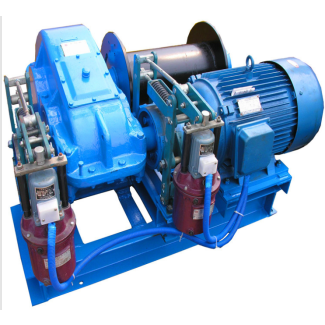

r pump LP GMDXXpE m bsc m an en fpE h h f B3-HH-12-D Bevel-helical speed reduction gearbox B3

In stock

SKU

B3-HH-12-D

$40,714.29

Flender/Flender Gear Units/Bevel-helical speed reduction gearbox B3

process steps, lowerdisposaIcosts,savings on energy and the use of less expensive chemicals and auxiliaries 2. Working steps The project required chemical studies on laboratory scale, in orderto define the basiccharac- teristics of this type of process, equipment-related measures and mechanical,

chemical studies on laboratory scale, in orderto define the basiccharac- teristics of this type of process, equipment-related measures and mechanical,  thermal and electrical tests, in order to be able to assess the reliability of this method and,finally, the Iow- pollution

thermal and electrical tests, in order to be able to assess the reliability of this method and,finally, the Iow- pollution  applicability of the process had to be proven and cost calculations made In the course of the project, it became

applicability of the process had to be proven and cost calculations made In the course of the project, it became  evident that the highly positive results obtained on the laboratory scale could not sim ly be converted to an industrial scale, but led to major difficul- ties The distribution of the derects occurring during electrolytic metallising indicated that the mass transport on the vertical boards had decisive influence on the result For this reason, work had to be continued and completed using pilot plant 8 Laboratory-scale studies It was found that individual holes in PCBs accidentally hung in an acidic galvaniccopper electro- lyte directly after chemical activation were plated through. This result initially contradicted the previous belief that plasticsurface which is coated with isolated precious-metal seeds is an electrically non-conducting substrate which, therefore, can only be electroplated after con- ductive coating is applied to it by chemical reduction. However, on the laborator scale, where the individual process solutions were in beakers, this result could only be repro&ced with unpredictable success.Thus, it was clear that, if the para- meters to be maintained are known, this type of process must be usable for simultaneously coating not only some, but all walls of the holes in PCB with uniform metal film, .. up to approx. 6,0 holes. Thus, in orderto metallise the holes electrolytically, the substrate must be pretreated and cata- lysed. This initially results in the same sequence of process steps as for c

evident that the highly positive results obtained on the laboratory scale could not sim ly be converted to an industrial scale, but led to major difficul- ties The distribution of the derects occurring during electrolytic metallising indicated that the mass transport on the vertical boards had decisive influence on the result For this reason, work had to be continued and completed using pilot plant 8 Laboratory-scale studies It was found that individual holes in PCBs accidentally hung in an acidic galvaniccopper electro- lyte directly after chemical activation were plated through. This result initially contradicted the previous belief that plasticsurface which is coated with isolated precious-metal seeds is an electrically non-conducting substrate which, therefore, can only be electroplated after con- ductive coating is applied to it by chemical reduction. However, on the laborator scale, where the individual process solutions were in beakers, this result could only be repro&ced with unpredictable success.Thus, it was clear that, if the para- meters to be maintained are known, this type of process must be usable for simultaneously coating not only some, but all walls of the holes in PCB with uniform metal film, .. up to approx. 6,0 holes. Thus, in orderto metallise the holes electrolytically, the substrate must be pretreated and cata- lysed. This initially results in the same sequence of process steps as for c| Model Type | Bevel-helical speed reduction gearbox B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 1900.000000 |

| Ratio Range | 1 : 16…90 |

| Low Speed Output | Hollow shaft with keyway acc. to DIN 6885/1 |

| Nominal Torque | 77200 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Flender France S.A.R.L. |

| Country of Manufacture | Morocco |

| Data Sheet & Drawings | r pump LP GMDXXpE m bsc m an en fpE h h f B3-HH-12-D Bevel-helical speed reduction gearbox B3 |