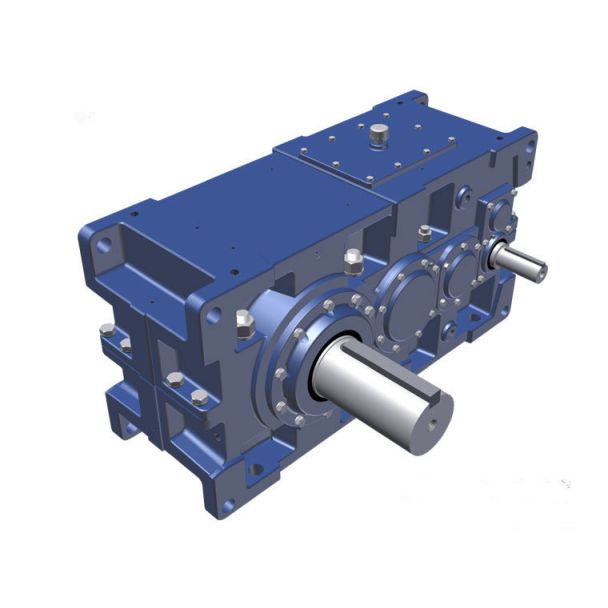

Cooling options see page onwards Approxim B3-DV4-B Bevel-helical gear Reduction Boxes B3

In stock

SKU

B3-DV4-B

$10,178.57

Flender/Flender Gear Units/Bevel-helical gear Reduction Boxes B3

reduced running noise can be achieved through the least possible radial and angular misalignment. NOTICE Property damage Damage to the gear unit or individual components is possible from inadequate alignment.When setting up the drives for the alignment of the individual

gear unit or individual components is possible from inadequate alignment.When setting up the drives for the alignment of the individual  components, observe the specificationsin the related instructions for the components. Unacceptable large errors in the alignment of the shaft ends

components, observe the specificationsin the related instructions for the components. Unacceptable large errors in the alignment of the shaft ends  to be connected due to angular and/or axial misalignments result in premature wear and material damage.When using gear couplings, defined

to be connected due to angular and/or axial misalignments result in premature wear and material damage.When using gear couplings, defined  alignment deviation might be necessary, please observe theinstructions for the gear couplings.Insufficiently rigid base frames or sub-structures can also cause radial and/or axial misalignmentduring operation, which cannot be measured when the unit is at standstill. Note For permissible alignment errors in couplings supplied by Siemens, refer to the instructions manualsfor the couplings.When using couplings manufactured by other manufacturers, ask these manufacturers which alignment errors are permissible, stating the radial loads occurring. The coupling parts may get out of alignment: by imprecise alignment during assembly or installation, during operation of the system due to: due to heat expansion, due to shaft flexure, due to too weak machine frames, etc. Ka Kw Kr Axial misalignment (Ka)Angular misalignment (Kw)Radial misalignment (Kr) Fig. 3: Possible misalignments 6 / 9BA 5 en 0/2Alignment has to be done in two axial planes arranged perpendicularly to each other. This can be done by means of ruler (radial misalignment) and feeler gauge (angular misalignment), as shown in the illustration. The aligning accuracy can be increased by using dial gauge or laser alignment system. 3 1 Fig. 3: Example of alignment on flexible coupling 1 Ruler 2 Feeler gauge3 Measuring points NOTICE Property damage Damage or destruction of the coupling from wrong alignment is possible. The maximum permissible misalignment values

alignment deviation might be necessary, please observe theinstructions for the gear couplings.Insufficiently rigid base frames or sub-structures can also cause radial and/or axial misalignmentduring operation, which cannot be measured when the unit is at standstill. Note For permissible alignment errors in couplings supplied by Siemens, refer to the instructions manualsfor the couplings.When using couplings manufactured by other manufacturers, ask these manufacturers which alignment errors are permissible, stating the radial loads occurring. The coupling parts may get out of alignment: by imprecise alignment during assembly or installation, during operation of the system due to: due to heat expansion, due to shaft flexure, due to too weak machine frames, etc. Ka Kw Kr Axial misalignment (Ka)Angular misalignment (Kw)Radial misalignment (Kr) Fig. 3: Possible misalignments 6 / 9BA 5 en 0/2Alignment has to be done in two axial planes arranged perpendicularly to each other. This can be done by means of ruler (radial misalignment) and feeler gauge (angular misalignment), as shown in the illustration. The aligning accuracy can be increased by using dial gauge or laser alignment system. 3 1 Fig. 3: Example of alignment on flexible coupling 1 Ruler 2 Feeler gauge3 Measuring points NOTICE Property damage Damage or destruction of the coupling from wrong alignment is possible. The maximum permissible misalignment values| Model Type | Bevel-helical gear Reduction Boxes B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 475.000000 |

| Ratio Range | 1 : 12.5…71 |

| Low Speed Output | Hollow shaft with shrink disk |

| Nominal Torque | 6700 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | N.V. Flender Belge S.A. |

| Country of Manufacture | China |

| Data Sheet & Drawings | Cooling options see page onwards Approxim B3-DV4-B Bevel-helical gear Reduction Boxes B3 |