDER ONE. But even more detailed requirements can be entered in the configura - tion tool by using additional parameters for example, if your gear unit is supposed to be protected from water. We speak your language, we are familiar with your application and we support you with smart configuration that results in just the right gear unit solution for you. gear unit configuration with FLENDER ONE does not depend on any certain point in time, on regional conditions or on differences in howindividual operators use it. If the same information is entered, the same result is returned any time and

optional integrated scale thermometerDependable temperature control Many ways to install the Pt1 sensor in the gear unit Well-organized electrical components Various terminal boxes form central connection point for sensors and other electrical components Application1 Rotation speedCapacity range 1 1STREAMLINE YOUR PROJECT #4SPEED UP PROJECTSConcentrate only on your design and save valuable time. The FLENDER ONE configurator speaks your language, making it easy for you to satisfy your requirements for your finished product even without gear unit expertise. You also have all the information including 3- data at all times. 3 STEPS TO FINISHED GEAR UNIT Application, capacity range, rotation speed: in principle, with just these three specifications, you can preconfigure your own, specific FLENDER ONE. But even more detailed requirements can be entered in the configura - tion tool by using additional parameters for example, if your gear unit is supposed to be protected from water. We speak your language, we are familiar with your application and we support you with smart configuration that results in just the right gear unit solution for you. gear unit configuration with FLENDER ONE does not depend on any certain point in time, on regional conditions or on differences in howindividual operators use it. If the same information is entered, the same result is returned any time and| Model Type | Bevel-helical gear Reduction Boxes B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 503.000000 |

| Ratio Range | 1 : 16…90 |

| Low Speed Output | Hollow shaft with keyway acc. to DIN 6885/1 |

| Nominal Torque | 15500 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | Flender Industriegetriebe GmbH |

| Country of Manufacture | Azerbaijan |

| Data Sheet & Drawings | signed to withstand axial forces including those c B3-HV-6B Bevel-helical gear Reduction Boxes B3 |