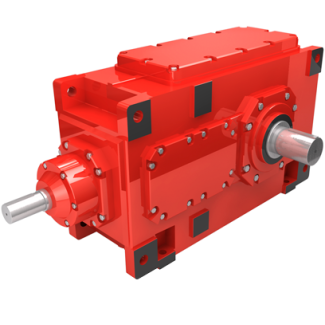

ition see pages to Article No LP Type B3-DH-28B Bevel-helical gear boxes B3

In stock

SKU

B3-DH-28B

$550,714.29

Flender/Flender Gear Units/Bevel-helical gear boxes B3

red and that received Basic cleaning to remove: Large objects that may block the bin outlets or damage downstream equipmentFine material and dust that could hamper the ow of wheat, may harbor infesta- tion, cause respiratory problems, cause malfunctioning of

material and dust that could hamper the ow of wheat, may harbor infesta- tion, cause respiratory problems, cause malfunctioning of  equipment compo- nents, such as bearings, and possibly contribute to dust explosions Identity preservation of all wheat received The process

equipment compo- nents, such as bearings, and possibly contribute to dust explosions Identity preservation of all wheat received The process  of wheat intake begins as the grain is dumped into pit that has metal grate on top to prevent any

of wheat intake begins as the grain is dumped into pit that has metal grate on top to prevent any  large chunks or oversized foreign material, such as wood,metal, stones, or other), from entering the precleaning system. The hopper of the pit chan-nels the wheat through chute to conveying element that brings the wheat to weigh scale. The chute between the hopper and the conveying element, which most commonly is bucket elevator, is usually slide that may be adjusted to regulate the ow of grainthrough the intake process. Also provided at this point is magnet that will prevent anytramp ferrous metal to pass through. Underneath the weighing scale there is generally asurge bin equipped with low- and high-level indicators. As the level in the bin goes downbelow the low-level, the process starts, and when it goes above the high-level the process stops. This ensures constant ow of grain through the system. The grain is next fed into grain separator which removes coarse, large-sized foreign material, as well as ne mate-rial such as dirt, sand, and lighter foreign material, such as chaff, husk, and such. Thegrain separator consists of two screens: the one on top has larger opening than the wheatsize, whereas the one at the bottom has ner perforations to allow only the very nematerial, such as dust, sand, and the like, to pass through. The grain falls through the top screen and goes over the bottom screen into an aspiration channel. feeding mechanism ensures that the grain is fed uniformly and evenly across the width of the channel in athin layer to allow effective exposure

large chunks or oversized foreign material, such as wood,metal, stones, or other), from entering the precleaning system. The hopper of the pit chan-nels the wheat through chute to conveying element that brings the wheat to weigh scale. The chute between the hopper and the conveying element, which most commonly is bucket elevator, is usually slide that may be adjusted to regulate the ow of grainthrough the intake process. Also provided at this point is magnet that will prevent anytramp ferrous metal to pass through. Underneath the weighing scale there is generally asurge bin equipped with low- and high-level indicators. As the level in the bin goes downbelow the low-level, the process starts, and when it goes above the high-level the process stops. This ensures constant ow of grain through the system. The grain is next fed into grain separator which removes coarse, large-sized foreign material, as well as ne mate-rial such as dirt, sand, and lighter foreign material, such as chaff, husk, and such. Thegrain separator consists of two screens: the one on top has larger opening than the wheatsize, whereas the one at the bottom has ner perforations to allow only the very nematerial, such as dust, sand, and the like, to pass through. The grain falls through the top screen and goes over the bottom screen into an aspiration channel. feeding mechanism ensures that the grain is fed uniformly and evenly across the width of the channel in athin layer to allow effective exposure| Model Type | Bevel-helical gear boxes B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 25700.000000 |

| Ratio Range | 1 : 22.4…80 |

| Low Speed Output | Hollow shaft with shrink disk |

| Nominal Torque | 1400000 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | A. FRIEDR. FLENDER AG |

| Country of Manufacture | Denmark |

| Data Sheet & Drawings | ition see pages to Article No LP Type B3-DH-28B Bevel-helical gear boxes B3 |