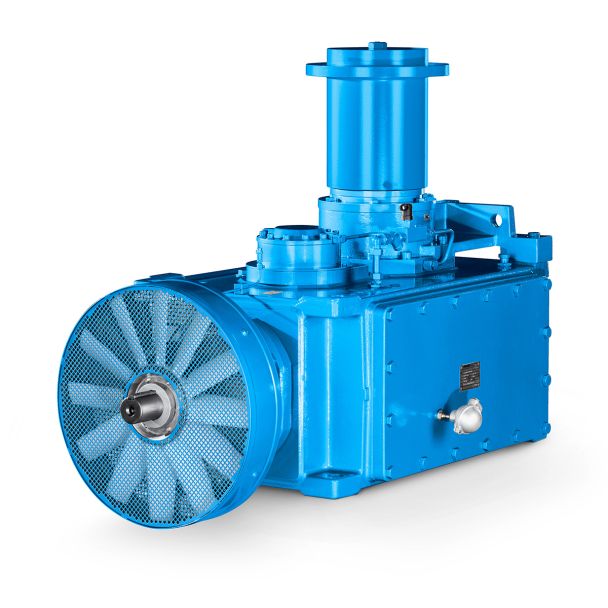

ion Free space for cover please contact us for ex B3-HH14A Bevel-helical gear reducers B3

In stock

SKU

B3-HH14A

$58,928.57

Flender/Flender Gear Units/Bevel-helical gear reducers B3

produce one our, it is referred to as straight run our. When various our streams 3 Sarkar Fig. 3 Flour streams collection. are split two or more ways, the practice is commonly known as split run milling. As can be

streams collection. are split two or more ways, the practice is commonly known as split run milling. As can be  seen in the Fig. 3, after the our streams are separated by sifting, they are directed to our-collecting conveyors through

seen in the Fig. 3, after the our streams are separated by sifting, they are directed to our-collecting conveyors through  appropriate spouting. Generally, there is more than one conveyor. The conveyors are located beneath the sifter oor. The our spouts

appropriate spouting. Generally, there is more than one conveyor. The conveyors are located beneath the sifter oor. The our spouts  arearranged so that they can swivel at the elbow where the spout bends just above the our conveyor. Flour spouts, thus, can be swung from one conveyor to the other. The alternative arrangement for switching our streams involves the use of diverter valves, which allows given our stream to be diverted to any of the our conveyors of choice. Table 1 shows collection of our streams in three groups. The ash contents and protein contents together with the proportions of each our stream for this example aretaken from Table 9. In practice, our streams with similar properties are combined into corresponding our conveyors. In this example, three our conveyors are used, providing three combinations of the original 1 our streams. Table 1, thus, shows our proportion,ash, and protein content of the three combinations, designated 1, 2, and 3. If, instead, theour streams in Table 9 were combined in sequence, the ash content and protein contentof the cumulative our at each step would be shown by the cumulative ash and cumu-lative protein. Thus, the straight grade our (last line) would have an ash content of 0.5% and protein content of 1.8%. In Canada, our millers use device called divide board, that provides an additional level of control whereby ours leaving the conveyors may be further dividedor recombined as desired. This process is referred to as divide milling. divide board is equipped with diverter valves. The number of inlets as well as outlets on divide board is same as the number of conveyors. If all the diver

arearranged so that they can swivel at the elbow where the spout bends just above the our conveyor. Flour spouts, thus, can be swung from one conveyor to the other. The alternative arrangement for switching our streams involves the use of diverter valves, which allows given our stream to be diverted to any of the our conveyors of choice. Table 1 shows collection of our streams in three groups. The ash contents and protein contents together with the proportions of each our stream for this example aretaken from Table 9. In practice, our streams with similar properties are combined into corresponding our conveyors. In this example, three our conveyors are used, providing three combinations of the original 1 our streams. Table 1, thus, shows our proportion,ash, and protein content of the three combinations, designated 1, 2, and 3. If, instead, theour streams in Table 9 were combined in sequence, the ash content and protein contentof the cumulative our at each step would be shown by the cumulative ash and cumu-lative protein. Thus, the straight grade our (last line) would have an ash content of 0.5% and protein content of 1.8%. In Canada, our millers use device called divide board, that provides an additional level of control whereby ours leaving the conveyors may be further dividedor recombined as desired. This process is referred to as divide milling. divide board is equipped with diverter valves. The number of inlets as well as outlets on divide board is same as the number of conveyors. If all the diver| Model Type | Bevel-helical gear reducers B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 2750.000000 |

| Ratio Range | 1 : 16…90 |

| Low Speed Output | Hollow shaft with keyway acc. to DIN 6885/1 |

| Nominal Torque | 113000 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Flender Brasil Ltda |

| Country of Manufacture | New Zealand |

| Data Sheet & Drawings | ion Free space for cover please contact us for ex B3-HH14A Bevel-helical gear reducers B3 |