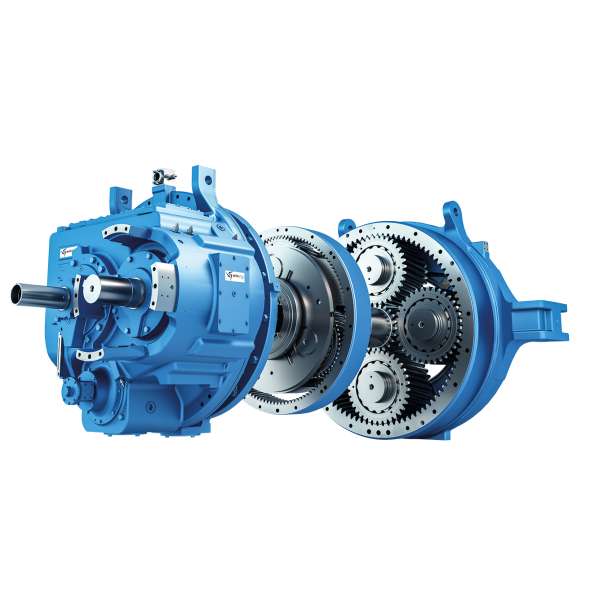

B3-CV-20-D C Type Size NDIN D D G l kg Hollow shaft with Bevel-helical gear reducer B3

In stock

SKU

B3-CV-20-D

$173,571.43

Flender/Flender Gear Units/Bevel-helical gear reducer B3

pherical particles (/) can be calculated (1, from Eqs. ( and (: Vf/H1(/H1a) d2 p3 1(1/H( and Ve/H1/H2dp(/H1a) 3Cda/H2/2 ( wheresandaare the densities (kg/m of solid particles and gas, respectively; dpis the diameter of the particle (); is the void

wheresandaare the densities (kg/m of solid particles and gas, respectively; dpis the diameter of the particle (); is the void  fraction of the bed; is the viscosity of air (kg/ /H;Cdis the drag coefcient (which is 0.4 for Reynolds number

fraction of the bed; is the viscosity of air (kg/ /H;Cdis the drag coefcient (which is 0.4 for Reynolds number  of the air in the range of 5,0); gis acceleration due to gravity (/s; andis sphericity of the particle. For

of the air in the range of 5,0); gis acceleration due to gravity (/s; andis sphericity of the particle. For  low Reynolds number, both VeandVfvary with d2 ,(/H1a), and 1/. Thus, the ratio of Ve/Vfdepends on mainly the void fraction at minimum uidiza- tion (; thus, Ve Vf/H1.3(1/H 2( For nonspherical particles is less than 1, and is greater than 0.4 (approximate value for spherical particles is 0.. For large-shaped spherical grains with Reynolds numberhigher than 1 3, the ratio of velocities is Ve Vf/H1.3 3/2( The pressure drop ( ) per unit bed height ( ) (Pa/) at minimum uidization velocity can be expressed as /H1g(1/H(/H1a) ( Grain-Drying Systems 1 The upper limit of gas ow rate is often determined by the loss of ne product with the exhaust gas (. For drying of grain in uidized bed, perforated plate bed-support is sufcient, and the system is usually operated at atmospheric pressure, although operations above or belowatmospheric pressures are possible (. Better management of drying condition can be accomplished in batch-operated uidized bed dryer. However, batch units are suitable for small-scale operation. Two types of continuous uidized bed drying are practiced (.., plug-ow uidized bed dryer and well-mixed uidized bed dryer). In the former, the feed is introduced atone end (wet end) and the product moves forward in plug-ow pattern until they aredischarged at the other end (dry end) over an adjustable weir (Fig. . uniform drying is accomplished because of relatively narrow distribution of residence time of the particles in the bed. However, the system has limited applica

low Reynolds number, both VeandVfvary with d2 ,(/H1a), and 1/. Thus, the ratio of Ve/Vfdepends on mainly the void fraction at minimum uidiza- tion (; thus, Ve Vf/H1.3(1/H 2( For nonspherical particles is less than 1, and is greater than 0.4 (approximate value for spherical particles is 0.. For large-shaped spherical grains with Reynolds numberhigher than 1 3, the ratio of velocities is Ve Vf/H1.3 3/2( The pressure drop ( ) per unit bed height ( ) (Pa/) at minimum uidization velocity can be expressed as /H1g(1/H(/H1a) ( Grain-Drying Systems 1 The upper limit of gas ow rate is often determined by the loss of ne product with the exhaust gas (. For drying of grain in uidized bed, perforated plate bed-support is sufcient, and the system is usually operated at atmospheric pressure, although operations above or belowatmospheric pressures are possible (. Better management of drying condition can be accomplished in batch-operated uidized bed dryer. However, batch units are suitable for small-scale operation. Two types of continuous uidized bed drying are practiced (.., plug-ow uidized bed dryer and well-mixed uidized bed dryer). In the former, the feed is introduced atone end (wet end) and the product moves forward in plug-ow pattern until they aredischarged at the other end (dry end) over an adjustable weir (Fig. . uniform drying is accomplished because of relatively narrow distribution of residence time of the particles in the bed. However, the system has limited applica| Model Type | Bevel-helical gear reducer B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 8100.000000 |

| Ratio Range | 1 : 14…80 |

| Low Speed Output | Solid shaft without parallel key |

| Nominal Torque | 345000 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | Flender GmbH |

| Country of Manufacture | Canada |

| Data Sheet & Drawings | B3-CV-20-D C Type Size NDIN D D G l kg Hollow shaft with Bevel-helical gear reducer B3 |