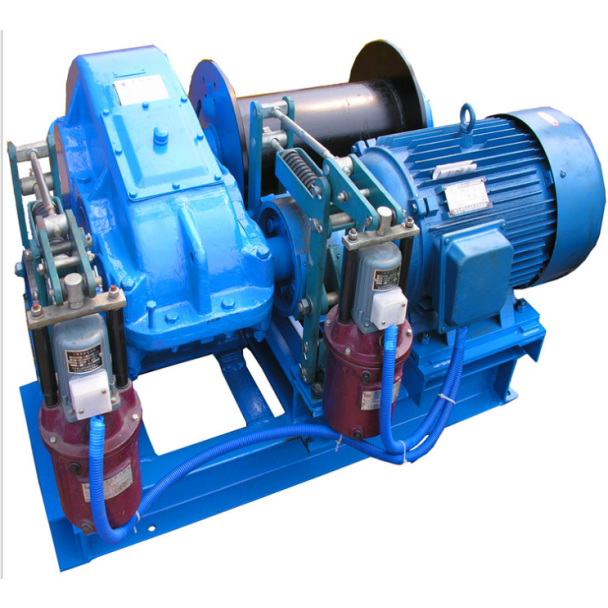

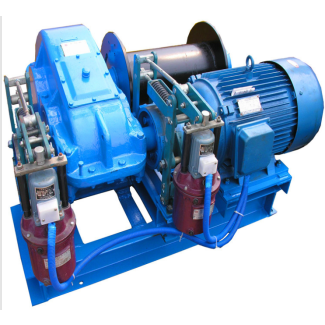

h LSSdl G GMDXXB For details on the shafts see Ch B3-HH-13-A Bevel-helical gear Reduction Box B3

In stock

SKU

B3-HH-13-A

$51,000.00

Flender/Flender Gear Units/Bevel-helical gear Reduction Box B3

process was to replace the methods currently in use cleaning baths), 2. Working steps Various fluidised-bed configurations were tested according to detailed list of criteria and optimised to suit the requirements. Four fields of application were examined: 1. Thermal degreasing.

to detailed list of criteria and optimised to suit the requirements. Four fields of application were examined: 1. Thermal degreasing.  2. Targeted oxidationlreduction to produce protective coatings. 3. Thermal stripping to clean incorrectly coated or extremely dirty parts. 4. Chemical

2. Targeted oxidationlreduction to produce protective coatings. 3. Thermal stripping to clean incorrectly coated or extremely dirty parts. 4. Chemical  decomposition of liquid waste with an exacttemperature profile, long dwelltime The expected environmental pollutants were documented. The optimum process arameters

decomposition of liquid waste with an exacttemperature profile, long dwelltime The expected environmental pollutants were documented. The optimum process arameters  for the respective requirements were defined, in order to obtain the best possibE treatment results with the minimum material and energy input. complete pilot plant has been installed, .. with inert gas conditioning and fluidised bed, in- cluding thermal postincineration. Annealin and stripping trials were carried out after obtaining an operatin permit from the TUV (Tecznical Inspection Association) and the factory inspectorate, and wit1 the cooperation of the Land Office for Emissions Control. mobile installation (including mobile analytical equipment) was constructed for the trials. and reductive atmosphere. 9 3. Results At temperatures between 9 and 9 ", with an average dwell time of 2 seconds and in variable inert gas atmosphere with 8% to 1% H2, halogens are initially eliminated as hydro- gen halides from the hydrogen halides used The carbon skeleton subsequently breaks down and forms gaseous cracking roducts Chemically bound heteroatoms, such as oxygen, are also eliminated Chlorinated cfbenzodioxins and dibenzofurans, which are of particular relev- ance as re ards environmental protection, cannot form in this reductive atmosphere These compounfs can even be disposed of in this installation Extruder screens with polypropylene build-up were successfully cleaned in the fluidised bed The treatment was carried out at temperatures between 4 and 5 OC

for the respective requirements were defined, in order to obtain the best possibE treatment results with the minimum material and energy input. complete pilot plant has been installed, .. with inert gas conditioning and fluidised bed, in- cluding thermal postincineration. Annealin and stripping trials were carried out after obtaining an operatin permit from the TUV (Tecznical Inspection Association) and the factory inspectorate, and wit1 the cooperation of the Land Office for Emissions Control. mobile installation (including mobile analytical equipment) was constructed for the trials. and reductive atmosphere. 9 3. Results At temperatures between 9 and 9 ", with an average dwell time of 2 seconds and in variable inert gas atmosphere with 8% to 1% H2, halogens are initially eliminated as hydro- gen halides from the hydrogen halides used The carbon skeleton subsequently breaks down and forms gaseous cracking roducts Chemically bound heteroatoms, such as oxygen, are also eliminated Chlorinated cfbenzodioxins and dibenzofurans, which are of particular relev- ance as re ards environmental protection, cannot form in this reductive atmosphere These compounfs can even be disposed of in this installation Extruder screens with polypropylene build-up were successfully cleaned in the fluidised bed The treatment was carried out at temperatures between 4 and 5 OC| Model Type | Bevel-helical gear Reduction Box B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 2380.000000 |

| Ratio Range | 1 : 12.5…71 |

| Low Speed Output | Hollow shaft with keyway acc. to DIN 6885/1 |

| Nominal Torque | 90700 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Flender France S.A.R.L. |

| Country of Manufacture | China |

| Data Sheet & Drawings | h LSSdl G GMDXXB For details on the shafts see Ch B3-HH-13-A Bevel-helical gear Reduction Box B3 |